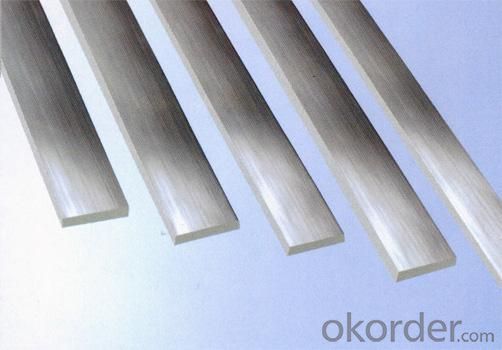

Steel flat bar steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel flat bar steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel flat bar steel flat bar for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel flat bar steel flat bar for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of city overpass steel structure

Project type: city overpass

Bridge height: 5M

Span: 60M

Design load: crowd 4.5KN/M2, one-side handrail 5.0 KN/m

Structure type: the main bridge is continuous girder bridge, with one stairway at both ends. The main bridge adopts three-span layout. Stairways are made of continuous steel girder structure.

1. GB standard material

2. High Structural safety and reliability

3. The production can reach GB/JIS/ISO/ASME standard

Packaging & Delivery of city overpass steel structure

1. According to the project design and the component size, usually the main component parts are nude packing and shipped by bulk vessel. And the small parts are packed in box or suitable packages and shipped by containers.

2. This will be communicated and negotiated with buyer according to the design.

Engineering Design Software of city overpass steel structure

Tekla Structure \ AUTO CAD \ PKPM software etc

⊙Complex spatial structure project detailed design

⊙Construct 3D-model and structure analysis. ensure the accuracy of the workshop drawings

⊙Steel structure detail ,project management, automatic Shop Drawing, BOM table automatic generation system.

⊙Control the whole structure design process, we can obtain higher efficiency and better results

Technical support of city overpass steel structure

Worker | Rate of frontline workers with certificate on duty reaches 100% |

Welder | 186 welders got AWS & ASME qualification 124 welders got JIS qualification 56 welders got DNV &BV qualification |

Technical inspector | 40 inspectors with UT 2 certificate 10 inspectors with RT 2 certificate 12 inspectors with MT 2 certificate 3 inspectors with UT3 certificate |

Engineer | 21 engineers with senior title 49 engineers with medium title 70 engineers with primary title. 61 First-Class Construction Engineers 182 Second-Class Construction Engineers |

International certification | 10 engineers with International Welding engineer, 8 engineers with CWI. |

Production Flow of steel structure/steel frame/steel construction

Material preparation—cutting—fitting up—welding—component correction—rust removal—paint coating—packing—to storage and transportation (each process has the relevant inspection)

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: How are steel structures used in the construction of commercial buildings?

- Steel structures are commonly used in the construction of commercial buildings due to their strength, durability, and cost-effectiveness. They provide a sturdy framework that can support large spans and heavy loads, allowing for open and flexible floor plans. Steel beams, columns, and trusses are used to create the structural frame of the building, providing stability and ensuring the safety of occupants. Additionally, steel is fire-resistant, which adds to the overall safety of the structure. Overall, steel structures offer numerous advantages in terms of design flexibility, construction speed, and long-term maintenance, making them a popular choice for commercial building construction.

- Q: What are the energy efficiency benefits of using steel in structures?

- Using steel in structures offers several energy efficiency benefits. Firstly, steel is a highly durable and long-lasting material, which reduces the need for frequent repairs or replacements. This results in lower energy consumption and less waste generated over the lifespan of the structure. Additionally, steel has excellent thermal properties, allowing for better insulation and reduced energy requirements for heating and cooling. Furthermore, steel can be recycled infinitely without any loss in quality, making it a sustainable and environmentally-friendly choice. Overall, the energy efficiency benefits of using steel in structures contribute to lower energy costs, reduced environmental impact, and increased sustainability.

- Q: How are steel structures resistant to fire?

- Steel structures are resistant to fire due to the inherent properties of steel. Steel has a high melting point, which means it can withstand extremely high temperatures without losing its structural integrity. Additionally, steel does not burn or contribute to the spread of fire, unlike other building materials such as wood or plastics. Furthermore, steel structures can be designed with fire-resistant coatings or insulation materials that provide additional protection and prolong the time it takes for the steel to heat up. Overall, these factors make steel structures highly resistant to fire and ensure the safety of occupants during a fire incident.

- Q: How are steel beams connected to columns?

- Various methods are used to connect steel beams to columns, depending on specific design requirements and load conditions. Welding is a commonly employed technique, where the steel beam is directly welded to the column, creating a strong and durable connection capable of withstanding significant loads. Bolted connections are another frequently utilized method. Steel plates are welded or bolted to the ends of the beam and column, and bolts are used to connect these plates together. This type of connection allows for easier disassembly and modification, if necessary. A hybrid connection, which combines welding and bolting, is also employed in some cases. This method offers the advantages of both techniques, ensuring a secure and reliable connection. In addition, specialized connection systems, such as moment connections, are available for specific needs. These connections involve additional reinforcement and are designed to resist high loads and bending moments while transferring them between the beam and the column. Ultimately, the choice of how to connect steel beams to columns depends on factors such as structural design, load requirements, and project specifications. Structural engineers carefully evaluate these factors to determine the most suitable connection method that guarantees the integrity and stability of the structure.

- Q: The longitudinal force of a steel column supported by a steel column

- The material has good plasticity and toughness, and can have large deformation, can well withstand dynamic loads; short construction period; the high degree of industrialization, can carry out specialized production of high degree of mechanization; the processing of high precision, high efficiency, good sealing performance, so it can be used in the construction of tank, tank and transformer etc..

- Q: What are the considerations for the design of steel structures in areas with high seismic activity?

- When designing steel structures in areas with high seismic activity, there are several crucial considerations to keep in mind. Firstly, it is essential to employ a robust structural system that can effectively dissipate and absorb seismic energy, such as moment-resisting frames or braced frames. These systems provide the necessary flexibility and strength to withstand seismic forces. Secondly, the choice of materials becomes vital. High-quality steel with excellent ductility and toughness is preferred as it can deform and absorb energy during an earthquake without losing its load-carrying capacity. Reinforcing elements, such as steel plates or shear walls, may also be incorporated to enhance the structure's resistance to seismic forces. Moreover, proper detailing and connections play a significant role in ensuring structural integrity during seismic events. Connections between beams, columns, and other elements need to be carefully designed and adequately reinforced to resist the lateral forces generated by earthquakes. Additionally, employing seismic dampers or isolators can further enhance the structure's ability to withstand seismic activity. Lastly, adherence to relevant building codes and regulations specific to seismic design is crucial. These codes provide guidelines for designing structures that can withstand predetermined levels of seismic activity, ensuring the safety of occupants and minimizing damage to the building. Overall, the design of steel structures in high seismic areas necessitates a combination of appropriate structural systems, high-quality materials, detailed connections, and adherence to seismic design codes. By considering these factors, engineers can create resilient structures that can effectively withstand the forces generated by earthquakes.

- Q: What does the horizontal support of steel structure mean?

- When it comes to brace generally refers to Rachel steel purlin, it is reinforced, but also to enhance the stability of the purlin purlin, not easy to lose in the external force under certain failure. Section purlin are generally H steel, C shape, Z shape, is reducing cabin panel span and fixed roof panel.

- Q: What are the steps involved in erecting a steel structure?

- Erecting a steel structure involves several important steps to ensure a safe and successful construction process. Here are the general steps involved in erecting a steel structure: 1. Planning and Design: The first step is to thoroughly plan and design the steel structure. This includes determining the purpose of the structure, considering the load-bearing requirements, and creating detailed blueprints and construction drawings. 2. Site Preparation: Before starting the construction, the site needs to be prepared. This involves clearing the area, leveling the ground, and ensuring proper drainage. 3. Foundation Construction: The next step is to construct the foundation for the steel structure. This typically involves excavating the ground, pouring concrete footings or piers, and installing anchor bolts to secure the steel columns. 4. Steel Fabrication: While the foundation is being constructed, the steel components are fabricated off-site. This includes cutting, welding, and shaping the steel beams, columns, trusses, and other structural elements according to the design specifications. 5. Delivery and Unloading: Once the steel components are ready, they are delivered to the construction site. Proper unloading techniques are employed to ensure the safety of workers and prevent any damage to the steel components. 6. Assembly and Erection: The actual assembly and erection of the steel structure begin at this stage. The steel columns and beams are lifted into position using cranes or other heavy lifting equipment. The connections between the various steel elements are bolted or welded together, ensuring structural integrity. 7. Bracing and Stabilization: As the structure is being erected, temporary bracing is installed to provide stability and prevent any movement or collapse during construction. This includes cross bracing, diagonal bracing, and temporary support systems. 8. Roof and Wall Installation: Once the structural frame is complete, the roof and wall panels are installed. These panels can be made of steel, glass, or other materials, depending on the design requirements. 9. Finishing and Detailing: After the main structure is erected, finishing touches are added. This includes installing doors, windows, insulation, electrical and plumbing systems, and other necessary components. 10. Inspections and Safety Checks: Throughout the construction process, inspections are conducted to ensure compliance with building codes and safety regulations. This includes structural inspections, fire safety checks, and quality control assessments. 11. Finalizing and Handover: The final step involves conducting a thorough inspection of the completed steel structure. If everything meets the required standards, the project is considered complete, and the structure is handed over to the owner or client. It is important to note that the specific steps involved may vary depending on the complexity and scale of the steel structure being erected. Additionally, it is crucial to follow all safety protocols and regulations throughout the entire construction process to ensure the well-being of workers and the integrity of the structure.

- Q: What are the different types of steel staircase systems used in building structures?

- There are several different types of steel staircase systems that are commonly used in building structures. These systems are designed to provide safe and efficient access between floors, and they can be customized to suit the specific needs and aesthetics of a building. 1. Straight Staircase: This is the most basic and commonly used type of steel staircase system. It consists of a straight flight of stairs that connects two floors in a straight line. Straight staircases are simple, functional, and easy to construct. 2. L-Shaped Staircase: This type of staircase system is characterized by a 90-degree turn in the middle, forming an L-shape. L-shaped staircases are often used in buildings where space is limited or where there is a need to change the direction of the staircase. 3. U-Shaped Staircase: Similar to the L-shaped staircase, the U-shaped staircase features a 180-degree turn, forming a U-shape. This type of staircase is commonly seen in large buildings where space is not a constraint. It allows for a smooth and continuous flow of traffic between floors. 4. Spiral Staircase: Spiral staircases are known for their unique design that features a central column and steps that wind around it in a circular or spiral pattern. These staircases are popular in buildings with limited space or for decorative purposes. They can be made of steel for added strength and durability. 5. Floating Staircase: Also known as cantilevered stairs, floating staircases create an illusion of floating in mid-air. They are attached to a wall or a supporting structure without the need for visible supports or risers. These staircases are visually appealing and can add a modern and minimalist touch to a building. 6. Industrial Staircase: Industrial staircases are designed to withstand heavy usage and are commonly found in factories, warehouses, and industrial buildings. They are usually made of steel for maximum strength and durability. These staircases often feature open risers and grated treads to allow for easy cleaning and drainage. Overall, the choice of steel staircase system depends on various factors such as available space, building design, functionality, and aesthetic preferences. Each type of staircase offers its own advantages and can be customized to meet the specific requirements of a building structure.

- Q: Why can't epoxy paint be used in outdoor steel structures?

- Epoxy paint used as primer, iron red epoxy primer, epoxy zinc primer can be matched with acrylic polyurethane paint, fluorocarbon paint, etc. for outdoor weatherproof coating.

Send your message to us

Steel flat bar steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords