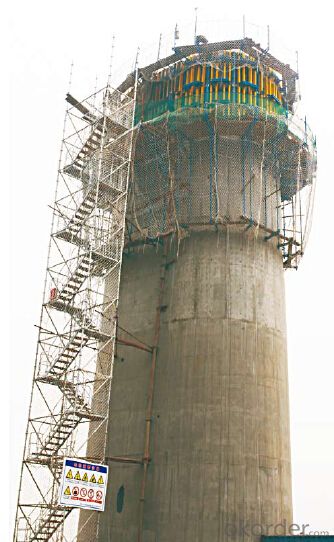

Stair-Tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: Can steel formwork be used in retail or commercial construction projects?

- Retail or commercial construction projects can benefit greatly from the use of steel formwork. This versatile and durable solution is ideal for creating concrete structures, offering numerous advantages. With its high reusability, excellent dimensional stability, and ability to handle high concrete pressures, steel formwork is a reliable choice. In these types of projects, steel formwork can be utilized for various applications including columns, walls, beams, slabs, and staircases. It provides a strong framework, ensuring accurate and smooth concrete placement, resulting in top-notch finishes. Moreover, steel formwork can be easily customized and adjusted to meet different project requirements, making it suitable for complex architectural designs. In addition to its flexibility, steel formwork also brings significant time and cost savings to construction projects. Its reusability minimizes the need for frequent formwork replacements, leading to reduced material and labor costs. The use of steel formwork further enhances construction efficiency by allowing for quick assembly, disassembly, and repositioning of formwork components. Overall, steel formwork is a dependable and efficient choice for retail or commercial construction projects, providing the necessary strength and flexibility for such applications.

- Q: What are the common quality control measures for steel formwork?

- Common quality control measures for steel formwork include: 1. Visual Inspection: This involves a thorough examination of the steel formwork to check for any visible defects or damage. Any signs of cracks, dents, or deformations should be identified and addressed. 2. Dimensional Accuracy: The dimensions of the steel formwork, such as the length, width, and height, should be measured and compared to the specified requirements. Any deviations from the required dimensions should be corrected. 3. Material Testing: Steel formwork should undergo material testing to ensure that it meets the required standards and specifications. This may involve testing the tensile strength, yield strength, hardness, and chemical composition of the steel. 4. Welding Inspection: If the steel formwork is welded, the quality of the welds should be inspected. This includes checking for proper penetration, fusion, and the absence of any defects like cracks or porosity. Non-destructive testing methods like ultrasonic or radiographic testing can be employed to ensure the integrity of the welds. 5. Surface Coating Inspection: The surface coating of the steel formwork, such as paint or galvanized coating, should be inspected for its thickness, adhesion, and uniformity. This ensures protection against corrosion and enhances the durability of the formwork. 6. Load Testing: Steel formwork should be subjected to load testing to evaluate its structural integrity and load-bearing capacity. This involves applying a known load to the formwork and monitoring its response to ensure it can safely support the required loads during construction. 7. Documentation and Record Keeping: Quality control measures should be documented and records should be maintained for future reference. This includes recording the inspection results, material test reports, and any corrective actions taken. These quality control measures help to ensure that steel formwork meets the required standards, specifications, and safety regulations, ultimately ensuring the structural integrity and performance of the formwork during construction.

- Q: Can steel formwork be used for commercial construction projects?

- Yes, steel formwork can be used for commercial construction projects. Steel formwork offers durability, strength, and the ability to withstand heavy loads, making it a suitable choice for large-scale construction projects such as commercial buildings. It provides a stable and reusable solution that allows for efficient and precise concrete placement, ensuring high-quality results.

- Q: How is steel formwork assembled and disassembled?

- Efficient construction processes are ensured by systematically and sequentially assembling and disassembling steel formwork. The foundation preparation marks the start of the assembly process, where the steel formwork components are arranged to match the desired shape and dimensions of the structure. To assemble the steel formwork, the first step involves connecting the vertical and horizontal components using various connecting devices like pins, bolts, or clips. These components, including panels, walers, and soldiers, are interlinked to create a rigid framework that offers the necessary support and shape for the concrete structure. Once the initial framework is assembled, the next step includes placing form ties or clamps that firmly secure the formwork panels in place. These ties or clamps are inserted through holes in the panels and tightly fastened on the opposite side to prevent any movement during the pouring and curing of the concrete. After the concrete has been poured and cured, the disassembly process begins. This process is carried out in reverse order, starting with removing the form ties or clamps. Once these are taken out, the formwork panels can be easily detached from the framework, allowing for the removal of the soldiers and walers. The disassembly of steel formwork also involves carefully dismantling the vertical and horizontal components, ensuring no damage is done to the framework or the panels. This is achieved by removing the connecting devices, such as pins, bolts, or clips, and systematically disassembling the various components. It is crucial to note that only experienced and trained professionals should handle the assembly and disassembly of steel formwork to guarantee safety and avoid any potential accidents or structural failures. Adhering to proper procedures and guidelines is essential for the successful completion of a construction project that utilizes steel formwork.

- Q: Can steel formwork be used for tall structures?

- Indeed, tall structures can be constructed using steel formwork. With its versatility and durability, steel formwork proves to be an excellent option for erecting towering buildings. Its notable advantages, including high strength, rigidity, and stability, make it the ideal choice for such structures. The ability of steel formwork to withstand the immense pressures exerted by fresh concrete ensures a smooth and uniform surface finish. Moreover, its reusability not only reduces construction costs but also minimizes the environmental impact. Furthermore, steel formwork allows for precise customization and effortless adaptation to various architectural designs and structural requirements. In conclusion, when it comes to constructing tall structures, steel formwork stands as a dependable and efficient solution.

- Q: What are the different types of steel formwork accessories available?

- There are several different types of steel formwork accessories available in the market. These accessories are designed to enhance the efficiency and effectiveness of steel formwork systems and make the construction process smoother. Some of the common types of steel formwork accessories include: 1. Formwork clamps: These clamps are used to secure the formwork panels together, ensuring stability and preventing any movement during the concrete pouring process. They come in various sizes and shapes to fit different formwork systems. 2. Formwork ties: These are used to hold the formwork panels together and provide additional support. Formwork ties are available in different lengths and materials to accommodate various formwork requirements. 3. Formwork connectors: These connectors are used to join the formwork panels at corners or intersections. They provide a strong and secure connection, ensuring proper alignment and stability of the formwork system. 4. Formwork wedges: These wedges are used to adjust the formwork panels and provide the desired level of inclination or angle. They are typically made of steel and can be easily inserted or removed to achieve the desired formwork configuration. 5. Formwork brackets: These brackets are used to support the formwork panels vertically or horizontally. They are adjustable and can be easily installed or removed to accommodate different formwork configurations. 6. Formwork spacers: These spacers are used to maintain a specific spacing between the formwork panels. They ensure consistent concrete thickness and prevent any bulging or deformation during the pouring process. 7. Formwork props: These props are used to support the formwork system and provide additional stability. They are adjustable in height and can be easily installed or removed as required. 8. Formwork anchors: These anchors are used to secure the formwork system to the ground or the existing structure. They provide stability and prevent any movement during the concrete pouring and curing process. Overall, these steel formwork accessories play a crucial role in ensuring the structural integrity and stability of the formwork system. They are designed to withstand high pressure and provide a reliable and efficient solution for construction projects.

- Q: How does steel formwork affect the overall labor productivity in construction?

- Steel formwork can have a significant impact on labor productivity in construction. Firstly, steel formwork is known for its durability and strength, which allows it to withstand the pressures and forces exerted during the concrete pouring process. This reduces the need for frequent repairs or replacements, minimizing downtime and increasing overall labor productivity. Additionally, steel formwork offers a high level of accuracy and precision in creating concrete structures. This results in better quality finishes and reduces the need for rework or corrections, saving time and effort for construction workers. The ability to achieve consistent dimensions and smooth surfaces with steel formwork also enhances the overall efficiency of the construction process. Furthermore, steel formwork is known for its ease of assembly and dismantling. The modular nature of steel formwork systems allows for quick and efficient setup, reducing the time spent on formwork erection. Similarly, the ease of dismantling enables faster turnaround times between construction phases, allowing workers to progress to the next task more swiftly. Moreover, steel formwork systems often incorporate features such as adjustable props, clamps, and connectors, making them highly adaptable to various construction requirements. This versatility enables workers to quickly adjust and modify the formwork to accommodate changes in design or construction plans, eliminating delays and improving labor productivity. Lastly, steel formwork can contribute to a safer working environment. The robustness and stability of steel formwork systems offer enhanced protection for construction workers, reducing the risk of accidents and injuries. By ensuring worker safety, steel formwork promotes a more efficient and productive construction process. In summary, steel formwork positively impacts labor productivity in construction by providing durability, accuracy, ease of assembly and dismantling, adaptability, and improved safety. These factors contribute to a more efficient construction process, reducing downtime, rework, and the overall time required for project completion.

- Q: Can steel formwork be used for both indoor and outdoor construction projects?

- Yes, steel formwork can be used for both indoor and outdoor construction projects. Steel is a highly durable and robust material that can withstand various weather conditions, making it suitable for outdoor projects. It provides excellent strength and stability, allowing it to support the weight of concrete and other construction materials. Additionally, steel formwork is reusable, which makes it a cost-effective choice for both indoor and outdoor projects. Its versatility and resilience make it a popular choice among construction professionals for various applications.

- Q: How does steel formwork affect the overall thermal insulation of a building?

- Steel formwork has minimal impact on the overall thermal insulation of a building. Since steel is a good conductor of heat, it does not provide sufficient insulation on its own. However, when combined with appropriate insulation materials, such as foam or mineral wool, steel formwork can contribute to a well-insulated building by providing structural support while the insulation material retains heat or cold temperatures.

- Q: Production of steel plate for bridge steel plate SPHC and Q235 which material is good? What is the difference?

- Represents the hot rolled steel plate (which corresponds to the cold rolled plate is SPCC)

Send your message to us

Stair-Tower for Formwork and Scaffolding System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords