Standard Extruded Aluminum Profiles for Office Screen Office Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Profiles for Office Screen Office Partition

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Profiles for Office Screen Office Partition

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Profiles for Office Screen Office Partition

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

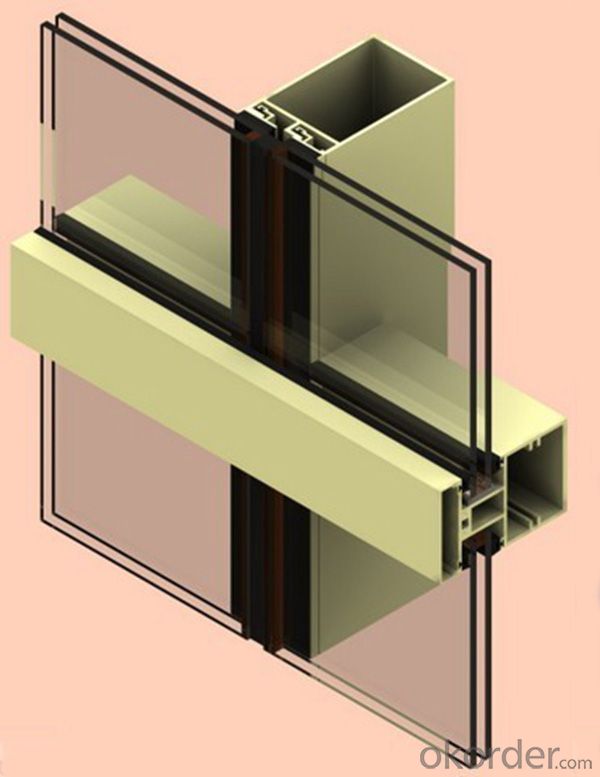

5. Image of Aluminum Profiles for Office Screen Office Partition

6. Package and shipping of Aluminum Profiles for Office Screen Office Partition

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Are aluminum profiles suitable for use in pharmaceutical manufacturing?

- Pharmaceutical manufacturing can benefit greatly from the use of aluminum profiles. These profiles offer a range of advantages in the industry due to the versatile and lightweight nature of aluminum. One crucial advantage is the corrosion resistance of aluminum profiles, which is of utmost importance in pharmaceutical manufacturing where cleanliness and hygiene are vital. Aluminum does not rust or deteriorate when exposed to moisture, making it an ideal material for cleanrooms and sterile environments. Furthermore, aluminum profiles are easy to clean and maintain, maintaining their structural integrity even after rigorous cleaning processes such as sterilization and disinfection. This ensures that the pharmaceutical manufacturing equipment remains in a pristine and contamination-free condition. Customization is another key benefit of aluminum profiles in pharmaceutical manufacturing. These profiles can be easily fabricated into various shapes and sizes, allowing for the creation of complex structures and machinery. This flexibility makes aluminum profiles an excellent choice for designing precise pharmaceutical equipment, including conveyor systems, processing machinery, and packaging equipment. Additionally, aluminum profiles possess excellent thermal conductivity, which is advantageous in pharmaceutical manufacturing processes that involve temperature control. Freeze-drying, sterilization, and granulation, for example, can benefit from efficient heat transfer provided by aluminum profiles. This ensures that pharmaceutical products are processed and stored at the desired temperature. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, reducing the carbon footprint associated with pharmaceutical manufacturing. The ability to reuse and repurpose aluminum profiles contributes to a circular economy and minimizes waste generation. In conclusion, aluminum profiles are highly suitable for pharmaceutical manufacturing. Their corrosion resistance, ease of cleaning, customization options, thermal conductivity, and sustainability make them an excellent choice for designing and fabricating pharmaceutical equipment and machinery.

- Q: Household aluminum profiles, which brand of cost-effective? Recommend!

- Cost performance is better, in our Nanshan factory is called a good fight,

- Q: What are the differences between horizontal and vertical aluminum profiles?

- Vertical jet powder will be better than horizontal, horizontal spray is not good, there will be a zebra crossing

- Q: What are the various materials that can be combined with aluminum profiles in construction or manufacturing?

- <p>Aluminum profiles can be combined with a variety of materials to enhance their functionality and durability. Common materials include steel for added strength, plastics for lightweight components, and various types of glass for transparency and aesthetics. They can also be paired with rubber or silicone seals for weatherproofing, and wood for a warmer, more natural aesthetic. Additionally, aluminum profiles are often used with other metals such as copper or brass for electrical conductivity or corrosion resistance. The choice of material depends on the specific application, desired properties, and design requirements.</p>

- Q: How do you cut aluminum profiles?

- If you need to cut aluminum profiles, there are a variety of methods available to you depending on the tools and equipment at your disposal. Here, we will discuss three commonly utilized techniques: 1. Power Saw: To effectively cut aluminum profiles, a power saw like a miter saw or circular saw equipped with a specialized carbide-tipped blade designed for metal cutting is recommended. Adjust the blade to the appropriate speed and angle for your desired cut, and carefully guide the saw through the profile, ensuring a smooth and precise cut. 2. Hacksaw: If power tools are not accessible, a hacksaw is a cost-effective and readily available alternative. Select a fine-toothed blade designed for cutting metal and securely fix the aluminum profile in a vise or workbench. Employ long, steady strokes to slice through the profile, applying gentle pressure to maintain control and prevent blade binding. 3. Shearing: For thinner aluminum profiles, a manual shear can be employed to make straight cuts. Position the profile in the shear, aligning the cutting edge with the desired cut line, and steadily exert pressure on the handle to allow the shear to effortlessly slice through the aluminum. This method is particularly suitable for cutting thinner profiles with precision and minimal risk of distortion. Regardless of the method you choose, it is crucial to wear appropriate safety gear, such as safety glasses and gloves, to safeguard yourself against metal shavings and sharp edges. Moreover, always accurately measure and mark your cut line before initiating the cutting process to ensure your desired outcome.

- Q: Is it possible to tailor aluminum profiles to fulfill particular design and aesthetic needs?

- <p>Yes, aluminum profiles can be customized to meet specific aesthetic requirements. Manufacturers offer a variety of finishes, colors, and surface treatments to enhance the visual appeal of aluminum profiles. Additionally, the profiles can be cut, bent, and shaped to fit unique design specifications. This customization allows for a high degree of flexibility in creating structures and designs that are both functional and visually appealing, making aluminum profiles suitable for a wide range of applications from architectural to industrial design.</p>

- Q: Are aluminum profiles compatible with other materials for construction purposes?

- <p>Yes, aluminum profiles can be used in combination with other materials in construction. They are often paired with steel, glass, and various plastics due to their lightweight, durability, and corrosion resistance. Aluminum's ability to be easily joined and its compatibility with different finishes make it a versatile choice for construction projects.</p>

- Q: Is it possible to recycle aluminum profiles through the current recycling systems in place?

- <p>Yes, aluminum profiles can be recycled using existing recycling programs. Aluminum is one of the most recycled materials globally due to its non-toxic nature and the energy efficiency of recycling it. Most recycling programs accept aluminum, and aluminum profiles can be collected, sorted, and processed to be melted down and reused in new products. It's important to check with local recycling facilities to understand their specific guidelines and requirements for recycling aluminum profiles.</p>

- Q: Can aluminum profiles be used for access control systems?

- Yes, aluminum profiles can be used for access control systems. Aluminum is a versatile and durable material that is commonly used in construction and various industries. It offers excellent strength-to-weight ratio, corrosion resistance, and can be easily shaped and fabricated. When it comes to access control systems, aluminum profiles can be utilized for the construction of doors, frames, and enclosures. These profiles can be designed to accommodate various components such as locks, hinges, control panels, and readers. The lightweight nature of aluminum makes it suitable for door and frame construction, as it allows for easy installation and maintenance. Additionally, aluminum profiles can be finished with different coatings to enhance their appearance and protect them from harsh environmental conditions. Anodizing, for example, can provide a durable and corrosion-resistant surface that can withstand constant use and exposure to the elements. Furthermore, aluminum profiles can be customized to meet specific design requirements. They can be easily cut, drilled, and assembled, allowing for flexibility in creating access control systems that fit the desired aesthetics and functionality. In summary, aluminum profiles are a suitable choice for access control systems due to their strength, lightweight nature, corrosion resistance, and versatility in design. They offer durability and can be easily customized to meet specific requirements, making them a reliable and practical option for securing access points.

- Q: How do you join two aluminum profiles together?

- To achieve the desired strength, appearance, and functionality of a joint between two aluminum profiles, there are multiple techniques available. Here are a few commonly employed methods: 1. Utilizing Mechanical Fasteners: One straightforward and widely used approach is to employ mechanical fasteners like screws, bolts, or rivets. These fasteners can be drilled through both profiles and tightened to securely connect them. The selection of the appropriate size and type of fastener should be based on the profiles' thickness and material. 2. Employing Welding: Welding is another popular means of joining aluminum profiles. It involves melting the aluminum at the joint and allowing it to solidify, creating a strong bond between the profiles. Different welding techniques, such as TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding, can be utilized depending on the specific application and requirements. 3. Implementing Adhesives: Adhesive bonding provides a non-intrusive method for connecting aluminum profiles. Specially formulated adhesives designed for aluminum bonding can be applied to the profile surfaces and then pressed together. This type of joint is particularly advantageous when a seamless appearance is desired, as it eliminates the need for visible fasteners or welds. However, the strength of the adhesive bond may vary depending on the adhesive type. 4. Employing Interlocking Systems: Certain aluminum profiles are designed with interlocking systems that allow for easy connection. These systems typically involve the use of connectors or accessories specifically designed for the given profiles. They can deliver a secure and sturdy joint while also simplifying the assembly process. When choosing the appropriate method to join two aluminum profiles, it is vital to consider factors such as strength requirements, aesthetics, ease of assembly, and the potential need for disassembly. Additionally, consulting professionals or experts in aluminum fabrication is recommended to ensure the chosen method suits the specific application.

Send your message to us

Standard Extruded Aluminum Profiles for Office Screen Office Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords