Stainless steel plate/sheet 304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

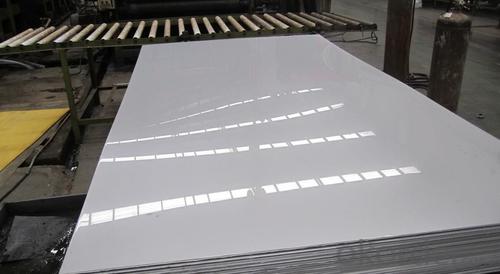

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: Are stainless steel sheets available in different finishes?

- Yes, stainless steel sheets are available in different finishes.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Yes, stainless steel sheets can be customized in terms of size and shape. Stainless steel is a highly versatile material that can be easily manipulated and transformed to meet specific requirements. Whether it is a large sheet or a small one, stainless steel can be cut, shaped, and resized to fit the desired dimensions. This customization process can be achieved through various techniques such as cutting, bending, welding, and forming. Additionally, stainless steel sheets can also be perforated or embossed to add further customization and enhance their aesthetic appeal. Overall, stainless steel sheets offer great flexibility in terms of size and shape customization, making them suitable for a wide range of applications in industries such as construction, automotive, aerospace, and more.

- Q: How do you remove water stains from stainless steel sheets?

- To remove water stains from stainless steel sheets, you can try using vinegar or lemon juice. Apply either of these ingredients onto the stained area, let it sit for a few minutes, and then gently rub the stain with a soft cloth or sponge. Rinse the area with water and dry it thoroughly. If the stain persists, you can also consider using a stainless steel cleaner specifically designed for removing water stains.

- Q: What does stainless steel plate mean?

- The stainless steel plate is divided into two kinds of hot-rolled and cold-rolled parts according to the method of manufacture, including the thickness of 0.02-4 mm thin cold plate and 4.5-50 mm medium plate. According to the structural characteristics of steel, they can be divided into 5 types: austenite type, austenite ferrite type, ferrite type, martensite type and precipitation hardening type. Can withstand oxalic acid, sulfuric acid iron sulfate, nitrate, nitrate acid and hydrofluoric acid, sulfuric acid copper sulfate, phosphoric acid, formic acid and acetic acid and various acid corrosion, widely used in chemical, food, medicine, papermaking, petroleum, atomic energy industry, as well as construction, kitchen utensils, cutlery, household appliances, vehicles of all kinds of parts. In order to ensure the mechanical properties of various kinds of stainless steel sheet, such as yield strength, tensile strength, elongation and hardness, the steel plate must be annealed, treated by solution, aging treatment before delivery.

- Q: What are the benefits of using diamond plate stainless steel sheets in industrial flooring?

- Using diamond plate stainless steel sheets in industrial flooring offers numerous advantages. Firstly, their exceptional durability and strength make them highly resistant to wear and tear. The diamond pattern on the surface enhances their structural integrity, making them particularly suitable for protecting against damage caused by heavy machinery, equipment, and foot traffic. The stainless steel construction also ensures that the sheets are resistant to corrosion, extending their lifespan and reducing maintenance costs. Secondly, diamond plate stainless steel sheets provide superior slip resistance. The raised diamond pattern on the surface increases traction, making it safer and easier for workers to move around the industrial floor. This is especially important in environments where spills, oils, or other liquids are present, as it helps prevent slip and fall accidents and injuries. Additionally, these sheets are hygienic and easy to clean. The smooth surface and corrosion-resistant properties of stainless steel prevent dirt, grime, and bacteria buildup. This is crucial in industries such as food processing, pharmaceuticals, or healthcare, where maintaining a clean and sanitary environment is of utmost importance. Furthermore, diamond plate stainless steel sheets enhance the overall appearance of the industrial space. The diamond pattern adds a modern and industrial touch, creating a professional and visually appealing environment. Lastly, these sheets are versatile and can be easily customized to meet various industrial flooring requirements. They are available in different sizes, thicknesses, and grades, allowing for flexibility in design and installation. This adaptability makes them suitable for a wide range of applications, including factory floors, warehouses, garages, and outdoor areas. In conclusion, diamond plate stainless steel sheets offer durability, slip resistance, hygiene, aesthetic appeal, and versatility when used in industrial flooring. These advantages make them an excellent choice for ensuring a safe, long-lasting, and visually appealing flooring solution in industrial settings.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- A variety of stainless steel sheet embossing patterns are available, offering different visual and tactile effects. Some of the most commonly used patterns are: 1. Diamond: This pattern consists of evenly spaced diamond-shaped indentations across the sheet's surface, creating an appealing textured appearance. 2. Linen: Resembling the texture of linen fabric, this pattern features parallel lines running in one direction and intersecting perpendicular lines, adding a subtle and sophisticated look to stainless steel sheets. 3. Stucco: The stucco pattern creates a raised, pebble-like texture on the sheet's surface, commonly used in architectural applications to enhance visual interest and provide a tactile feel. 4. Leather: This pattern imitates the texture of leather, with irregular lines and indentations, giving stainless steel sheets a unique and luxurious appearance. 5. Hammered: The hammered pattern showcases irregular indentations resembling hammer marks, contributing to a rustic and handcrafted look on stainless steel sheets. 6. Checkerboard: This pattern forms a grid of squares, with alternating squares raised or recessed, resulting in a classic and geometric design on stainless steel sheets. 7. Wave: The wave pattern showcases curved lines resembling ocean waves, adding a dynamic and flowing look to stainless steel sheets. These examples represent only a fraction of the available stainless steel sheet embossing patterns. Each pattern can be customized in terms of size, depth, and spacing to meet specific design preferences and application requirements.

- Q: Are stainless steel sheets suitable for food preparation surfaces?

- Yes, stainless steel sheets are highly suitable for food preparation surfaces. Stainless steel is non-porous, hygienic, and resistant to corrosion, making it a preferred material for food preparation. It is also easy to clean and does not react with acidic or alkaline foods, ensuring that it maintains the quality and taste of the prepared food.

- Q: How do you determine the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can be determined using various methods such as the Rockwell hardness test, Brinell hardness test, or Vickers hardness test. These tests involve applying a specific amount of force or pressure to the surface of the steel sheet and measuring the depth of indentation created. The hardness value obtained from these tests indicates the resistance of the stainless steel sheet to deformation or scratching, thus providing a measure of its hardness.

- Q: What are the costs of stainless steel sheets compared to other materials?

- The costs of stainless steel sheets can vary depending on several factors such as the grade, thickness, size, and finish of the sheets. Generally, stainless steel sheets tend to be more expensive than other materials like aluminum or mild steel. This is primarily due to the higher production costs and the unique properties of stainless steel. Stainless steel is known for its corrosion resistance, durability, and aesthetic appeal, which makes it a popular choice in various industries such as construction, automotive, and manufacturing. However, these desirable qualities come at a higher price point. Compared to aluminum sheets, stainless steel sheets are typically more expensive. Aluminum is a lightweight material with good corrosion resistance, but it is not as strong or durable as stainless steel. Therefore, stainless steel is often preferred in applications where strength and longevity are crucial. When compared to mild steel, stainless steel sheets are also more costly. Mild steel is a commonly used material due to its affordability, but it lacks the corrosion resistance and aesthetic appeal of stainless steel. Stainless steel is often chosen over mild steel in applications where exposure to moisture, chemicals, or harsh environments is a concern. It is important to consider the specific requirements of the project when evaluating the costs of stainless steel sheets compared to other materials. While stainless steel may have a higher upfront cost, its long-term benefits, such as reduced maintenance and replacement costs, can often outweigh the initial investment. Additionally, the unique properties of stainless steel may make it the only viable choice for certain applications, further justifying its higher cost.

- Q: What is the machinability of stainless steel sheets?

- The machinability of stainless steel sheets can vary depending on the grade of stainless steel and its specific composition. Generally, stainless steel is known to have lower machinability compared to other types of metals such as carbon steel or aluminum. This is mainly due to its higher strength, hardness, and work-hardening characteristics. Stainless steel has a tendency to work-harden during machining, leading to increased cutting forces and tool wear. It also has a lower thermal conductivity, which can result in higher temperatures during machining operations, further contributing to tool wear. Additionally, stainless steel has a unique chip formation behavior, often resulting in stringy and difficult-to-break chips. However, advancements in cutting tool technology and machining techniques have made it possible to improve the machinability of stainless steel. For instance, using appropriate cutting tool geometries, coatings, and coolant/lubricant can help reduce cutting forces, minimize tool wear, and improve chip control. It is important to note that different grades of stainless steel can exhibit varying machinability. Austenitic stainless steels, such as 304 and 316, are generally more difficult to machine compared to ferritic or martensitic stainless steels. This is due to their higher nickel and chromium content, which contribute to their superior corrosion resistance but also make them harder to machine. Overall, while stainless steel sheets may present some challenges in machining, with the right tools, techniques, and experience, it is possible to achieve satisfactory machinability and produce high-quality components from stainless steel sheets.

Send your message to us

Stainless steel plate/sheet 304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords