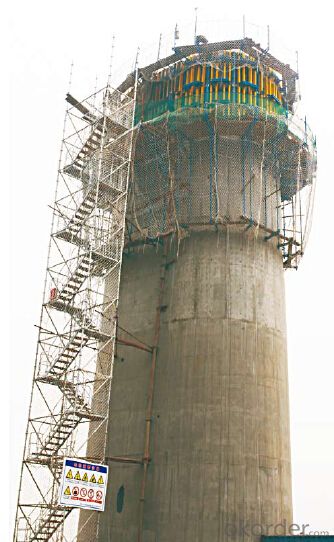

Stair-Tower for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: What are the considerations when designing steel formwork for slabs?

- When designing steel formwork for slabs, there are several important considerations that need to be taken into account. Firstly, the load capacity of the formwork needs to be determined. This involves calculating the total weight of the fresh concrete, reinforcement, and any additional loads such as construction equipment or workers. The strength and stability of the steel formwork must be able to support these loads without any deformation or failure. Another consideration is the size and shape of the slab. The formwork needs to be designed to accurately replicate the desired dimensions and contours of the slab. This may involve creating custom formwork components or using adjustable formwork systems to accommodate variations in slab design. The formwork system also needs to be designed in a way that allows for easy installation and removal. This includes considering the assembly and disassembly process, as well as the handling and transportation of the formwork components. The formwork should be designed to be efficient and time-saving, while also ensuring worker safety during installation and removal. Additionally, the formwork needs to be designed to provide a smooth and even surface finish on the slab. This may involve incorporating appropriate form liners or surface treatments to achieve the desired aesthetic outcome. The formwork should also be designed to prevent any leakage of fresh concrete, as this can result in defects or imperfections on the slab surface. Finally, the durability and reusability of the formwork need to be considered. Steel formwork is often chosen for its strength and longevity, but it is important to ensure that the formwork can withstand repeated use without any significant deterioration or damage. Proper maintenance and storage practices should also be implemented to extend the lifespan of the formwork. In conclusion, designing steel formwork for slabs requires careful consideration of load capacity, slab size and shape, installation and removal processes, surface finish requirements, and durability. These considerations are essential to ensure a successful and efficient construction process while meeting the desired quality standards for the slab.

- Q: What are the common design considerations for steel formwork systems?

- Some common design considerations for steel formwork systems include the load capacity of the system, the stability and rigidity of the forms, the ease of assembly and disassembly, the ability to accommodate various concrete shapes and sizes, the durability and longevity of the materials, and the compatibility with other construction methods or systems. Additionally, factors such as cost, availability, and environmental impact may also be taken into account when choosing a steel formwork system.

- Q: How does steel formwork accommodate for different concrete curing temperatures?

- Steel formwork is able to accommodate for different concrete curing temperatures due to its high thermal conductivity. This means that the steel transfers heat more efficiently, allowing for a faster and more uniform distribution of heat throughout the formwork. As a result, the concrete cures at a more consistent temperature, reducing the risk of uneven curing and potential structural issues. Additionally, steel formwork provides better insulation, preventing excessive heat loss or gain during the curing process, which further helps to maintain the desired temperature conditions.

- Q: What are the different sustainability aspects of using steel formwork?

- There are several sustainability aspects associated with the use of steel formwork in construction projects. First and foremost, steel is a highly durable material that can withstand heavy loads and extreme weather conditions. This means that steel formwork can be reused multiple times, reducing the need for frequent replacements and minimizing waste generation. Additionally, steel formwork is resistant to warping, shrinking, and expanding, ensuring consistent and accurate dimensions in the construction process. Another important sustainability aspect of steel formwork is its high strength-to-weight ratio. Compared to other formwork materials, such as wood or plastic, steel is much lighter while still maintaining its structural integrity. This reduces the amount of energy required for transportation and handling, thereby decreasing carbon emissions and fuel consumption. Furthermore, steel is a recyclable material. At the end of its lifespan, steel formwork can be easily dismantled and sent to recycling facilities where it can be melted down and reused to manufacture new steel products. This helps to conserve natural resources and reduce the demand for virgin materials. Moreover, steel formwork offers significant time and cost savings. Its reusability eliminates the need for constant purchases of new formwork materials, reducing construction expenses. Additionally, the ease of assembly and disassembly speeds up the construction process, resulting in shorter project durations and reduced energy consumption. Lastly, steel formwork provides a smooth and uniform surface finish, reducing the need for additional finishing materials such as plaster or paint. This reduces material consumption and waste generation, contributing to a more sustainable construction process. In conclusion, the use of steel formwork in construction projects offers various sustainability benefits, including durability, reusability, recyclability, energy efficiency, cost savings, and reduced material consumption.

- Q: What are the different types of steel formwork systems?

- Construction projects commonly utilize various types of steel formwork systems, which serve as temporary structures or molds to support concrete during pouring and curing. Below are several types of steel formwork systems commonly used: 1. Traditional steel formwork: This prevalent system involves connecting individual steel panels using clamps or pins. These panels can be adjusted to create different shapes and sizes, and they are straightforward to assemble and disassemble. 2. Modular steel formwork: This system relies on prefabricated steel modules that are interconnected to form larger formwork assemblies. The modules are lightweight and easy to handle, making them ideal for repetitive use in projects with consistent shapes and sizes. 3. Tunnel formwork: Specifically designed for tunnel or underground structure construction, this system utilizes interconnected steel panels to create a seamless, continuous mold. It is commonly employed in large-scale infrastructure projects like subway systems or underground parking garages. 4. Climbing formwork: This system is suitable for tall structures such as high-rise buildings or towers. It comprises vertically extendable steel formwork panels that are attached to a climbing mechanism. This mechanism facilitates lifting and repositioning of the panels at each level, enabling uninterrupted construction. 5. Slip formwork: For vertical structures like walls or columns, slip formwork is utilized. It involves a moving formwork that is continuously filled with concrete as it ascends. Steel rods or cables support the formwork, allowing for the swift construction of tall and straight structures. These examples represent only a portion of the diverse steel formwork systems available. The selection of the most suitable system depends on the project's specific requirements, including structure size, shape, complexity, desired construction speed, and cost-effectiveness.

- Q: How does steel formwork affect the construction timeline?

- Steel formwork can have a significant impact on the construction timeline in both positive and negative ways. One of the main advantages of using steel formwork is its durability and strength. Unlike traditional wooden formwork, steel formwork can withstand multiple uses without losing its structural integrity. This means that it can be reused many times, reducing the time and effort required to set up formwork for subsequent construction phases. Additionally, steel formwork allows for faster assembly and disassembly, which can help to expedite construction timelines. Furthermore, steel formwork provides a high level of accuracy and consistency in shaping concrete structures. The precise dimensions and smooth finish achieved with steel formwork ensure that the construction process proceeds smoothly without any delays caused by rework or adjustments. This can lead to faster completion of construction projects. On the other hand, steel formwork can also introduce certain challenges that may affect the construction timeline. Firstly, steel formwork is generally heavier and requires more effort to transport and handle compared to other types of formwork. This may slow down the overall construction process, especially if there are limitations in terms of available equipment or labor. Additionally, steel formwork may require additional time for installation and dismantling compared to other formwork systems. The complexity of steel formwork systems and the need for skilled workers to handle them can result in a longer setup and removal time. This can impact the overall construction timeline, particularly when tight deadlines need to be met. In conclusion, steel formwork can have both positive and negative effects on the construction timeline. Its durability, reusability, and accuracy can help expedite the construction process. However, the weight and complexity of steel formwork may introduce additional challenges that can potentially slow down the construction timeline.

- Q: Can steel formwork be used for swimming pool construction?

- Swimming pool construction can utilize steel formwork, which is a versatile and durable choice commonly employed in the construction industry for various purposes. Steel formwork offers numerous benefits, such as high strength, stability, and reusability, making it ideal for constructing swimming pool walls, floors, and other structures. By employing steel formwork, a smooth and precise finish is achieved, ensuring uniformity in the appearance of swimming pool walls and floors. It can withstand the water pressure, ensuring the structural integrity of the pool. Furthermore, steel formwork is easily assembled and disassembled, facilitating efficient construction and maintenance. Additionally, steel formwork is highly adaptable and can be customized to meet specific design requirements. It accommodates the construction of various shapes and sizes of swimming pools, including both in-ground and above-ground options. This adaptability makes steel formwork the preferred choice for swimming pool construction projects. Nevertheless, when employing steel formwork for swimming pool construction, certain factors must be considered. Proper waterproofing measures must be implemented to prevent water leakage and corrosion of the steel. Adequate reinforcement and support are also necessary to ensure the stability and durability of the pool structure. In conclusion, steel formwork is a suitable option for swimming pool construction due to its strength, durability, and versatility. Proper usage, in combination with appropriate waterproofing and reinforcement measures, can result in a robust and visually pleasing swimming pool.

- Q: Can steel formwork be used for both cast-in-place and precast concrete construction?

- Yes, steel formwork can be used for both cast-in-place and precast concrete construction. Steel formwork is versatile and durable, making it suitable for various construction methods. It can be easily assembled and disassembled, allowing for efficient use in both cast-in-place and precast concrete projects.

- Q: How does steel formwork affect the overall waterproofing of a building?

- Steel formwork does not directly affect the overall waterproofing of a building as it is primarily used for creating the temporary structure that holds wet concrete in place until it hardens. The purpose of steel formwork is to provide stability and shape to the concrete during the construction process. The waterproofing of a building is typically achieved through other means, such as the use of waterproof membranes, sealants, or coatings applied to the external surfaces of the structure. These materials are specifically designed to prevent the passage of water through the building envelope and protect the interior from moisture infiltration. While steel formwork itself may not impact waterproofing, it is essential to ensure proper installation and sealing of the formwork joints to prevent water leakage during the concrete pouring process. Any gaps or cracks in the formwork can lead to water seeping into the structure, potentially compromising the waterproofing system. Moreover, the choice of formwork material can indirectly influence the overall waterproofing of a building. Steel formwork, being a durable and robust material, can withstand the pressure exerted by wet concrete without deforming or leaking. This ensures that the concrete is properly shaped and compacted, leading to a more solid and stable structure. A well-constructed concrete framework, in turn, enhances the overall integrity and longevity of the building, indirectly contributing to its waterproofing capabilities. In summary, while steel formwork does not directly impact the overall waterproofing of a building, it plays a crucial role in ensuring the structural integrity of the concrete during construction. Proper installation and sealing of the formwork joints are essential to prevent water leakage. Ultimately, it is the choice of appropriate waterproofing materials and their correct application that determines the building's overall waterproofing performance.

- Q: How does steel formwork handle architectural features such as openings and recesses?

- Steel formwork is a highly versatile and customizable solution that can easily handle architectural features such as openings and recesses. With its strength and flexibility, steel formwork can be shaped and adjusted to accommodate various shapes and dimensions, ensuring a precise fit. This allows for the creation of openings, recesses, or any other architectural feature required in the construction process. Additionally, steel formwork can be easily dismantled and reused, making it a cost-effective and efficient choice for handling complex architectural designs.

Send your message to us

Stair-Tower for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords