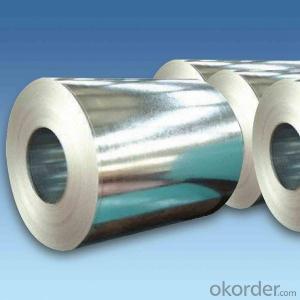

Stainless Steel Coils Cold Rolled NO.2B Finish Grade 304,304L,316,316L from China Suppilier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

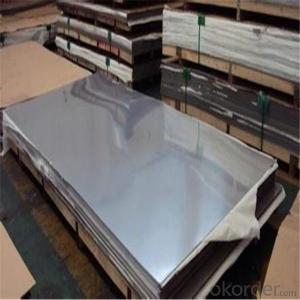

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

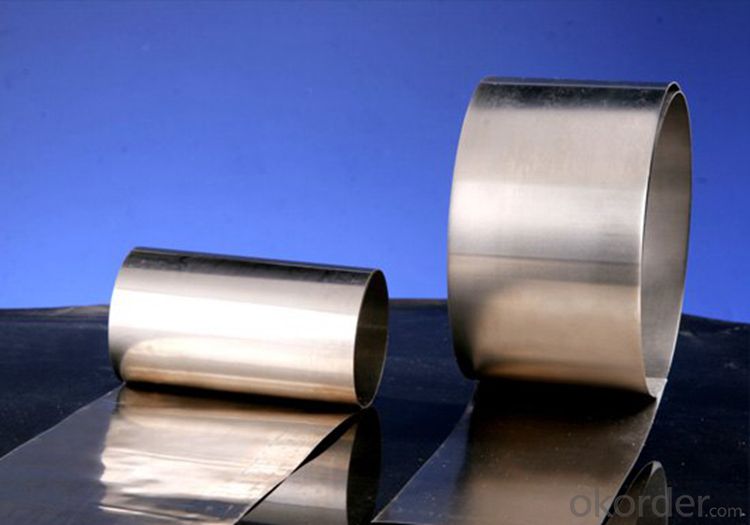

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for architectural railings?

- Yes, stainless steel sheets can be used for architectural railings. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it a popular choice for architectural applications such as railings. It offers strength and stability while also adding a sleek and modern look to any structure.

- Q: Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are generally resistant to abrasion. Stainless steel is known for its high strength and durability, making it less prone to scratches and wear compared to other materials. It has a smooth surface that can withstand friction and abrasion, making it suitable for various applications where resistance to scratches and wear is required. However, it is important to note that the level of resistance can vary depending on the specific grade and finish of stainless steel used.

- Q: What specifications do stainless steel plates have?

- General door with 304 doors or rust does not look good they will call you to change at a loss if you can go ah edge thickness wall door frame to plate factory they can count you can also tell them such as simple frame or Rome head of the door is generally

- Q: What are the fire resistance properties of stainless steel sheets?

- Stainless steel sheets have excellent fire resistance properties due to their high melting point and low thermal conductivity. They can withstand high temperatures without losing their structural integrity, making them suitable for use in fire-resistant applications.

- Q: What are the benefits of using brushed stainless steel sheets?

- There are several benefits of using brushed stainless steel sheets. Firstly, they have a visually appealing brushed finish that adds a modern and sophisticated touch to any space. Secondly, brushed stainless steel is highly durable and resistant to corrosion, making it suitable for various applications, including kitchen appliances, architectural elements, and automotive parts. Additionally, these sheets are easy to clean and maintain, as the brushed finish helps to hide fingerprints and smudges. Lastly, brushed stainless steel sheets are versatile and can be easily formed into different shapes, allowing for creative and customized designs.

- Q: Can stainless steel sheets be used for exterior cladding?

- Yes, stainless steel sheets can be used for exterior cladding. Stainless steel is highly resistant to corrosion, making it suitable for outdoor applications. It is durable, long-lasting, and provides an attractive aesthetic for building exteriors.

- Q: How do you form stainless steel sheets into different shapes?

- Stainless steel sheets can be formed into different shapes through various processes such as bending, rolling, and welding. The specific method used depends on the desired shape and the thickness of the stainless steel sheet. Bending is a common method used to form stainless steel sheets into shapes such as cylinders or boxes. This process involves clamping the sheet between a punch and a die and applying force to create the desired bend. The angle and radius of the bend can be controlled by adjusting the pressure and the distance between the punch and die. Rolling is another technique employed to form stainless steel sheets into curved or cylindrical shapes. This process involves passing the sheet through a set of rollers, which gradually bend the material into the desired shape. The diameter and curvature of the final shape can be adjusted by changing the spacing and alignment of the rollers. For more complex shapes, welding is often used in conjunction with bending or rolling. In this process, multiple stainless steel sheets are joined together using heat and pressure to create the desired form. This allows for the creation of intricate shapes, such as cones or irregular geometries. In addition to these methods, specialized equipment such as hydraulic presses or hydroforming can also be utilized to form stainless steel sheets into different shapes. These techniques involve applying high pressure or fluid pressure to the sheet, resulting in deformation and the desired shape. It is important to note that forming stainless steel sheets requires skilled operators and precise machinery to ensure accuracy and quality. Additionally, the properties of the stainless steel, such as its thickness and composition, can also influence the feasibility and success of the forming process.

- Q: Can stainless steel sheets be used for water filtration?

- Water filtration can indeed utilize stainless steel sheets. Stainless steel is renowned for its resistance to corrosion, durability, and ability to withstand high temperatures, making it an ideal material for water filtration purposes. Stainless steel sheets can be molded into various filter elements, including screens, mesh, or cartridges, which effectively eliminate impurities and contaminants from water. The small mesh size of stainless steel sheets allows for efficient filtration while maintaining a high flow rate. Moreover, stainless steel is non-reactive and does not release any harmful substances into the filtered water, ensuring its safety for consumption. In conclusion, stainless steel sheets are a dependable option for water filtration due to their exceptional mechanical properties and resistance to corrosion.

- Q: What does 8K stainless steel mean?

- 8K mirror surface definition: stainless steel surface after grinding and polishing, the surface is bright as a mirror, the photo reflects the person, commonly known as mirror 8K, it has corrosion resistance; and the mirror plate is the processing of follow-up color or etching board substrate. Mainly used in all kinds of decoration or metal optical products.

- Q: How do you remove water spots from stainless steel sheets?

- To remove water spots from stainless steel sheets, you can follow these simple steps: 1. Start by thoroughly cleaning the surface with a mild dish soap and warm water solution. This will remove any dirt or grime that may be contributing to the appearance of water spots. 2. Rinse the sheets with clean water and dry them completely using a soft cloth or towel. This step is important to prevent any new water spots from forming during the cleaning process. 3. Next, prepare a solution of equal parts white vinegar and water. Dip a clean cloth or sponge into the solution and wring out any excess liquid. 4. Gently rub the affected areas of the stainless steel sheets with the vinegar solution-soaked cloth or sponge. Be sure to follow the grain of the stainless steel to avoid scratching the surface. 5. After rubbing the water spots, rinse the sheets with clean water and dry them thoroughly once again with a soft cloth or towel. 6. If the water spots persist, you can try using a stainless steel cleaner or polish specifically designed for removing stains and water spots. Follow the instructions provided with the cleaner, and be sure to test it on a small, inconspicuous area first to ensure it does not damage the stainless steel. Remember to always use soft materials and gentle cleaning techniques when dealing with stainless steel to avoid scratching or damaging the surface.

Send your message to us

Stainless Steel Coils Cold Rolled NO.2B Finish Grade 304,304L,316,316L from China Suppilier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords