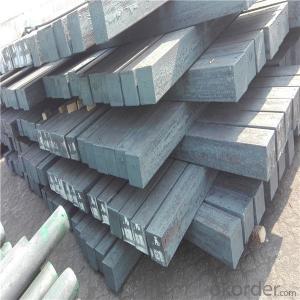

150x150 mm Steel Billet -Q215 Grade factory sale directly

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 18321 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billets have distinct characteristics as compared with already furnished steel bars and products.

Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel

billets are also known for their malleability and ductility, especially when exposed to varying temperatures

during shaping and molding.

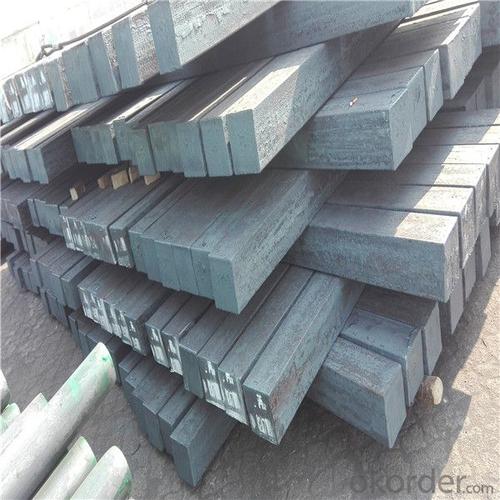

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

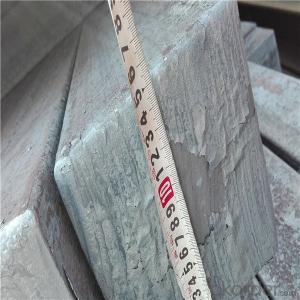

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets used in the production of oil and gas pipelines?

- Steel billets are a crucial component in the production of oil and gas pipelines. They serve as the starting material for the manufacturing process of these pipelines. Steel billets are essentially semi-finished steel products that are often in a rectangular or square shape. To produce oil and gas pipelines, the steel billets undergo a series of manufacturing processes. First, the billets are heated to high temperatures in a furnace. This process, known as billet heating, allows the steel to become more malleable and easier to shape. Once the billets reach the desired temperature, they are then passed through a series of rollers to transform their shape into a cylindrical form. This process is called hot rolling, and it helps to further enhance the mechanical properties of the steel, making it stronger and more durable. After hot rolling, the steel is typically subjected to a process called quenching and tempering. Quenching involves rapidly cooling the steel to increase its hardness, while tempering is a heat treatment process that reduces the brittleness of the steel, making it less prone to cracking. Once the steel billets have been transformed into cylindrical pipes through these processes, they are then welded together to form the final pipeline. Welding ensures the integrity and strength of the pipeline, allowing it to withstand the high pressures and harsh environments associated with the transportation of oil and gas. Overall, steel billets play a vital role in the production of oil and gas pipelines. They serve as the foundation material, undergoing various manufacturing processes to transform them into durable, high-strength pipes that can efficiently transport oil and gas across vast distances.

- Q: What are the different methods of surface treatment for steel billets?

- There are several different methods of surface treatment for steel billets, each serving a specific purpose and offering unique benefits. Some of the most common methods include: 1. Pickling: This process involves immersing the steel billets in an acid solution to remove any surface impurities, such as rust or scale. Pickling helps to improve the surface finish and prepare the steel for further treatment or processing. 2. Shot blasting: In this method, steel billets are bombarded with high-speed steel shots or grits to remove surface contaminants and create a uniform texture. Shot blasting is commonly used to remove rust, scale, or paint, and it can also improve the adhesion of subsequent coatings or paints. 3. Galvanizing: This surface treatment involves coating the steel billets with a layer of zinc to provide corrosion resistance. Galvanizing can be done through hot-dip galvanizing, where the steel is immersed in a molten zinc bath, or through electroplating, where a thin layer of zinc is deposited on the surface using an electric current. 4. Painting or powder coating: Steel billets can be painted or powder coated to provide both aesthetic appeal and protection against corrosion. Paints or powder coatings create a barrier between the steel surface and the environment, preventing moisture and other corrosive agents from reaching the metal. 5. Passivation: This method involves treating the steel billets with a chemical solution, typically an acid, to remove any free iron or iron oxide from the surface. Passivation helps to enhance the corrosion resistance of stainless steel and other alloys by creating a passive oxide layer that protects against further oxidation or rusting. 6. Nitriding: Nitriding is a surface hardening treatment where the steel billets are exposed to a nitrogen-rich atmosphere at elevated temperatures. This process diffuses nitrogen into the surface of the steel, forming a hardened layer that increases wear resistance and improves fatigue strength. 7. Chrome plating: Steel billets can be coated with a layer of chromium through electroplating, providing enhanced corrosion resistance and a shiny appearance. Chrome plating is often used in applications where aesthetics and durability are important, such as automotive parts or decorative fixtures. These are just a few examples of the different methods of surface treatment for steel billets. The choice of method depends on factors such as the desired outcome, the specific properties required, and the intended application of the steel billets.

- Q: What are the main differences between hot rolled and cold rolled steel billets?

- The main differences between hot rolled and cold rolled steel billets lie in the manufacturing process and resulting properties. Hot rolled steel billets are created by heating the steel and then rolling it at high temperatures, which leads to a rougher surface finish and less precise dimensions. On the other hand, cold rolled steel billets undergo a process of rolling at room temperature, resulting in a smoother surface finish and tighter dimensional tolerances. Moreover, hot rolled steel billets are generally more ductile and have a higher carbon content, while cold rolled steel billets are typically harder and have improved strength due to the strain hardening during the cold rolling process.

- Q: How are steel billets stored?

- To safeguard steel billets from corrosion and other harm, they are commonly stored in a controlled environment. The approach to storage varies based on billet size, quantity, and the specific requirements of the steel producer. One frequently employed method involves horizontally stacking the billets on a flat surface, such as a concrete floor or specialized steel racks. The billets are arranged in rows and columns, leaving sufficient space for easy access and inspection. To ward off corrosion, the billets are typically coated with a protective layer, such as oil or rust inhibitors, before being stored. Furthermore, the storage area may be equipped with dehumidifiers or climate control systems to maintain optimal humidity levels and prevent moisture-related damage. For larger quantities, vertical storage in specialized racks or bins is an option. This allows for efficient space utilization and facilitates handling with the aid of machinery like cranes and forklifts. These vertical storage systems are designed to distribute the weight of the billets evenly, thus preventing deformation or damage. Regardless of the chosen storage method, regular inspection is crucial to identify any signs of damage or deterioration, such as rust, cracks, or other defects that may impact the steel's quality. Proper documentation and inventory management are also essential for efficient retrieval and use of the billets. In summary, the storage of steel billets prioritizes their protection and preservation. By adhering to appropriate storage practices, steel manufacturers can uphold the billets' quality and ensure their suitability for subsequent manufacturing processes.

- Q: Are steel billets used in the production of furniture?

- No, steel billets are typically not used in the production of furniture. Steel billets are semi-finished products made from molten iron that are later shaped into various forms, such as bars, rods, or sheets, through a process called hot rolling. While steel may be used in the manufacturing of furniture, it is usually in the form of finished products such as steel tubing, steel sheets, or steel frames. These finished steel products are more commonly used in the construction of furniture, particularly in industrial or modern designs. The use of steel in furniture production provides durability, strength, and a sleek aesthetic. However, the steel used in furniture manufacturing is usually obtained through different processes than the production of steel billets.

- Q: Can steel billets be used for making architectural structures?

- Yes, steel billets can be used for making architectural structures. Steel billets are semi-finished products that are typically cast into specific shapes and sizes before being further processed into different steel products. These billets can be used as a raw material for fabricating various architectural structures such as beams, columns, frames, and trusses. Steel is a widely used material in the construction industry due to its high strength, durability, and versatility. It offers several advantages over other construction materials, including its ability to withstand heavy loads, resist corrosion, and provide excellent fire resistance. Steel billets can be processed and shaped into different forms, allowing architects and engineers to create innovative and complex architectural designs. Furthermore, steel structures offer several benefits in terms of cost-effectiveness, speed of construction, and sustainability. Steel is a highly recyclable material, making it an environmentally friendly choice. The use of steel billets in architectural structures enables the construction of large and complex structures with greater precision and efficiency. Overall, steel billets can be effectively used in the construction of architectural structures, offering numerous advantages in terms of strength, durability, design flexibility, and sustainability.

- Q: Fish pole carbon cloth tcf. Vcf. Svf. Hcf. On behalf of what?

- According to the T value difference, broadly divided into 4 categoriesHCF: for 24T advanced carbon fiber materialSCF: for 30T advanced carbon fiber materialVCF: for 40T~50T premium carbon fiber materialTCF: for 55T~80T top carbon fiber materialHVF, HCF means high carbon fiber, H High (Senior).HVF:High, Volume, Fiber carbon fiber material 30T-40T.HCF:High, Volume, Carbon, Fiber carbon fiber material 24T."SVF" and "SCF" mean "super high carbon fiber", and "H" means "Super"SVF:Super, High, Volume, Carbon, Fiber carbon fiber material 40T-60T.SCF:Super, Volume, Carbon, Fiber carbon fiber material 30T.

- Q: 20 what is the difference between manganese silicon steel billet and Q235 billet?

- 20 manganese silicon steel billet for high strength steel,Q235 billet is almost the most common steel, requiring the lowest.

- Q: Can the production of continuous casting billet be damaged by using intermediate frequency electric furnace?

- If there are no other major facts of harm, it seems that there is no such mandatory legal provisions to bear criminal responsibility. Mandatory closing and fines at most.

- Q: How are steel billets used in the production of flanges?

- Steel billets are an essential raw material used in the production of flanges. Flanges are critical components that connect pipes, valves, and other equipment in various industrial applications, such as oil and gas, petrochemicals, and power plants. To manufacture flanges, steel billets are first heated to a high temperature to make them malleable and easy to shape. They are then passed through a series of rolling mills, where they undergo hot rolling or forging processes. This helps to shape the steel billets into the desired flange dimensions, including outer diameter, inner diameter, and thickness. During the rolling or forging process, the steel billets are subjected to immense pressure, which helps to align the steel grains and improve the structural integrity of the flanges. This ensures that the flanges can withstand high pressures, temperature variations, and other challenging operating conditions that they may encounter during their service life. Once the initial shaping is complete, the flanges are further processed to refine their surface finish. This may involve machining, grinding, or polishing, depending on the specific requirements of the flange design. These additional processes help to achieve a smooth and precise surface, ensuring proper sealing and connection when the flanges are installed in a piping system. After the surface finish is refined, the flanges undergo various quality control checks, including dimensional inspections, mechanical testing, and non-destructive testing. These tests ensure that the flanges meet industry standards and specifications, guaranteeing their reliability and performance. In summary, steel billets are crucial in the production of flanges as they provide the raw material necessary for shaping and forming these essential components. The combination of high-temperature processing, rolling or forging, and subsequent finishing processes helps to create flanges that are strong, durable, and capable of withstanding demanding conditions in industrial applications.

Send your message to us

150x150 mm Steel Billet -Q215 Grade factory sale directly

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 18321 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords