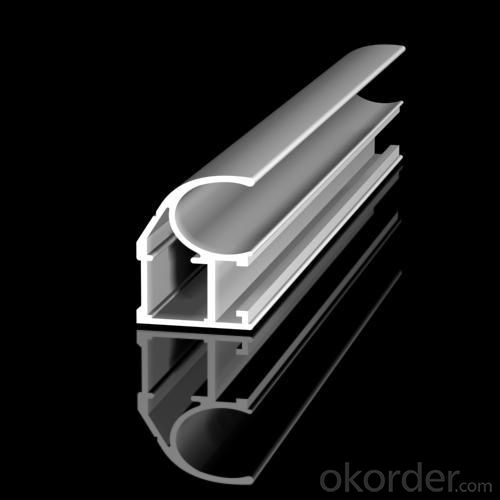

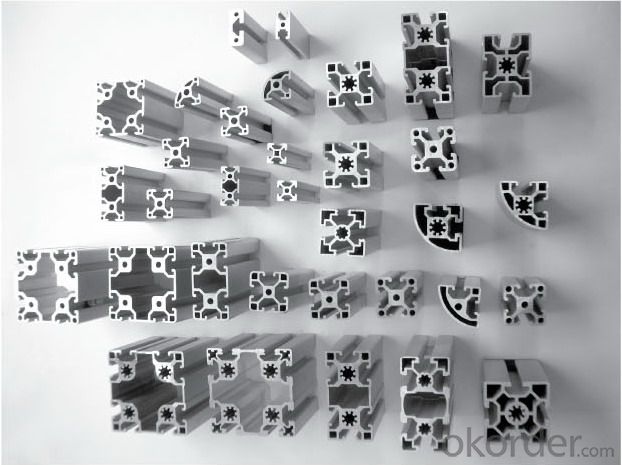

Aluminum Extrusion Profiles for 100mm Double Glass/Wood Office Partitions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminum Profiles 100mm Double Glass/Wood Office Partitions Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminum Profiles 100mm Double Glass/Wood Office Partitions:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Aluminum Profiles 100mm Double Glass/Wood Office Partitions:

Aluminum Profiles 100mm Double Glass/Wood Office Partitions Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Can aluminum profiles be used in the production of signage?

- Yes, aluminum profiles can be used in the production of signage. Aluminum profiles are popular in the signage industry due to their durability, versatility, and aesthetic appeal. They can be easily shaped and cut into various sizes and designs, making them suitable for different types of signage such as indoor and outdoor signs, lightboxes, channel letters, and more. Aluminum profiles are also lightweight, corrosion-resistant, and weatherproof, allowing them to withstand harsh environmental conditions and ensure long-lasting signage. Additionally, aluminum profiles can be easily painted, powder-coated, or anodized in different colors, providing endless design possibilities for signage projects. Overall, using aluminum profiles in signage production offers numerous advantages in terms of durability, customization, and visual appeal.

- Q: Can aluminum profiles be used in electrical panel manufacturing?

- Yes, aluminum profiles can be used in electrical panel manufacturing. Aluminum is a lightweight and durable material that offers excellent electrical conductivity, making it suitable for use in electrical panels. It also has good heat dissipation properties, which is important for preventing overheating in electrical systems. Aluminum profiles can be easily fabricated and customized to meet the specific requirements of electrical panel designs. Additionally, aluminum is resistant to corrosion, which ensures the longevity of the electrical panel. Overall, aluminum profiles are a popular choice in electrical panel manufacturing due to their numerous benefits.

- Q: What are the different surface texturing options for aluminum profiles?

- There are several surface texturing options available for aluminum profiles, each offering unique benefits and aesthetic appeal. Some of the common surface texturing options for aluminum profiles include: 1. Brushing or Satin Finishing: This technique involves the use of abrasive brushes to create a linear or circular pattern on the surface of the aluminum profile. It provides a smooth, matte finish, which is visually appealing and hides minor imperfections. 2. Anodizing: Anodizing is a popular surface treatment method that involves creating an oxide layer on the aluminum surface. This process not only enhances the corrosion resistance of the profile but also allows for the application of various colors, making it an excellent choice for decorative applications. 3. Polishing: Polishing is a process that involves mechanically smoothing the surface of the aluminum profile to achieve a reflective finish. This technique is commonly used in architectural applications where a high-gloss appearance is desired. 4. Powder Coating: Powder coating is a durable and versatile surface treatment option for aluminum profiles. A dry powder is electrostatically applied to the profile, and then it is cured under heat, creating a protective and decorative coating. Powder coating provides a wide range of color options and excellent resistance to weathering, making it suitable for both interior and exterior applications. 5. Textured Coating: Textured coating is a specialized powder coating technique that offers a unique texture and appearance to the aluminum profile. It can mimic various textures, such as wood grain or stone, adding a distinctive look to the profile. 6. Chemical Etching: Chemical etching is a process that involves selectively removing material from the surface of the aluminum profile using chemical solutions. This technique can create intricate patterns or designs on the surface, making it ideal for decorative or branding purposes. 7. Laser Engraving: Laser engraving is a precise and versatile method for creating patterns, logos, or text on the surface of aluminum profiles. The laser beam removes the material, leaving a permanent mark on the profile. Laser engraving offers high precision and customization options, making it suitable for branding and personalization. These are just a few examples of the surface texturing options available for aluminum profiles. The choice of texturing method depends on the desired appearance, functionality, and application of the profile.

- Q: Are there any specific safety precautions when working with aluminum profiles?

- Yes, there are specific safety precautions to consider when working with aluminum profiles. Here are some key precautions to follow: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE such as safety glasses, gloves, and protective clothing to protect yourself from potential injuries. Aluminum chips or shavings can be sharp and may cause cuts or abrasions. 2. Ventilation: Ensure good ventilation in the working area to prevent the accumulation of aluminum dust or fumes. Aluminum dust can be combustible, and inhaling aluminum fumes can lead to health issues, including respiratory problems. 3. Fire Safety: Aluminum is highly flammable, so it is crucial to have fire prevention measures in place. Keep a fire extinguisher nearby and avoid sparks or open flames near aluminum profiles. Use non-sparking tools and avoid excessive heat during cutting or welding processes. 4. Handling and Storage: Aluminum profiles can be heavy, so use proper lifting techniques to prevent back or muscle injuries. Store aluminum profiles in a secure and organized manner to avoid the risk of tripping or falling. 5. Cutting and Machining: When cutting or machining aluminum profiles, use appropriate tools and techniques. Ensure the material is securely clamped before any cutting operation to prevent movement and potential accidents. 6. Ergonomics: Maintain good ergonomics while working with aluminum profiles to minimize the risk of repetitive strain injuries or musculoskeletal disorders. Use ergonomic tools or equipment to reduce strain on your body. 7. Training and Knowledge: It is essential to have proper training and knowledge about working with aluminum profiles. Understand the specific properties of aluminum and the associated hazards to work safely and effectively. By following these safety precautions, you can significantly reduce the risk of accidents, injuries, or health hazards when working with aluminum profiles.

- Q: Are there any differences between aluminum alloy and aluminum alloy?

- Aluminum alloy refers to the material, aluminum alloy refers to the productIt's like the difference between gold and gold

- Q: This question asks for an overview of the various types of connectors that are used to join aluminum profiles in construction or assembly.

- <p>Aluminum profiles are joined together using several types of connectors, each serving specific purposes in assembly. Common types include: 1. T-slots and T-nuts, which provide a secure and adjustable connection. 2. Corner brackets, used to join profiles at right angles. 3. Angle connectors, for joining profiles at various angles. 4. End caps, used to cover the ends of profiles. 5. Clamps and brackets, for securing profiles in place. 6. Hinges, allowing for pivoting connections. 7. Cylindrical connectors, for joining round profiles. 8. Specialized connectors for specific applications, such as cable management or modular systems. These connectors are crucial for creating robust, modular structures in various industries.</p>

- Q: Are aluminum profiles suitable for use in automotive body structures?

- Yes, aluminum profiles are suitable for use in automotive body structures. Aluminum is a lightweight and durable material that offers several advantages in the automotive industry. Its high strength-to-weight ratio makes it an ideal choice for constructing body frames, panels, and other structural components. Using aluminum profiles in automotive body structures offers benefits such as improved fuel efficiency, as the lighter weight of the material reduces the overall weight of the vehicle. This, in turn, allows for better acceleration and handling. Additionally, aluminum possesses excellent corrosion resistance, which is crucial for withstanding harsh environmental conditions and extending the lifespan of the vehicle. Furthermore, aluminum profiles can be easily shaped and formed into complex designs, allowing for greater design flexibility in automotive body structures. This versatility enables manufacturers to create more aerodynamic and visually appealing vehicles. While aluminum profiles offer numerous advantages, there are also some considerations to be aware of. Aluminum can be more expensive than traditional steel, which may impact the overall cost of the vehicle. Additionally, the repair and maintenance of aluminum structures may require specialized equipment and expertise. However, these factors are outweighed by the benefits aluminum profiles bring to the automotive industry. In conclusion, aluminum profiles are indeed suitable for use in automotive body structures. Their lightweight, durable, and corrosion-resistant properties, along with their design flexibility, make them an excellent choice for constructing modern vehicles.

- Q: This question asks if aluminum profiles can be utilized in sustainable construction projects and seeks an explanation of their application.

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their durability, recyclability, and energy efficiency. Aluminum profiles are lightweight, which reduces the load on structures and can contribute to energy savings in heating and cooling. They also have high thermal conductivity, which can be beneficial for heat transfer in building systems. Additionally, aluminum is 100% recyclable, meaning it can be repurposed without losing its properties, reducing waste and the need for new raw materials. This recyclability aligns with the principles of sustainable construction by promoting a circular economy and reducing the environmental impact of building materials.</p>

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: The number of aluminum profiles can be meters or KG. How exactly is it? How do you understand that?

- You see the amount of it, if it is aluminum ingot is certainly in tons to calculate, the profile is, if it is a fixed size, usually 6 meters long.

Send your message to us

Aluminum Extrusion Profiles for 100mm Double Glass/Wood Office Partitions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords