Grade 201 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade 201 Stainless Steel Round Bar in stock

Descriptio of Grade 201 Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade 201 Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

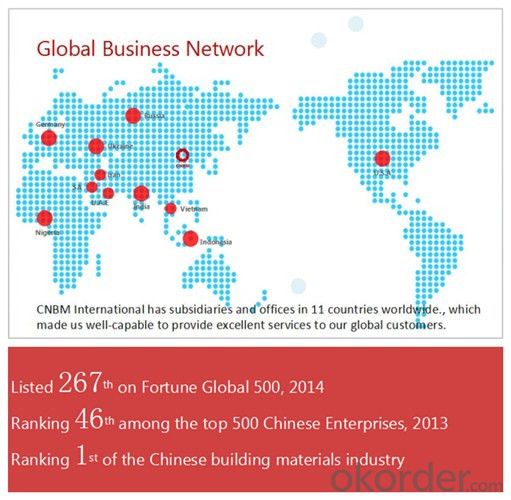

Company Information of Grade 201 Steel Round Bar in Stock

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade 201Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What is the role of special steel in the defense industry?

- Special steel plays a critical role in the defense industry due to its unique properties and capabilities. One of the primary functions of special steel in defense is to provide strength and durability to various components and structures of military equipment, such as tanks, armored vehicles, naval vessels, and aircraft. These steels are designed to withstand extreme conditions, including high impact and ballistic resistance, making them essential for ensuring the safety and protection of military personnel. Another significant role of special steel in the defense industry is its contribution to the production of cutting-edge weaponry. Special steel alloys are used to manufacture firearms, missiles, and artillery systems, providing the necessary strength, hardness, and corrosion resistance required for such applications. These steels allow for the precise manufacturing of complex weapon systems, ultimately enhancing their performance, accuracy, and reliability. Moreover, special steel also plays a vital role in the defense industry by enabling the development of advanced communication and electronics technologies. Steel alloys with specific magnetic properties are utilized in the production of radar systems, satellite components, and other electronic devices critical for military surveillance, intelligence, and communication purposes. These steels enable the efficient transmission and reception of signals, enhancing the overall capabilities of defense systems. In summary, special steel is indispensable in the defense industry due to its strength, durability, and unique properties. It provides the necessary foundation for the construction of military equipment, enhances the performance of weapons, and enables the development of advanced communication and electronics technologies. By utilizing special steel, the defense industry can ensure the safety, effectiveness, and technological superiority of military operations.

- Q: What are the different heat treatment processes used for special steel?

- There are several heat treatment processes commonly used for special steel, including annealing, normalizing, quenching, tempering, and case hardening. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which helps to improve its ductility and relieve internal stresses. Normalizing is similar to annealing but involves air cooling the steel after heating, resulting in a more uniform grain structure. Quenching is a process where the steel is rapidly cooled in a liquid medium, such as water or oil, to achieve high hardness and strength. Tempering follows quenching and involves reheating the steel to a lower temperature, reducing its hardness and increasing toughness. Case hardening is a surface hardening process where the steel is heated in the presence of a carbon-rich material, creating a hardened outer layer while maintaining a softer core. These heat treatment processes are used to enhance the mechanical properties and performance of special steel for various applications.

- Q: How does special steel contribute to the renewable energy aftermarket industry?

- Enhancing the efficiency, durability, and cost-effectiveness of renewable energy systems, special steel plays a critical role in the aftermarket industry. Wind turbine components are one of the primary beneficiaries of special steel in this industry. To withstand harsh environmental conditions and generate electricity efficiently, wind turbines require materials that are both high-strength and corrosion-resistant. Special steel alloys, such as high-strength low-alloy (HSLA) steel and stainless steel, offer exceptional mechanical properties, fatigue resistance, and corrosion resistance, making them an ideal choice for critical wind turbine components like rotor blades, tower structures, and more. By incorporating special steel into wind turbine manufacturing, the aftermarket industry can enjoy several advantages. Turbine lifespan is extended, maintenance costs are reduced, and energy output is improved. The strength and durability of special steel also allow for the construction of taller and larger wind turbine towers, enabling the installation of turbines in areas with lower wind speeds. This expansion of suitable locations maximizes the potential for energy production, making wind energy a more viable and widespread renewable energy source. Additionally, special steel contributes to the aftermarket industry through its application in solar power systems. Solar panels require sturdy mounting structures to handle the weight of the panels, withstand wind and snow loads, and ensure optimal sun exposure. Special steel, with its high strength-to-weight ratio and corrosion resistance, is commonly used in these mounting structures, providing long-lasting and reliable support for solar panels. Moreover, special steel finds applications in other renewable energy systems such as hydroelectric power plants and geothermal systems. These industries benefit from the corrosion resistance and ability to withstand extreme temperatures offered by special steel, ensuring the longevity and efficiency of the equipment. Overall, special steel plays a significant role in driving the growth and adoption of renewable energy sources worldwide. By enabling the production of reliable, durable, and efficient renewable energy systems, special steel contributes to the success of the aftermarket industry. Whether in wind turbines, solar panels, or other renewable energy technologies, special steel enhances performance and longevity, ultimately advancing the use of renewable energy sources on a global scale.

- Q: What are the factors affecting the cost of special steel?

- The cost of special steel can be influenced by various factors. The price of raw materials is one of the primary factors. Special steel often requires specific alloys or additives, which can be expensive to obtain. Any fluctuations in the prices of these raw materials can directly affect the final product's cost. Another factor is the complexity of the manufacturing process. Advanced techniques and machinery are often used to produce special steel, and acquiring and maintaining them can be costly. The more intricate and specialized the manufacturing process, the higher the steel's cost. The demand and supply dynamics also play a role in determining the cost of special steel. If there is high demand but limited supply, the price is likely to go up. Conversely, if there is low demand and excessive supply, the price may decrease. Moreover, the level of customization required for the special steel can impact its cost. If a customer needs specific dimensions, tolerances, or surface finishes, additional processing steps may be necessary, leading to higher costs. Furthermore, transportation and logistics costs can affect the overall cost of special steel. If the steel needs to be transported over long distances or requires specialized handling, these additional expenses can accumulate. Lastly, market conditions and economic factors can influence the cost of special steel. Inflation, currency exchange rates, and overall economic stability can all have an impact on the pricing of special steel. In conclusion, the cost of special steel is determined by a combination of factors, including raw material costs, manufacturing complexity, demand and supply dynamics, customization requirements, transportation and logistics costs, and market conditions.

- Q: What are the different heat treatment furnaces used for special steel?

- Different heat treatment furnaces used for special steel include annealing furnaces, tempering furnaces, hardening furnaces, and quenching furnaces.

- Q: How is maraging steel used in the production of aerospace components?

- Maraging steel is commonly used in the production of aerospace components due to its desirable properties such as high strength, toughness, and resistance to corrosion. It is used to manufacture various parts including landing gears, rocket motor casings, and turbine discs. Its unique combination of strength and ductility allows for the production of lightweight and durable components, ultimately enhancing the overall performance and safety of aerospace systems.

- Q: How does special steel contribute to the oil and gas equipment industry?

- Special steel plays a crucial role in the oil and gas equipment industry as it offers exceptional strength, corrosion resistance, and durability. It is used in the manufacturing of various critical components such as pipes, valves, fittings, and offshore platforms. Special steel's high heat resistance and ability to withstand extreme pressure and harsh environments make it an ideal choice for oil and gas equipment, ensuring reliability and safety in operations.

- Q: How does special steel contribute to reducing product downtime due to repairs?

- Special steel contributes to reducing product downtime due to repairs by providing enhanced durability and resistance to wear and tear. Its unique composition and properties enable it to withstand harsh conditions, such as high temperatures, corrosion, and mechanical stress. This reduces the frequency of repairs and maintenance required for products, resulting in less downtime. Additionally, special steel's high strength and toughness allow for the design of more reliable components, ensuring longer operational life and minimizing the need for frequent repairs.

- Q: What are the cost considerations when using special steel?

- The cost considerations when using special steel include the price of the raw materials, as special steel typically contains alloying elements that can be expensive. Additionally, the manufacturing process for special steel may require specialized equipment and techniques, which can increase production costs. Furthermore, special steel may have specific requirements for heat treatment or machining, which can add to the overall cost. However, the use of special steel can offer benefits such as improved strength, corrosion resistance, or heat resistance, which can justify the higher costs in certain applications.

- Q: What are the different applications of stainless special steel?

- Stainless special steel, which is also known as stainless steel, is a highly versatile material that is used in various industries because of its unique properties. Some examples of the different ways in which stainless special steel is utilized include: 1. Construction: Stainless steel is widely employed in the construction industry due to its exceptional durability and resistance to corrosion. It is used in structural components, bridges, building facades, and roofing materials. 2. Automotive industry: The automotive sector extensively utilizes stainless steel because of its strength, ability to withstand high temperatures, and durability. It can be found in exhaust systems, mufflers, catalytic converters, fuel tanks, and various other components. 3. Medical equipment: Stainless steel is the preferred material in the medical field because of its high resistance to corrosion and biocompatibility. It is used in the production of surgical instruments, implants, orthopedic devices, and medical equipment. 4. Food processing industry: Stainless steel is widely employed in the food industry because of its hygienic properties. It is used in the manufacturing of food processing equipment, storage tanks, food preparation surfaces, and utensils. 5. Aerospace industry: Stainless steel is utilized in the aerospace industry for its strength, ability to withstand high temperatures, and resistance to corrosion. It is used in the production of aircraft parts, engine components, and structural elements. 6. Chemical industry: Stainless steel is highly resistant to corrosion from various chemicals, making it suitable for applications in the chemical industry. It is used in the manufacturing of tanks, pipes, valves, and other equipment that come into contact with corrosive substances. 7. Energy sector: Stainless steel is used in the energy industry for various purposes. It is employed in the construction of power plants, oil and gas refineries, pipelines, and renewable energy systems such as wind turbines and solar panels. 8. Marine industry: Stainless steel is extensively used in marine environments because of its excellent resistance to corrosion. It is used in the production of boat fittings, propellers, underwater structures, and offshore platforms. 9. Household appliances: Stainless steel is commonly used in household appliances because of its attractive appearance, durability, and resistance to stains and scratches. It can be found in kitchen appliances such as refrigerators, ovens, dishwashers, and washing machines. 10. Art and design: Stainless steel is increasingly being employed in art installations, sculptures, and architectural designs because of its aesthetic appeal, versatility, and ability to withstand outdoor conditions. In conclusion, stainless special steel is utilized in a wide range of industries due to its durability, resistance to corrosion, strength, ability to withstand high temperatures, and aesthetic appeal. It plays a crucial role in construction, automotive, medical, food processing, aerospace, chemical, energy, marine, household appliances, and artistic fields.

Send your message to us

Grade 201 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords