10mm Aluminum Profiles According to the Standard American

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profiles Acoording to The Standard AmericanDescription:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profiles Acoording to The Standard American:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

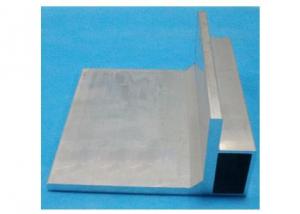

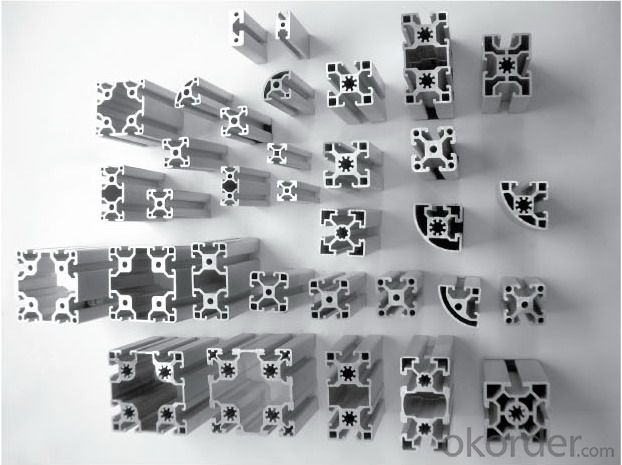

Images of the Aluminium Profiles Acoording to The Standard American:

Aluminium Profiles Acoording to The Standard American Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Profiles Acoording to The Standard American:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Request recommended professional aluminum manufacturer?

- Jing Long aluminum, aluminum strip and aluminum wafer production capacity of 60000 tons, this piece in Shangqiu, still have the strength, is a professional production and processing, wholesale distribution of aluminum, hot-rolled plate, hot rolled plate, aluminum plate, aluminum plate, roll spindle is the main.

- Q: Can aluminum profiles be used for lighting fixtures or systems?

- Lighting fixtures or systems can utilize aluminum profiles. Aluminum, a lightweight and versatile material, is often chosen for constructing lighting fixtures because of its durability, resistance to corrosion, and ability to dissipate heat. Aluminum profiles can be easily shaped and sized, making them suitable for various lighting applications like recessed lighting, track lighting, pendant lighting, and more. Moreover, these profiles can be anodized or coated with different finishes to improve their visual appeal and shield them from the elements. In conclusion, incorporating aluminum profiles in lighting fixtures or systems enables efficient and effective lighting solutions while maintaining a sleek and contemporary design.

- Q: Is the aluminum profile insulated and broken hot?

- Yes, the name is not the same, the professional name is "broken hot aluminum alloy", most people used to call "broken bridge aluminum"

- Q: How do aluminum profiles contribute to energy-saving initiatives?

- Aluminum profiles contribute to energy-saving initiatives in several ways. Firstly, aluminum is a lightweight and durable material, making it an ideal choice for constructing energy-efficient buildings and structures. The use of aluminum profiles in windows and doors helps to improve insulation and reduce heat transfer, thereby reducing energy consumption for heating and cooling. Additionally, aluminum profiles are often used in the manufacturing of solar panels, as their lightweight nature allows for easier installation and transportation. This promotes the use of renewable energy sources and reduces reliance on fossil fuels. Overall, aluminum profiles play a significant role in enhancing energy efficiency and promoting sustainability in various industries.

- Q: How can I distinguish aluminum from aluminium oxide or electrophoresis aluminum or spray aluminium material?

- The electrophoretic material looks very textured, very uniform, and full range. Spray paint will not spray in some places, and the color is not as good as electrophoresis.

- Q: This question asks if it is possible to recycle aluminum profiles in a simple and effective manner.

- <p>Yes, aluminum profiles can be recycled easily and efficiently. Aluminum is one of the most recycled materials in the world due to its non-toxic nature and the energy efficiency of the recycling process. Recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it a highly sustainable material. The recycling process involves melting the aluminum, which is a relatively simple and cost-effective procedure compared to many other materials. This makes aluminum an ideal material for sustainable manufacturing and waste reduction strategies.</p>

- Q: Is it possible to tailor aluminum profiles to fulfill particular design and aesthetic needs?

- <p>Yes, aluminum profiles can be customized to meet specific aesthetic requirements. Manufacturers offer a variety of finishes, colors, and surface treatments to enhance the visual appeal of aluminum profiles. Additionally, the profiles can be cut, bent, and shaped to fit unique design specifications. This customization allows for a high degree of flexibility in creating structures and designs that are both functional and visually appealing, making aluminum profiles suitable for a wide range of applications from architectural to industrial design.</p>

- Q: Features of aluminum profiles

- Thermal conductivityThe thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and the cylinder head and radiator of automobiles.FerromagnetismAluminum is non ferromagnetic, which is an important feature of the electrical and electronic industries. Aluminum can not be spontaneous combustion, which is involved in loading and unloading or exposure to flammable and explosive materials is important.

- Q: Can aluminum profiles be used for staircases and handrails?

- Yes, aluminum profiles can be used for staircases and handrails. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for these applications. Additionally, aluminum profiles offer versatility in terms of design options and can be easily customized to suit specific requirements.

- Q: How to distinguish the good or bad of aluminum profile simply?

- Then, how to distinguish the aluminum profile is good or bad? Let's get to know those aluminum profiles that are not qualified.First, extrusion defects.Aluminum extrusion process for machine equipment is perfect, process technology is mature and whether the operation staff misconduct and other reasons, will lead to aluminum flakes, such as inclusion, delamination, chromatic aberration, distortion and other defects, affecting the quality of aluminum profiles.Second, the film thickness is thin.Industrial aluminum oxide film thickness standard should be not less than 10um (m). If the thickness is not enough, the surface of the aluminum profile is easy to rust and corrode and shorten the service life. In order to save the cost, the thickness of the oxide film is only 2 to 4um, and some even have no oxide film. It is estimated that each reduction of 1um film thickness can reduce power consumption by more than 150 yuan per ton.

Send your message to us

10mm Aluminum Profiles According to the Standard American

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords