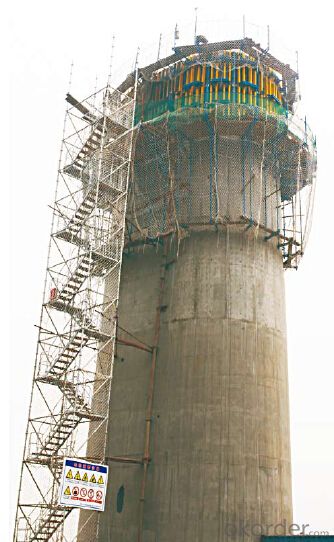

Stair Tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used for both small-scale and large-scale construction projects?

- Yes, steel formwork can be used for both small-scale and large-scale construction projects. Its strength and durability make it suitable for various types of projects, regardless of their size. Additionally, steel formwork offers flexibility and can be easily customized to meet the specific requirements of different construction projects, making it a versatile choice for both small and large-scale construction.

- Q: How does steel formwork affect the quality of concrete?

- Steel formwork can have a significant impact on the quality of concrete in several ways. Firstly, steel formwork provides a rigid and stable structure that holds the concrete in place during the pouring and curing process. This ensures that the concrete maintains its desired shape and form, preventing any distortion or deformation. Secondly, steel formwork allows for precise and accurate construction of concrete structures. The smooth and even surface of steel formwork helps to create a uniform finish on the concrete, reducing the likelihood of surface imperfections such as air bubbles, honeycombing, or unevenness. This results in a higher quality and more aesthetically pleasing concrete finish. Furthermore, steel formwork offers better dimensional stability compared to other types of formwork materials. It is less susceptible to expansion or contraction due to temperature changes or moisture absorption, which can cause cracks or distortions in the concrete. This ensures that the structural integrity of the concrete remains intact, enhancing its overall quality and durability. Additionally, steel formwork provides excellent strength and load-bearing capacity. This allows for the construction of larger and more complex concrete structures with higher structural integrity. The sturdy nature of steel formwork ensures that the concrete can withstand heavy loads and external forces, reducing the risk of structural failures or collapses. Moreover, steel formwork is reusable, making it a cost-effective option in the long run. This not only contributes to sustainability but also ensures consistent quality in concrete construction. The ability to reuse steel formwork reduces the risk of formwork failure or deterioration that could affect the quality of subsequent concrete pours. In conclusion, steel formwork plays a crucial role in enhancing the quality of concrete. It provides stability, precision, dimensional stability, strength, and reusability, all of which contribute to the overall quality and durability of concrete structures.

- Q: What are the typical fire resistance ratings of steel formwork systems?

- Steel formwork systems can have varying fire resistance ratings due to factors like the type and thickness of the steel used, as well as the overall design and construction of the system. However, steel formwork systems are generally known for their high fire resistance properties. Steel, being a non-combustible material, does not contribute to the spread or intensity of fire. It has a high melting point and does not ignite or release flammable gases when exposed to fire. Consequently, steel formwork systems can withstand high temperatures and offer excellent fire resistance. Often, steel formwork systems are designed to meet or exceed specific fire resistance ratings set by building codes and regulations. These ratings are typically expressed in terms of time, such as 1 hour, 2 hours, or more, representing the duration for which the formwork system can maintain its structural integrity and protect against fire. To further enhance the fire resistance of steel formwork systems, additional measures like fire-resistant coatings or insulation materials can be incorporated. These measures provide an extra layer of protection, increasing the overall fire resistance of the formwork system. It's important to note that fire resistance ratings may also depend on other factors, such as the presence of fire-resistant materials in the surrounding structure and the implementation of overall fire safety measures in the building. Therefore, consulting with structural engineers, architects, and fire safety experts is crucial to determine the specific fire resistance requirements and ratings for steel formwork systems in a given construction project.

- Q: How does steel formwork accommodate for different concrete curing durations?

- Steel formwork can accommodate for different concrete curing durations by providing a sturdy and durable structure that can support the weight of the concrete during the curing process. The steel formwork is designed to be reusable, allowing for easy removal once the concrete has cured to the desired strength. This flexibility in formwork material enables construction projects to adapt to different curing durations without compromising the structural integrity of the concrete.

- Q: Can steel formwork be used for water storage tanks?

- Yes, steel formwork can be used for water storage tanks. Steel formwork is a popular choice for constructing water storage tanks due to its strength, durability, and ability to withstand the weight and pressure of the water. The steel formwork is designed to provide a rigid structure that can hold the concrete in place while it sets, ensuring a strong and watertight tank. Additionally, steel formwork can be easily assembled and disassembled, making it a practical option for constructing water storage tanks of various sizes and shapes. However, it is essential to ensure that the steel formwork is properly coated or treated to prevent corrosion from the water and other external elements.

- Q: Can steel formwork be customized for specific project requirements?

- Customization of steel formwork is possible to meet the specific requirements of a project. Steel, being highly versatile, can be shaped and molded easily to fit the unique needs of a project. This flexibility allows for the creation of different sizes, shapes, and designs to accommodate varying construction needs. On-site modification or adjustment of steel formwork is also achievable to align with the exact dimensions and specifications of a project. Furthermore, off-site pre-fabrication of steel formwork, tailored precisely to the project's requirements, is an option before transporting it to the construction site. By customizing steel formwork, it becomes suitable for a wide range of construction projects, including intricate structures, tall buildings, bridges, tunnels, and more.

- Q: How does steel formwork affect the overall labor requirements of a construction project?

- The overall labor requirements of a construction project can be greatly impacted by steel formwork in several ways. To start with, steel formwork is highly durable and robust, allowing it to be reused multiple times. This eliminates the need for labor-intensive tasks such as constantly building and taking down formwork, resulting in significant time and cost savings. In addition, steel formwork can be assembled and disassembled much faster than traditional timber formwork. This increased efficiency enables construction projects to progress at a quicker pace, reducing the overall duration of the project and minimizing labor needs. Furthermore, steel formwork provides greater dimensional accuracy and stability, leading to fewer adjustments and modifications during the construction process. This reduces the need for labor-intensive rework and ensures that the project stays on schedule. Moreover, steel formwork can be easily customized and fabricated to meet specific project requirements, allowing for faster and more precise construction. This eliminates the need for manual alterations and adjustments, saving both time and labor. Lastly, steel formwork creates a safer working environment for laborers. Its strong structure and ability to withstand heavy loads enhance worker safety, reducing the risk of accidents and injuries. This not only ensures the well-being of the workforce but also minimizes potential delays and labor requirements caused by injuries. In conclusion, steel formwork can significantly decrease the labor requirements of a construction project by streamlining the construction process, improving efficiency, increasing accuracy, and enhancing worker safety.

- Q: What are the common cost implications of using steel formwork in a construction project?

- The common cost implications of using steel formwork in a construction project include higher initial costs compared to other formwork materials, such as wood or plastic. However, steel formwork offers durability and can be reused multiple times, reducing the overall cost of formwork over the long term. Additionally, steel formwork provides better quality and accuracy in concrete finishing, saving costs on rework or repairs.

- Q: What are the different types of steel formwork corner solutions?

- There are several different types of steel formwork corner solutions available, including internal corners, external corners, and adjustable corners. Internal corners are used to create sharp angles within the formwork system, while external corners are used to form external edges and corners. Adjustable corners provide flexibility and can be adjusted to different angles as needed.

- Q: How does steel formwork contribute to the overall accuracy of concrete placement?

- There are several ways in which steel formwork contributes to the accuracy of concrete placement. Firstly, it provides a strong and stable structure, ensuring that the concrete is poured and cured in the desired shape and dimensions. The steel panels are designed to be resistant to deformation, reducing the risk of the formwork shifting or warping during pouring. Moreover, steel formwork allows for precise control over alignment and leveling. The panels can be easily adjusted and secured, ensuring that the concrete is poured at the intended level and alignment. This is particularly important for projects that require high accuracy, such as those with intricate architectural designs or precise measurements. Additionally, steel formwork offers the advantage of reusability. Unlike traditional wooden formwork, which can only be used a limited number of times, steel formwork can be used multiple times without compromising its structural integrity. This contributes to cost-effectiveness and consistent accuracy in concrete placement across various projects. Furthermore, the smooth surface of steel formwork helps achieve a high-quality finish on the concrete surface. The smooth panels minimize the risk of surface imperfections, ensuring a consistent texture and appearance. This is especially important for projects where the concrete will be exposed, such as architectural features or decorative elements. In conclusion, steel formwork is essential for maintaining accuracy in concrete placement. Its rigidity, adjustability, reusability, and smooth surface all contribute to achieving precise dimensions, alignment, and finish. This makes steel formwork a vital tool in construction projects that require high levels of accuracy and quality.

Send your message to us

Stair Tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords