Stainless steel plate/sheet 304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

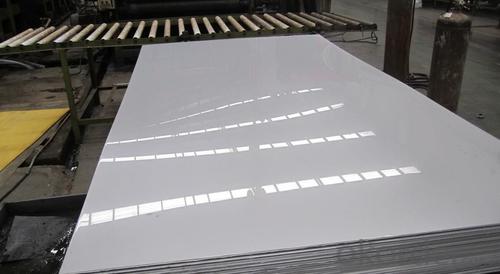

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

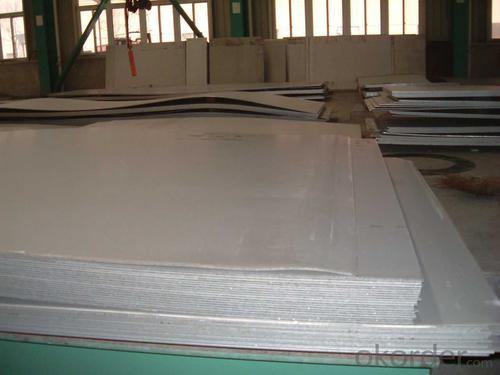

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: What are the different thickness tolerances for stainless steel sheets?

- There are various thickness tolerances for stainless steel sheets depending on the specific grade and industry standards. Generally, the thickness tolerances for stainless steel sheets can range from ±0.0015 inches to ±0.030 inches, with tighter tolerances being more common for precision applications.

- Q: Are stainless steel sheets suitable for food processing?

- Indeed, stainless steel sheets prove to be an excellent choice for food processing purposes. The food and beverage industry extensively utilizes stainless steel owing to its exceptional properties and hygienic characteristics. Notably, it does not react with food, is highly resistant to corrosion, and does not introduce any taste or smell to the processed food. Moreover, stainless steel is effortless to clean and upkeep, rendering it an optimal selection for food processing machinery, worktops, and various other surfaces. Additionally, it withstands elevated temperatures and effectively resists bacterial proliferation, thereby establishing itself as a reliable and secure material for food processing activities.

- Q: Can stainless steel sheets be embossed or textured?

- Yes, stainless steel sheets can be embossed or textured. This process involves imparting a pattern or design onto the surface of the stainless steel sheet through the use of specialized machinery and techniques. Embossing creates a raised pattern, while texturing creates a textured or brushed finish on the surface of the stainless steel sheet. These techniques can be used to add aesthetic appeal to stainless steel sheets, making them suitable for various applications such as architectural, decorative, or industrial purposes. Additionally, embossed or textured stainless steel sheets can also provide functional benefits such as improved grip or reduced glare.

- Q: Are stainless steel sheets resistant to corrosion?

- Yes, stainless steel sheets are generally highly resistant to corrosion due to the presence of chromium in their composition, which forms a protective oxide layer on the surface. This oxide layer acts as a barrier, preventing the metal from being exposed to corrosive elements and ensuring its durability in various environments.

- Q: Are stainless steel sheets suitable for storage cabinets?

- Yes, stainless steel sheets are suitable for storage cabinets. They are strong, durable, and resistant to corrosion, making them ideal for long-term storage. Additionally, stainless steel has a sleek and modern appearance, making it a popular choice for both residential and commercial storage cabinets.

- Q: Are stainless steel sheets suitable for water tanks?

- Stainless steel sheets are indeed a great option for water tanks. Their resistance to corrosion makes them perfect for water storage. They won't react with the water or introduce any harmful substances into it. Additionally, stainless steel tanks are durable, require little maintenance, and have a long lifespan. They can handle high temperatures and extreme weather conditions without compromising their structural integrity. Moreover, stainless steel is non-porous, preventing the growth of bacteria and algae. These outstanding characteristics make stainless steel sheets a superb choice for water tanks in different settings, such as residential, commercial, and industrial environments.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness of stainless steel sheets varies depending on the specific type and grade of stainless steel. Typically, stainless steel sheets are available in thicknesses ranging from 0.4mm to 6.0mm. Thinner sheets are commonly utilized for flexible and lightweight applications, whereas thicker sheets are typically employed for structural purposes requiring increased strength and durability. It is worth mentioning that customized thicknesses can be manufactured to meet specific project requirements.

- Q: Can stainless steel sheets be used for kitchen appliances?

- Yes, stainless steel sheets can be used for kitchen appliances. Stainless steel is a popular material choice for kitchen appliances due to its durability, resistance to corrosion, and easy maintenance. It is commonly used for making ovens, refrigerators, dishwashers, and other kitchen appliances. Stainless steel sheets are versatile and can be easily formed into various shapes and sizes to fit different appliance designs. Additionally, stainless steel has a sleek and modern appearance, making it a preferred choice for many homeowners and chefs.

- Q: What are the different types of perforations available for stainless steel sheets?

- There are several different types of perforations available for stainless steel sheets, each serving a specific purpose and offering unique characteristics. Here are some of the most common types: 1. Round Perforations: These are the most basic and widely used type of perforations. They consist of evenly spaced round holes punched through the stainless steel sheet. Round perforations offer good airflow and visibility while providing adequate strength and durability. 2. Square Perforations: Similar to round perforations, square perforations feature evenly spaced square holes instead of round ones. Square perforations are often preferred when a more geometric and modern aesthetic is desired, as they can create a visually appealing pattern. 3. Slotted Perforations: Slotted perforations are characterized by elongated, rectangular holes that are punched through the stainless steel sheet. This type of perforation allows for better drainage and airflow, making it suitable for applications such as grilles, screens, and filters. 4. Hexagonal Perforations: Hexagonal perforations feature hexagon-shaped holes that are punched through the stainless steel sheet. This type of perforation offers an interesting visual pattern and can provide better strength and rigidity compared to round or square perforations. 5. Decorative Perforations: These perforations are specifically designed to enhance the aesthetic appeal of stainless steel sheets. They can come in various shapes, sizes, and patterns, including floral, geometric, or custom designs. Decorative perforations are often used in architectural applications, interior design, and decorative panels. 6. Micro Perforations: Micro perforations are extremely small holes that are closely spaced in the stainless steel sheet. They are commonly used in applications where a high level of precision and fine filtering is required, such as speaker grilles, ventilation systems, or sieves. It's important to note that the availability of specific perforation types may vary depending on the supplier or manufacturer. Additionally, some suppliers may offer custom perforation options to meet unique requirements or design preferences.

- Q: How do you prevent crevice corrosion on stainless steel sheets?

- To minimize the occurrence of crevice corrosion on stainless steel sheets, there are several steps that can be taken: 1. Maintaining cleanliness and performing regular maintenance: It is crucial to keep the stainless steel sheets clean and free from any contaminants. Regular cleaning using mild detergent and water, followed by thorough rinsing and drying, helps eliminate potential corrosive agents. 2. Avoiding the accumulation of debris or moisture: Ensuring that there are no crevices or gaps where debris or moisture can accumulate is essential. Regular inspection and maintenance can help identify and rectify any such areas. Additionally, maintaining effective drainage systems and preventing water pooling can help prevent moisture accumulation, which contributes to crevice corrosion. 3. Applying protective coatings: The application of protective coatings on the stainless steel sheets provides an additional barrier against crevice corrosion. Various types of coatings, such as paints, epoxy coatings, or specialized corrosion-resistant coatings designed for stainless steel, are available. 4. Using suitable gaskets and sealants: When fastening or joining stainless steel sheets, it is important to utilize compatible gaskets and sealants. These components should be corrosion-resistant and act as barriers against moisture and contaminants. Silicone-based sealants or gaskets made from PTFE (polytetrafluoroethylene) are commonly employed for this purpose. 5. Preventing galvanic corrosion: Galvanic corrosion can arise when dissimilar metals come into contact with each other in the presence of an electrolyte, leading to corrosion of the less noble metal. To prevent this, it is crucial to avoid using dissimilar metals in close proximity to stainless steel sheets. When necessary, insulating materials or coatings can be used to separate them. 6. Conducting regular inspections and maintenance: Regularly inspecting the stainless steel sheets for any indications of corrosion and promptly addressing them is crucial in preventing crevice corrosion. This includes checking for signs of pitting, discoloration, or degradation of the protective coatings. Any identified issues should be promptly resolved to prevent further corrosion. By adhering to these preventive measures, crevice corrosion on stainless steel sheets can be effectively minimized, thus ensuring their longevity and preserving their aesthetic appeal.

Send your message to us

Stainless steel plate/sheet 304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords