Cold Rolled Stainless Steel NO.2B Finish From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

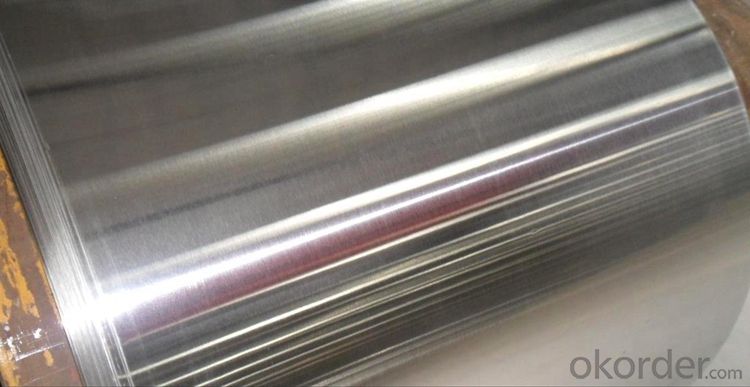

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be used for outdoor applications?

- Yes, stainless steel sheets can be used for outdoor applications. Stainless steel is highly resistant to corrosion, making it ideal for outdoor use where it will be exposed to moisture and other environmental factors. It is commonly used for outdoor structures, architectural elements, and equipment in industries such as construction, transportation, and marine.

- Q: How are stainless steel sheets installed?

- Different methods are used to install stainless steel sheets depending on the specific application and requirements. Here are several common installation methods for stainless steel sheets: 1. Adhesive: A popular and straightforward method involves using a specialized adhesive to bond the stainless steel sheet to the desired surface. The adhesive is applied to the back of the sheet, which is then firmly pressed onto the surface. This method is suitable for flat or slightly curved surfaces and results in a seamless and clean installation. 2. Mechanical fasteners: When additional strength and stability are necessary, stainless steel sheets can be installed using mechanical fasteners like screws, bolts, or rivets. These fasteners are drilled or screwed through the sheet and into the surface to secure it. This method is often used for installations that require resistance to external forces or for attaching stainless steel sheets to structural components. 3. Welding: In some cases, particularly for large or complex installations, welding may be employed to connect stainless steel sheets together or to other metal structures. Welding creates a strong and permanent bond between the sheets, ensuring a secure installation. However, this method requires skilled professionals and specialized equipment to ensure proper welding techniques and prevent damage to the stainless steel. 4. Magnetic attachment: Certain stainless steel sheets are designed with a magnetic backing, allowing them to be easily attached to magnetic surfaces. This method offers quick and convenient installation as the sheets can be easily repositioned or removed if necessary. However, it is important to ensure that the magnetic surface is clean and free from debris that could affect the adhesion. Before installing stainless steel sheets, it is crucial to thoroughly clean the surface and remove any dirt, dust, or grease. This preparation will help ensure a secure and long-lasting installation. Additionally, following the manufacturer's instructions and guidelines specific to the stainless steel sheet being installed is essential for achieving the best results.

- Q: What are the different types of stainless steel sheet finishes for decorative purposes?

- There are several types of stainless steel sheet finishes commonly used for decorative purposes, including brushed, mirror, embossed, and patterned finishes.

- Q: Can stainless steel sheets be used for insulation?

- No, stainless steel sheets cannot be used for insulation. Stainless steel is a good conductor of heat and electricity, so it would not provide adequate insulation.

- Q: What are the different surface patterns available for stainless steel sheets?

- Stainless steel sheets offer a variety of surface patterns that each have their own unique appeal and practical benefits. One popular choice is the brushed finish, achieved by using a fine abrasive material to brush the surface of the sheet. This creates an elegant pattern of parallel lines and gives the sheet a sophisticated appearance. Moreover, the brushed finish helps to conceal scratches and fingerprints, making it a practical option for applications where appearance matters. Another commonly used surface pattern is the mirror finish, attained by polishing the sheet to create a highly reflective and glossy surface. This finish is often preferred in architectural and decorative settings where a sleek and luxurious look is desired. Additionally, the mirror finish is easy to clean and maintain. Embossed or textured patterns are also available for stainless steel sheets. These patterns are created by stamping or rolling the sheet with a specific design, resulting in raised or recessed areas on the surface. This not only adds visual interest but also enhances grip and slip resistance, making it suitable for flooring or industrial equipment. Furthermore, there are perforated stainless steel sheets with small holes or slots in a specific pattern. These sheets are commonly used in architecture for decorative screens or facades, as well as for filtration or ventilation purposes. The perforations can be customized in various shapes and sizes to meet specific requirements. In conclusion, the choice of surface pattern for stainless steel sheets depends on the desired appearance, functionality, and application. Whether it's the sleek brushed or mirror finish, the textured embossed patterns, or the versatile perforated sheets, there is a wide range of options available to suit different needs.

- Q: Do stainless steel sheets require any special handling or storage?

- Yes, stainless steel sheets do require some special handling and storage to maintain their quality and prevent damage. Here are a few key points to consider: 1. Handling: When handling stainless steel sheets, it is important to wear gloves to avoid leaving fingerprints and oils on the surface, which can lead to corrosion. Additionally, sharp tools should be avoided while handling to prevent scratching the surface. 2. Cleaning: Prior to storage, stainless steel sheets should be thoroughly cleaned to remove any dirt, debris, or moisture. This helps to prevent the formation of rust or corrosion during storage. Mild soap or a specialized stainless steel cleaner can be used for cleaning. 3. Storage: Stainless steel sheets should be stored in a clean, dry, and well-ventilated area. They should be kept away from direct sunlight, extreme temperatures, and moisture, as these factors can lead to corrosion. Ideally, they should be stored in a covered area or wrapped in protective materials like plastic or cloth to prevent scratches and damage. 4. Separation: It is important to separate different sheets to avoid contact and potential scratching or damage. This can be achieved by using dividers or interleaf papers between the sheets. 5. Handling equipment: When moving or transporting stainless steel sheets, it is recommended to use appropriate handling equipment like forklifts or cranes. This ensures safe and secure movement without causing any dents or scratches. By following these handling and storage guidelines, stainless steel sheets can be effectively protected and maintained in optimal condition for their intended use.

- Q: Can stainless steel sheets be used for exterior cladding?

- Indeed, exterior cladding can utilize stainless steel sheets. The robustness and resistance to corrosion of stainless steel make it appropriate for various purposes, including cladding. Stainless steel sheets present exceptional endurance against weathering, UV rays, and extreme temperatures, rendering them perfect for external usage. They can endure severe environmental conditions, such as heavy rain, snow, and strong winds, without deteriorating or losing their aesthetic charm. Moreover, stainless steel sheets are available in an extensive array of finishes, allowing for customization and design adaptability. Whether for residential, commercial, or industrial edifices, stainless steel cladding offers a durable and visually pleasing solution.

- Q: Can stainless steel sheets be used for elevator cladding?

- Yes, stainless steel sheets can be used for elevator cladding. Stainless steel is a popular material choice for elevator cladding due to its durability, resistance to corrosion, and aesthetic appeal. It provides a sleek and modern look to elevators, making it a preferred option for many architects and designers. Stainless steel sheets are available in various finishes, such as brushed, mirrored, or patterned, allowing for customization and flexibility in design. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for high-traffic areas like elevators. Overall, stainless steel sheets offer a durable and visually appealing solution for elevator cladding.

- Q: How do stainless steel sheets compare to other types of metal sheets?

- Stainless steel sheets possess numerous advantages that distinguish them from alternative metal sheets. Firstly, stainless steel exhibits a high level of resistance to corrosion, rendering it an optimal selection for applications where durability and longevity are of utmost importance. Unlike other metals, stainless steel does not readily rust or stain, thereby guaranteeing the preservation of its appearance and functionality even in challenging environments. Secondly, stainless steel sheets are renowned for their strength and robustness. They possess a significant tensile strength, enabling them to endure heavy loads without undergoing bending or warping. This attribute renders stainless steel sheets suitable for a wide array of applications, including the construction, automotive, and manufacturing industries. Another notable advantage of stainless steel sheets lies in their hygienic properties. Stainless steel is non-porous and non-absorbent, facilitating easy cleaning and maintenance. Additionally, it exhibits resistance to bacterial growth, making it a favored choice for medical equipment, food processing facilities, and kitchen appliances. Furthermore, stainless steel sheets offer exceptional heat resistance. They can withstand high temperatures without compromising their structural integrity or developing any deformities, making them suitable for applications involving extreme heat or thermal cycling. Lastly, stainless steel sheets are available in a variety of finishes and textures, granting versatility in terms of design options. Whether one prefers a polished, brushed, or matte finish, stainless steel allows for customization to fulfill any aesthetic requirement. In conclusion, stainless steel sheets surpass other types of metal sheets due to their exceptional resistance to corrosion, strength, hygienic properties, heat resistance, and aesthetic versatility. These qualities establish stainless steel sheets as the preferred choice for numerous industries, ensuring durability, reliability, and longevity across various applications.

- Q: What is the fire resistance rating of stainless steel sheets?

- The fire resistance rating of stainless steel sheets varies depending on their thickness and grade, but generally, stainless steel exhibits good fire resistance properties due to its high melting point and low thermal conductivity.

Send your message to us

Cold Rolled Stainless Steel NO.2B Finish From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords