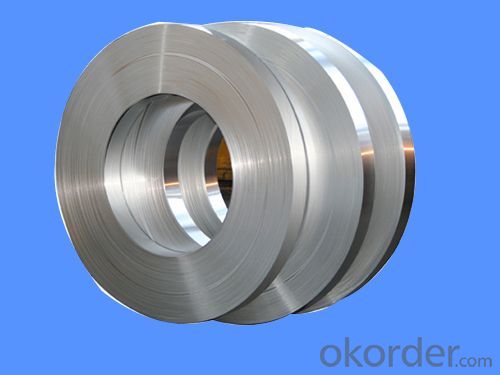

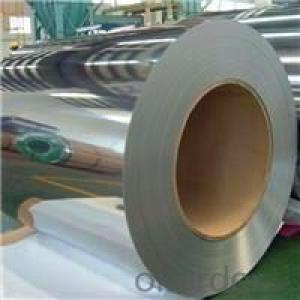

High Quality 201 Coil Stainless Steel Plate/Sheet in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of goods:Stainless steel plate/Stainless steel coil

Place of Origin:China(Mainland)

Brand Name:TISCO,POSCO,LISCO,BAOSTEEL,JISCO,YONGJIN METAL,EASTERN SPECIAL STEEL,FAR EAST NEW MATERIALect

Model Number:

201/202/301/302/303/303CU/304/304L/304F/304H/304J1/310/310S/314/314L/316/316L/321 //420/430/ 316/316L/316TI

Minimum Order Quantity:20 ton

Packaging Details:Standard export packing or According to customer's requirement

Delivery Time:Within 7-15 Days After Order Confirmed

Payment Terms:T/T, L/C, D/P

Price terms:FOB, CFR, CIF, EXW

Supply Ability:1000 tons per month

Applications:

applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Used for equipments in chemical, coal and the petrochemical industry that request to high corrosion resistance-outdoor machine, architectural materiel, heat-resistant assembly and assemblies that hart to heat treatment. Stainless steel plate also can be made according to the customer's requirements.

Detailed Product Description

Product Name: | Stainless Steel Plates | Thickness: | According to customer's requirement |

Standard: | ASTM, AISI, JIS, EN, DIN, GB | Technology: | Hot Rolled |

Width: | 1000mm,1250mm,1500mm,1800mm,2000mm | Surface: | No.1,2B,No.4,Polishing 8K, Wire Drawing |

- Q: Can stainless steel strips be used in the semiconductor industry?

- Yes, stainless steel strips can be used in the semiconductor industry. Stainless steel is known for its excellent corrosion resistance, high strength, and durability, making it a suitable material for various applications in the semiconductor industry. Stainless steel strips are often used in the fabrication of semiconductor equipment, such as chambers, wafer carriers, and process tools, where they can withstand harsh environments and high temperatures. Additionally, stainless steel strips can be precision-engineered to meet specific requirements, ensuring dimensional accuracy and reliability in semiconductor manufacturing processes.

- Q: Are stainless steel strips suitable for HVAC systems?

- Indeed, HVAC systems find stainless steel strips to be a fitting choice. Stainless steel, known for its resistance to corrosion, can endure the harsh conditions and elevated temperatures typically encountered in HVAC systems. Its durability and longevity, coupled with its exceptional heat transfer properties, make it an ideal material. Given its strength, corrosion resistance, and capacity to uphold cleanliness and hygiene, stainless steel strips are frequently utilized in fabricating HVAC system components such as ductwork and heat exchangers. Moreover, the ease of cleaning and maintenance associated with stainless steel strips contributes to their widespread use in HVAC applications.

- Q: How are stainless steel strips used in construction?

- Stainless steel strips are commonly used in construction for various purposes such as framing, structural support, and finishing touches. They are often utilized as reinforcement in concrete structures, providing additional strength and durability. Stainless steel strips are also employed in the fabrication of building components like beams, columns, and lintels due to their resistance to corrosion and high strength-to-weight ratio. Additionally, these strips are utilized for cladding and decorative purposes, adding a sleek and modern aesthetic to architectural designs.

- Q: What are the different types of corrosion that can affect stainless steel strips?

- Stainless steel strips can be affected by various types of corrosion. Let's explore these different types: 1. General corrosion: The surface of the stainless steel strip undergoes a uniform attack, resulting in a widespread loss of material. This happens when the protective oxide layer on the stainless steel gets damaged or compromised, usually due to exposure to aggressive chemicals or high temperatures. 2. Pitting corrosion: Localized corrosion occurs, creating small pits or holes on the surface of the stainless steel strip. This happens when specific aggressive chemicals or environments penetrate the protective oxide layer, causing localized breakdown and corrosion. 3. Crevice corrosion: Corrosion takes place in narrow gaps or crevices on the stainless steel strip, such as those between overlapping materials or under gaskets. These crevices provide an environment where aggressive chemicals can accumulate, leading to localized corrosion. 4. Stress corrosion cracking (SCC): This type of corrosion occurs under tensile stress while being exposed to a corrosive environment. It can cause the stainless steel strip to fail suddenly, even at stress levels lower than its yield strength. SCC is often associated with exposure to certain chemicals or environments, such as chlorides or sulfides. 5. Intergranular corrosion: Grain boundaries of the stainless steel strip are affected, resulting in localized corrosion along these boundaries. This occurs when the stainless steel is exposed to certain conditions, such as high temperatures or welding, which can cause sensitization and subsequent corrosion along the grain boundaries. 6. Galvanic corrosion: When stainless steel comes into electrical contact with a different metal in the presence of an electrolyte like water or saltwater, galvanic corrosion occurs. The electrical potential difference between the two metals leads to accelerated corrosion of the less noble metal (in this case, stainless steel). To ensure the longevity and performance of stainless steel strips, it is crucial to consider these various types of corrosion when selecting the appropriate stainless steel grade and implementing proper corrosion prevention measures.

- Q: Can stainless steel strips be used in electronics applications?

- Indeed, electronics applications can make use of stainless steel strips. Stainless steel is renowned for its impressive corrosion resistance, remarkable strength, and exceptional durability, rendering it apt for a multitude of electronic components and applications. It finds frequent application in the production of connectors, terminals, springs, battery contacts, and shielding, among other uses. Stainless steel strips offer electrical conductivity, thermal stability, and resistance to both vibration and mechanical stress, hence ensuring their reliability in electronic devices. Furthermore, the non-magnetic nature of stainless steel can prove advantageous in specific scenarios where minimizing magnetic interference is required.

- Q: How do you clean and maintain stainless steel strips?

- To clean and maintain stainless steel strips, start by wiping them with a soft cloth or sponge soaked in warm soapy water. Rinse them thoroughly and dry them with a clean towel to prevent water spots. For tougher stains or fingerprints, use a stainless steel cleaner or a mixture of vinegar and water. Avoid using abrasive cleaners or scrubbing pads as they can scratch the surface. Regularly wiping the strips with a microfiber cloth will help maintain their shine and prevent buildup of dirt or grease.

- Q: Can stainless steel strips be used for solar water heaters?

- Yes, stainless steel strips can be used for solar water heaters. Stainless steel is a durable and corrosion-resistant material that can withstand the harsh conditions of solar water heating systems. It is commonly used for the construction of the collector panels, heat exchangers, and pipes in solar water heaters.

- Q: What are the common uses of stainless steel strips in the textile industry?

- Stainless steel strips are commonly used in the textile industry for various purposes such as fabric reinforcement, belt fastening, and tensioning systems. They provide strength and durability to fabrics, ensuring they can withstand the rigors of textile production processes. Additionally, stainless steel strips are also used in textile machinery, including looms and knitting machines, to facilitate smooth and efficient operations.

- Q: Are stainless steel strips suitable for architectural signage?

- Yes, stainless steel strips are suitable for architectural signage. Stainless steel is a popular choice for architectural applications due to its durability, aesthetic appeal, and resistance to corrosion. It is a versatile material that can be easily formed into different shapes and sizes, making it suitable for creating various types of signage, including letters, logos, and plaques. Stainless steel strips offer a sleek and modern look that can complement any architectural design. They can be finished in different ways, such as brushed, polished, or etched, to achieve the desired visual effect. The material also provides excellent weather resistance, making it suitable for both indoor and outdoor signage. In addition to its aesthetic qualities, stainless steel is a highly durable material that can withstand harsh environmental conditions. It is resistant to corrosion, rust, and fading, ensuring that the signage remains visually appealing and readable for a long time. This makes stainless steel strips a reliable choice for architectural signage, especially in high-traffic areas or locations exposed to extreme weather conditions. Furthermore, stainless steel is a low maintenance material, requiring minimal upkeep to keep it in top condition. It is easy to clean and maintain, making it a cost-effective choice in the long run. Overall, stainless steel strips are a suitable option for architectural signage due to their durability, aesthetic appeal, resistance to corrosion, and low maintenance requirements. Whether for commercial buildings, residential complexes, or public spaces, stainless steel signage can add a touch of sophistication and professionalism to any architectural project.

- Q: What is the fatigue strength of stainless steel strips?

- The fatigue strength of stainless steel strips can vary depending on various factors such as the specific grade of stainless steel, the surface condition, and the manufacturing process. However, in general, stainless steel is known for its high fatigue strength compared to other materials. Stainless steel strips are commonly used in applications where they are subject to cyclic loading or repetitive stress, such as in the automotive, aerospace, and construction industries. The fatigue strength refers to the maximum stress level that a material can withstand for a specific number of cycles without failure. The fatigue strength of stainless steel strips is typically evaluated through fatigue testing, where a strip specimen is subjected to repeated loading and unloading cycles until failure occurs. The results are then used to determine the endurance limit or fatigue limit of the material, which represents the stress level below which the material can withstand an infinite number of cycles without failure. Depending on the grade of stainless steel, the fatigue strength can range from 150 to 500 megapascals (MPa). However, it is important to note that the fatigue strength can be influenced by various factors including the surface finish, presence of any defects or notches, temperature, and environmental conditions. In conclusion, stainless steel strips generally have high fatigue strength compared to other materials. The specific fatigue strength can vary depending on the grade of stainless steel and other factors, and it is typically determined through fatigue testing.

Send your message to us

High Quality 201 Coil Stainless Steel Plate/Sheet in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords