Stainless steel plate/sheet 304/304L,201,202,310S,316L,316Ti,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

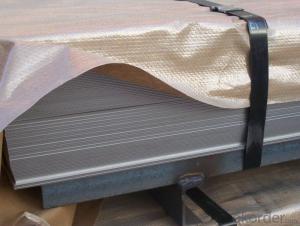

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: What are the different types of stainless steel sheets?

- There are several different types of stainless steel sheets available, each with its own unique properties and uses. Some of the most common types include: 1. Austenitic stainless steel sheets: This is the most widely used type of stainless steel, known for its excellent corrosion resistance and high ductility. It is non-magnetic and can be easily formed, making it suitable for various applications such as kitchen equipment, architectural structures, and automotive components. 2. Ferritic stainless steel sheets: This type of stainless steel has a lower chromium content compared to austenitic stainless steel. It possesses good corrosion resistance in certain environments and is often used in applications that require high temperature resistance, such as industrial ovens and exhaust systems. 3. Martensitic stainless steel sheets: Martensitic stainless steel is known for its high strength and hardness. It is magnetic and offers good corrosion resistance, making it suitable for applications that require both strength and corrosion resistance, such as knives, turbine blades, and valve parts. 4. Duplex stainless steel sheets: This type of stainless steel combines the properties of both austenitic and ferritic stainless steels. It has excellent corrosion resistance, high strength, and good weldability. Duplex stainless steel is commonly used in industries such as chemical processing, oil and gas, and marine environments. 5. Precipitation-hardening stainless steel sheets: This type of stainless steel is heat treatable, offering high strength and excellent corrosion resistance. It is commonly used in applications that require high strength-to-weight ratio, such as aerospace components, springs, and shafts. These are just a few examples of the different types of stainless steel sheets available. The choice of which type to use depends on the specific requirements of the application, including factors such as corrosion resistance, strength, formability, and cost.

- Q: Can stainless steel sheets be used for elevator panels?

- Indeed, elevator panels can make use of stainless steel sheets. Stainless steel, being highly durable, strong, and visually appealing, is a favored material for elevator panels. Its resistance to corrosion, damage, and wear makes it ideal for high-traffic regions such as elevators. Furthermore, stainless steel panels are effortless to clean and maintain, which is crucial for preserving a pristine and polished appearance within elevators. Moreover, stainless steel can be easily tailored and manufactured to suit precise elevator dimensions and design necessities. All in all, stainless steel sheets represent a dependable and adaptable choice for elevator panels.

- Q: Can stainless steel sheets be used for fire-rated applications?

- Yes, stainless steel sheets can be used for fire-rated applications. Stainless steel is known for its high melting point and excellent heat resistance properties. It retains its strength and integrity even at high temperatures, making it a suitable material for fire-rated applications. Stainless steel sheets are often used in fire-rated doors, walls, and ceilings, providing a durable and reliable barrier against fire. Additionally, stainless steel's corrosion resistance properties make it a long-lasting option, ensuring its effectiveness in fire-rated applications over time.

- Q: How do I calculate the strength of stainless steel sheets?

- To calculate the strength of stainless steel sheets, you need to consider several factors such as the material's tensile strength, yield strength, and elongation. Tensile strength refers to the maximum amount of stress a material can withstand before breaking. It is usually measured in pounds per square inch (psi) or megapascals (MPa). To determine the tensile strength of stainless steel sheets, you can refer to the material's specification sheet provided by the manufacturer or consult engineering handbooks. Yield strength, on the other hand, represents the stress at which a material begins to deform permanently. It is an important parameter to consider when designing structures or selecting materials. The yield strength of stainless steel sheets can also be found in the material's specification sheet or engineering references. Elongation, commonly expressed as a percentage, indicates the extent to which a material can stretch or deform before breaking. Higher elongation values suggest greater ductility. The elongation of stainless steel sheets can be determined through tensile testing or obtained from material specifications. These three parameters - tensile strength, yield strength, and elongation - provide insight into the overall strength and performance of stainless steel sheets. It is essential to consider these factors when evaluating the suitability of stainless steel sheets for specific applications or designing structures that require a particular strength level.

- Q: Are stainless steel sheets resistant to stress corrosion cracking?

- Yes, stainless steel sheets are generally resistant to stress corrosion cracking due to their high levels of chromium and nickel, which create a protective oxide layer on the surface. This layer prevents the initiation and propagation of corrosion cracks under tensile stress.

- Q: Can stainless steel sheets be used for desalination plants?

- Yes, stainless steel sheets can be used for desalination plants. Stainless steel is highly resistant to corrosion, which makes it an ideal material for desalination plants where saltwater is being processed. The durability and longevity of stainless steel sheets also make them suitable for withstanding the harsh conditions and high pressures involved in the desalination process.

- Q: Can stainless steel sheets be used for chemical storage tanks?

- Yes, stainless steel sheets can be used for chemical storage tanks. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for storing chemicals, including acids, alkalis, and other corrosive substances. The high strength and durability of stainless steel ensure that the tanks can withstand the pressure and weight of the stored chemicals. Additionally, stainless steel is non-reactive, meaning it does not react with most chemicals, ensuring the purity and integrity of the stored substances. Stainless steel's smooth surface also makes it easy to clean and maintain, reducing the risk of contamination. Overall, stainless steel sheets are a reliable and suitable choice for chemical storage tanks.

- Q: How do you polish stainless steel sheets?

- To polish stainless steel sheets, you can follow a few simple steps. First, ensure that the surface is clean and free from any dirt or debris. You can use a mild detergent or stainless steel cleaner to remove any stains or marks. Next, use a soft cloth or sponge to apply a stainless steel polish or a combination of vinegar and olive oil. Apply the polish in the direction of the grain, which is usually a linear pattern on the surface of stainless steel. Once the polish is applied, use another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to shine and appear polished. If necessary, repeat the process in areas that require additional polishing, and ensure that all excess polish is wiped away to avoid streaks or residue. It is important to note that different stainless steel finishes may require specific polishing techniques or products. Always refer to the manufacturer's instructions or guidelines for best results.

- Q: How do I prevent finger marks on stainless steel sheets?

- To prevent finger marks on stainless steel sheets, you can try a few simple steps. Firstly, make sure to clean the sheets regularly using a mild detergent or stainless steel cleaner to remove any existing fingerprints. Next, consider applying a protective coating or film specifically designed for stainless steel surfaces, which can provide a barrier against smudges and fingerprints. Additionally, try to handle the sheets with clean and dry hands to minimize the transfer of oils and dirt. Finally, consider using microfiber or lint-free cloths for cleaning instead of rough materials that can leave scratches or streaks.

- Q: What drill can drill stainless steel?

- Cobalt bit, hard alloy drill bit, can drill stainless steel.

Send your message to us

Stainless steel plate/sheet 304/304L,201,202,310S,316L,316Ti,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords