Stainless Steel Plate 430 with Standard Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

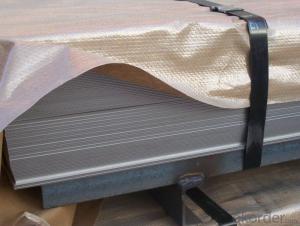

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the different types of stainless steel sheet surface treatments available?

- There are several different types of stainless steel sheet surface treatments available, each offering unique benefits and appearances. Some of the most common surface treatments include: 1. No.1 Finish: This is a hot-rolled, annealed, and pickled surface finish that is commonly used for industrial applications. It has a rough texture with visible grain lines. 2. No.2B Finish: Also known as a bright, cold-rolled finish, it is obtained by annealing and pickling. It provides a smooth and reflective surface with a moderate level of gloss. 3. No.3 Finish: This is a finely polished surface obtained by using gradually finer abrasive materials. It has a semi-reflective appearance and is often used for decorative applications. 4. No.4 Finish: Similar to No.3 finish, but with a higher level of polish. It has a satin-like appearance and is commonly used in architectural and kitchen equipment applications. 5. BA (Bright Annealed) Finish: This is a mirror-like, highly reflective finish achieved by annealing the stainless steel sheet in a controlled atmosphere. It is commonly used for decorative purposes and in the production of household appliances. 6. Embossed Finish: This treatment involves stamping the stainless steel sheet with a pattern to create a textured surface. It is often used for decorative purposes or to provide grip on surfaces. 7. Colored Finish: Stainless steel sheets can also be treated with different colored coatings, such as gold, black, or bronze. These finishes are achieved through processes like PVD (Physical Vapor Deposition) or electroplating. Each surface treatment offers its own advantages and is suitable for specific applications. It is important to consider factors such as durability, corrosion resistance, aesthetic appeal, and intended use when selecting the appropriate surface treatment for a stainless steel sheet.

- Q: What's the difference between 304 stainless steel and 301 stainless steel?

- 301, compared with 304 steel material, C content is much, Cr and Ni content is little, cold processing tensile strength and hardness increased, without magnetism, but after cold processing has magnetism

- Q: What are the color options for stainless steel sheets?

- Stainless steel sheets are typically available in a range of color choices, contingent upon the particular finish employed on the surface. The prevalent color selections for stainless steel sheets encompass silver, representing the inherent hue of stainless steel, in addition to black, gold, bronze, and copper. These hues are attained through techniques like powder coating, PVD coating, or chemical treatments, which establish a thin coating on the sheet's surface. The assortment of color choices grants enhanced design flexibility and the ability to select hues that harmonize with diverse aesthetics and applications.

- Q: What type of welding rod is used for 304 stainless steel plate welding?

- A102 is Cr19Ni10 stainless steel electrode titanium calcium type coating, corrosion resistance of the deposited metal has good mechanical properties and resistance to intergranular, has excellent welding performance and anti porosity property, anti cracking, red medicine Pinai. A107 is a Cr19Ni10 stainless steel electrode with alkaline coating. The deposited metal has good mechanical properties and intergranular corrosion resistance. Therefore, they are aimed at 304 development of welding electrodes.

- Q: Can stainless steel sheets be recycled after use?

- Yes, stainless steel sheets can be recycled after use. Stainless steel is a highly recyclable material, and its properties make it ideal for recycling. The recycling process for stainless steel involves melting down the sheets to extract the raw materials, which can then be used to produce new stainless steel products. Recycling stainless steel not only helps conserve natural resources but also reduces energy consumption and greenhouse gas emissions associated with the production of new stainless steel. Therefore, it is highly recommended to recycle stainless steel sheets to promote sustainability and circular economy practices.

- Q: Can stainless steel sheets be used for medical implants or devices?

- Yes, stainless steel sheets can be used for medical implants or devices. Stainless steel is a common material used for medical implants and devices due to its excellent corrosion resistance, strength, and biocompatibility. It is often used for applications such as orthopedic implants (like hip replacements and bone plates), surgical instruments, dental implants, and cardiovascular devices. Stainless steel sheets can be precisely fabricated into the desired shape and size for various medical applications, ensuring durability and long-term functionality. Additionally, stainless steel can be easily sterilized, making it suitable for use in medical environments.

- Q: Are stainless steel sheets resistant to high temperatures?

- Stainless steel sheets are generally resistant to high temperatures, thanks to their excellent heat resistance properties. They are suitable for a wide range of applications that require withstanding high temperatures. This is due to the composition of stainless steel, which includes chromium, nickel, and other alloying elements. These elements create a protective oxide layer on the surface of the steel, acting as a barrier against oxidation and preventing corrosion or weakening at elevated temperatures. The structural integrity of stainless steel sheets remains intact even at temperatures up to approximately 1500°F (815°C). However, it is important to note that the temperature resistance may vary depending on the specific grade and thickness of the stainless steel sheet. To ensure accurate information for high-temperature applications, it is advisable to consult the manufacturer's specifications or seek professional advice.

- Q: Can stainless steel sheets be used for elevator shafts?

- Yes, stainless steel sheets can be used for elevator shafts. Stainless steel is a durable and corrosion-resistant material that is commonly used in construction for its strength and aesthetic appeal. Elevator shafts require materials that can withstand constant use and exposure to various elements, making stainless steel an ideal choice.

- Q: What glue does the board and the stainless steel stick to?

- Application of epoxy resin adhesive is widely used in bonding of various metals and alloys, ceramics, glass, wood, cardboard, plastic, concrete, stone, bamboo and other non-metal materials, or bonding of metal and non-metallic materials. For untreated polyethylene, polypropylene, PTFE, polystyrene, PVC and other plastic without adhesion, for rubber, leather, fabric and other soft material adhesive ability is also poor.

- Q: What is the stainless steel grid board? What areas of stainless steel mesh panels are used in?

- Stainless steel grid plate, also called stainless steel steel grid plate, the two are the same product, just name different

Send your message to us

Stainless Steel Plate 430 with Standard Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords