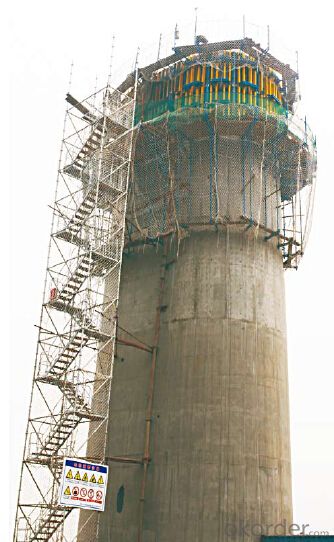

Stair tower for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used in areas with limited access or space constraints?

- Yes, steel formwork can be used in areas with limited access or space constraints. Steel formwork is known for its versatility and adaptability, making it suitable for use in various construction projects, including those with restricted access or limited space. Steel formwork can be easily customized and fabricated to fit specific dimensions and shapes required for a particular project. This flexibility allows construction teams to efficiently work in areas with limited access or space constraints, such as narrow alleys, confined construction sites, or high-rise buildings. Additionally, steel formwork offers high strength and durability, which is crucial when working in challenging environments. It can withstand heavy loads and provide stability to the concrete structure, ensuring safety and structural integrity. Moreover, steel formwork can be quickly assembled and disassembled, enabling easy transportation and installation in areas with restricted access. Its lightweight nature allows for ease of handling and maneuverability, minimizing the requirement for heavy machinery or equipment. In conclusion, steel formwork is a suitable choice for areas with limited access or space constraints due to its adaptability, strength, durability, and ease of assembly. It allows construction teams to efficiently work in challenging environments, ensuring the successful completion of construction projects.

- Q: How does steel formwork contribute to the overall durability of the structure?

- The construction industry relies on steel formwork as a crucial element that greatly enhances the durability of structures. This is primarily due to the inherent strength and durability of steel itself. Steel formwork is crafted from high-quality steel, renowned for its exceptional strength and resilience. The sturdiness of steel formwork enables it to withstand the immense pressure exerted by concrete during the pouring and curing processes. This is especially important for large-scale structures, where the load of concrete can be substantial. Steel formwork provides essential support to ensure that the concrete maintains its shape and form, preventing any deformations or cracks from occurring. Additionally, steel formwork exhibits high resistance to corrosion, a significant concern for construction materials exposed to moisture and environmental factors. This resistance to corrosion ensures that the formwork remains intact and retains its strength over time, even in harsh conditions. By preventing corrosion, steel formwork safeguards the structural integrity of the concrete by avoiding any potential damage caused by rusting or deterioration. Furthermore, steel formwork is known for its reusability, setting it apart from traditional timber formwork. Unlike timber formwork, steel formwork can be used multiple times, reducing the need for constant replacement. This not only saves costs but also minimizes waste and promotes sustainable construction practices. The ability to reuse steel formwork guarantees that the structural elements of a building remain consistently strong and durable throughout the entire construction process. Moreover, steel formwork provides a smooth surface finish to the concrete, enhancing the overall aesthetics of the structure. This smooth finish reduces the necessity for additional surface treatments, saving time and resources during construction. Additionally, it improves the durability of the structure by minimizing the risk of cracks and imperfections, which can compromise the overall integrity of the construction. In conclusion, steel formwork plays a vital role in enhancing the overall durability of structures due to its strength, corrosion resistance, reusability, and ability to provide a smooth surface finish. By providing reliable support during concrete pouring, maintaining its structural integrity over time, and enhancing the aesthetics of the building, steel formwork ensures that the structure remains durable and resilient for years to come.

- Q: How does steel formwork prevent concrete mixture separation during pouring?

- Steel formwork is used in construction projects to provide a temporary structure that holds the concrete in place until it sets and hardens. One of the key benefits of using steel formwork is that it prevents the concrete mixture from separating during the pouring process. The steel formwork is carefully designed and constructed to create a tight enclosure for the concrete, ensuring that it remains in its desired shape and consistency. It is made up of steel panels and frames that are securely fastened together to create a rigid structure. When the concrete mixture is poured into the steel formwork, it is held in place by the walls of the formwork itself. The steel panels and frames provide a smooth and even surface for the concrete to be poured onto, preventing any separation or segregation of the mixture. Furthermore, the steel formwork is designed with properly aligned joints and connections, which further helps in preventing any leakage or seepage of the concrete mixture. This ensures that the concrete remains intact and does not separate into its constituent materials such as aggregates, cement, and water. Additionally, the steel formwork is capable of withstanding the pressure exerted by the weight of the concrete. This prevents any deformation or movement of the formwork during the pouring process, which could potentially cause the concrete to separate or shift. Overall, the use of steel formwork provides a strong and stable structure that prevents the concrete mixture from separating during pouring. It ensures that the concrete remains in its desired form and consistency, resulting in a high-quality and durable finished product.

- Q: Can steel formwork be reused?

- Yes, steel formwork can be reused. Steel formwork is a durable and robust material that can withstand multiple uses. It offers a longer lifespan compared to other types of formwork materials such as timber or plywood. One of the main advantages of using steel formwork is its ability to be easily dismantled and reassembled. This allows for the formwork to be reused on different construction projects, reducing the need for new materials and saving costs. Furthermore, steel formwork is resistant to weather conditions and moisture, which contributes to its longevity. It can withstand the pressure exerted by concrete during pouring and curing without warping or deforming, ensuring a consistent and high-quality finish. Additionally, steel formwork can be easily cleaned and maintained, making it suitable for reuse. After each use, the formwork can be cleaned and inspected to ensure it is in good condition for the next project. Any necessary repairs or replacements can be made to ensure its structural integrity. In summary, steel formwork can be reused due to its durability, strength, resistance to weather conditions, and ease of maintenance. Reusing steel formwork not only saves costs but also contributes to sustainable construction practices by reducing waste and conserving resources.

- Q: What is the maximum height that steel formwork can be used for?

- The maximum height that steel formwork can be used for depends on several factors such as the structural design and engineering requirements of the construction project, the type of steel formwork being used, and the specific conditions of the site. Steel formwork is known for its high strength and durability, making it suitable for constructing tall structures. However, it is important to consider the weight and stability of the formwork system as it increases in height. In general, steel formwork can be used for constructing structures of varying heights, ranging from low-rise buildings to high-rise skyscrapers. The maximum height will often be determined by engineering calculations and considerations, including the weight-bearing capacity of the formwork system, the lateral stability requirements, and the ability to withstand external forces such as wind loads. For taller structures, additional support mechanisms and reinforcement may be required to ensure the stability and integrity of the formwork system. These may include the use of braces, tie rods, and other structural elements to prevent deflection and maintain the desired shape of the concrete during the pouring and curing process. It is crucial to consult with experienced structural engineers and formwork specialists to assess the specific requirements and limitations of each construction project. They will be able to determine the maximum height that steel formwork can be safely used for, taking into account all relevant factors and ensuring the structural integrity and safety of the construction process.

- Q: What are the different types of steel formwork systems?

- Construction projects commonly utilize various types of steel formwork systems, which serve as temporary structures or molds to support concrete during pouring and curing. Below are several types of steel formwork systems commonly used: 1. Traditional steel formwork: This prevalent system involves connecting individual steel panels using clamps or pins. These panels can be adjusted to create different shapes and sizes, and they are straightforward to assemble and disassemble. 2. Modular steel formwork: This system relies on prefabricated steel modules that are interconnected to form larger formwork assemblies. The modules are lightweight and easy to handle, making them ideal for repetitive use in projects with consistent shapes and sizes. 3. Tunnel formwork: Specifically designed for tunnel or underground structure construction, this system utilizes interconnected steel panels to create a seamless, continuous mold. It is commonly employed in large-scale infrastructure projects like subway systems or underground parking garages. 4. Climbing formwork: This system is suitable for tall structures such as high-rise buildings or towers. It comprises vertically extendable steel formwork panels that are attached to a climbing mechanism. This mechanism facilitates lifting and repositioning of the panels at each level, enabling uninterrupted construction. 5. Slip formwork: For vertical structures like walls or columns, slip formwork is utilized. It involves a moving formwork that is continuously filled with concrete as it ascends. Steel rods or cables support the formwork, allowing for the swift construction of tall and straight structures. These examples represent only a portion of the diverse steel formwork systems available. The selection of the most suitable system depends on the project's specific requirements, including structure size, shape, complexity, desired construction speed, and cost-effectiveness.

- Q: Can steel formwork be used for school construction projects?

- Yes, steel formwork can be used for school construction projects. Steel formwork is a durable and versatile construction material that can withstand the heavy loads and pressures encountered in school buildings. It provides a strong and stable framework for concrete pouring, ensuring the structural integrity of the construction. Additionally, steel formwork is reusable, which makes it a cost-effective choice for school construction projects. Its adaptability allows for the creation of various shapes and sizes, catering to the unique architectural designs often seen in school buildings. Furthermore, steel formwork offers faster construction times compared to traditional timber formwork, allowing for quicker completion of school projects. Overall, steel formwork is a suitable and reliable choice for school construction projects.

- Q: How does steel formwork accommodate for different concrete pouring rates?

- Steel formwork can accommodate different concrete pouring rates by its ability to withstand high pressures exerted by the concrete. The strength and rigidity of steel allow it to contain and support the concrete, regardless of the speed at which it is poured. This ensures that the formwork remains stable and intact, preventing any deformations or collapses during the pouring process.

- Q: How does steel formwork compare to timber formwork in terms of cost?

- Compared to timber formwork, steel formwork tends to have higher upfront costs. This is mainly because steel is more expensive than timber. In addition, steel formwork often requires specialized equipment and skilled labor for assembly and disassembly, which can increase the overall cost. However, it is crucial to consider the long-term advantages and cost-effectiveness of steel formwork. Although timber formwork may have a lower initial cost, it is more prone to damage, especially in harsh weather conditions or with repeated use. On the other hand, steel formwork is highly durable and can be used for multiple construction projects, making it a cost-effective choice in the long run. Furthermore, steel formwork provides greater precision and accuracy, resulting in better quality finishes and less rework. It also allows for faster construction due to its easy assembly and disassembly, which can lead to significant time and labor savings, ultimately offsetting the higher upfront cost. To summarize, although steel formwork may be initially more expensive, it offers durability, reusability, and increased productivity, making it a more cost-effective option in the long term compared to timber formwork.

- Q: How does steel formwork affect the overall acoustic properties of the structure?

- Steel formwork does not significantly affect the overall acoustic properties of a structure. Steel formwork refers to temporary structures made of steel panels that are used to hold concrete in place during the construction process. These formwork systems are usually removed once the concrete has hardened. The acoustic properties of a structure are primarily determined by the materials used in the permanent construction elements, such as walls, floors, and ceilings. Steel formwork is not a permanent part of the structure and does not contribute to its acoustic properties. However, it is important to note that during the construction process, steel formwork can create temporary noise and vibrations due to the handling of the steel panels, as well as the pouring and compacting of concrete. These construction activities can generate noise that may impact the acoustic environment in the immediate vicinity of the construction site. However, once the formwork is removed and the structure is completed, the steel formwork itself does not have a significant impact on the overall acoustic properties of the building.

Send your message to us

Stair tower for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords