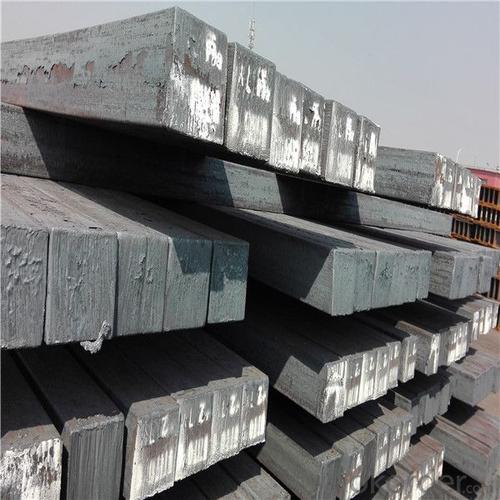

Grade Q215 super square steel billet form China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17172 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still

require a series of shaping and molding procedures such as hot and cold working, milling and cutting

before they are sold in hardware stores, or used for different applications. The unformed billets,

however, can be used in striking currency such as coins and as reserves, similar to gold bars.

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

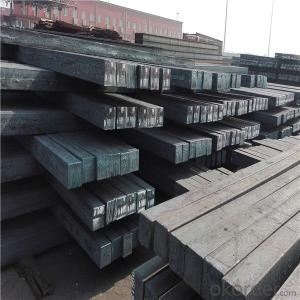

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: Can steel billets be used in the production of medical equipment?

- Yes, steel billets can be used in the production of medical equipment. Steel is known for its strength, durability, and resistance to corrosion, making it an ideal material for manufacturing various medical devices. Steel billets, which are the initial semi-finished product of steel production, can be further processed and shaped into specific components or parts required for medical equipment. These components can include surgical instruments, implants, orthopedic devices, needles, and other medical tools. Steel's mechanical properties and ability to withstand sterilization processes make it a suitable choice for producing safe and reliable medical equipment.

- Q: the ear has burrs, is it the billet problem or the rolling mill problem, will it be caused by the blowhole of the billet?

- The rolling process of rolling mill of hot rolling and cold rolling process for the two step: a hot rolling process: from out of billet steel plant is only semi-finished products, to the rolling mill for rolling, in order to become a qualified product.

- Q: What are the challenges in welding steel billets?

- There are several challenges that can arise when welding steel billets. One of the main challenges is ensuring proper heat distribution during the welding process. Steel billets are often large and thick, which can make it difficult to evenly distribute heat throughout the material. This can result in inconsistencies in the weld, leading to weak spots or even failure of the joint. Another challenge is the potential for distortion and warping of the billet during the welding process. As heat is applied to the steel, it can cause the material to expand and contract, leading to unwanted changes in shape and dimensions. This can be particularly problematic when welding large or complex structures, as maintaining the desired shape and dimensions becomes critical. Additionally, steel billets can contain impurities and contaminants that can affect the quality of the weld. These impurities, such as sulfur, phosphorus, and other elements, can lead to the formation of brittle zones or other defects in the weld. Proper cleaning and preparation of the billet surface, as well as using appropriate welding techniques and filler materials, are necessary to mitigate these challenges. Furthermore, the high carbon content often found in steel billets can make them prone to cracking during the welding process. Carbon acts as a hardening agent in steel and can increase its susceptibility to cracking, especially if proper preheating and post-weld heat treatment procedures are not followed. Controlling the cooling rate and implementing stress-relieving techniques are essential in preventing cracking and ensuring the integrity of the weld. Lastly, the sheer size and weight of steel billets can present logistical challenges during the welding process. Handling and positioning these heavy objects require specialized equipment and skilled operators to ensure safety and accuracy. Additionally, the need for precise alignment and fit-up can be more challenging with large billets, requiring careful planning and execution. In conclusion, welding steel billets poses challenges such as heat distribution, distortion and warping, impurities and contaminants, carbon-induced cracking, and logistical issues. Overcoming these challenges requires expertise, proper equipment, and adherence to appropriate welding techniques and procedures.

- Q: What is the average density of a steel billet?

- The average density of a steel billet can vary depending on the specific grade and composition of the steel used. However, on average, the density of a steel billet ranges from around 7,800 to 8,050 kilograms per cubic meter (kg/m³). This density value is higher compared to many other materials, making steel a dense and heavy material. The density of a steel billet is a crucial factor to consider when determining its weight, volume, and overall structural properties.

- Q: Are steel billets used in the production of construction equipment?

- Yes, steel billets are commonly used in the production of construction equipment. Steel billets are semi-finished steel products that are typically hot-rolled or forged into various shapes and sizes. These billets serve as the raw material for manufacturing construction equipment components, such as beams, plates, rods, and structural parts. The use of steel billets in construction equipment ensures the durability, strength, and reliability of the final product, making it suitable for heavy-duty applications in the construction industry.

- Q: What is the role of steel billets in the construction of dams and reservoirs?

- The role of steel billets in dam and reservoir construction cannot be overstated. These semi-finished steel products are vital for manufacturing various components and structures necessary for the construction process. A primary application of steel billets in dam and reservoir construction is their use in producing reinforced concrete. Reinforced concrete combines the strength and durability of steel with the versatility and moldability of concrete. Steel billets are utilized to create steel reinforcement bars, commonly called rebars, which are embedded within the concrete to improve its tensile strength and prevent cracking when subjected to heavy loads. These rebars provide the necessary structural support for the dam or reservoir, ensuring its stability and long life. Furthermore, steel billets are essential for fabricating gates, penstocks, and other mechanical components required for dams and reservoirs. These components play a crucial role in regulating water flow, controlling water levels, and managing the release of water from the reservoir. Steel billets are forged, rolled, or machined to manufacture these specialized components, guaranteeing their strength, reliability, and resistance to corrosion. Moreover, steel billets are indispensable in constructing spillways, which are designed to safely discharge excess water from reservoirs during periods of heavy rainfall or floods. Spillway gates, channels, and other structures are often made from steel billets because they need to withstand high water pressure and turbulent flow conditions. To summarize, steel billets are vital in dam and reservoir construction. They are instrumental in producing reinforced concrete, thereby providing structural support and enhancing the overall strength of the structure. Steel billets are also used in the production of gates, penstocks, spillways, and other mechanical components, ensuring the efficient operation and long-term durability of these crucial water management infrastructures.

- Q: How are steel billets used in construction?

- Steel billets are used in construction to produce various structural components such as beams, columns, and bars. They are first heated and then shaped into the desired form through processes like rolling or extrusion. These components provide strength and stability to buildings, making them essential for supporting and reinforcing structures in construction projects.

- Q: Billet prices skyrocketing weekend, Southern China steel prices rose?

- So, three month contract period, even transportation during two days, there will be a big money and lose big reversal.

- Q: How are steel billets used in the manufacturing of food processing equipment?

- Steel billets are used in the manufacturing of food processing equipment as they serve as the primary raw material for shaping and forming various components such as frames, supports, blades, and cutting tools. These billets are heated, rolled, and machined into desired shapes and sizes to create durable and robust equipment that can withstand the demanding conditions of food processing operations while ensuring hygiene, safety, and efficiency.

- Q: What are the different types of cutting methods used for steel billets?

- There are several different types of cutting methods used for steel billets, including sawing, shearing, flame cutting, and water jet cutting.

Send your message to us

Grade Q215 super square steel billet form China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17172 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords