Stainless steel sheet standard Size #4 Polish Treatments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

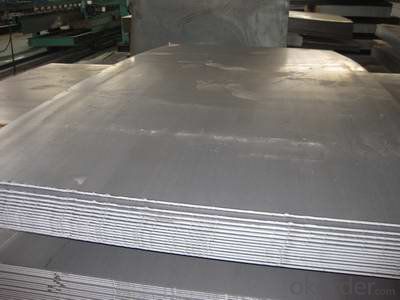

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

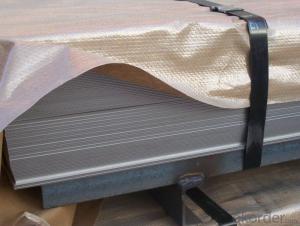

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

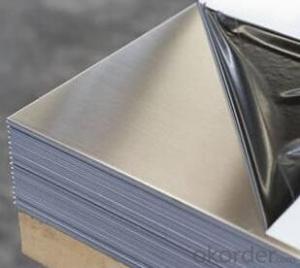

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for architectural applications?

- Yes, stainless steel sheets are highly suitable for architectural applications. They possess a sleek and modern appearance, excellent corrosion resistance, durability, and can withstand various environmental conditions. Additionally, stainless steel sheets offer versatility in terms of design possibilities and can be easily fabricated and installed, making them a popular choice in architectural projects.

- Q: Can stainless steel sheets be recycled?

- Yes, stainless steel sheets can be recycled. Stainless steel is a highly recyclable material, and its recycling rate is one of the highest among all materials. When stainless steel sheets reach the end of their useful life, they can be collected and sent to a recycling facility. The recycling process involves melting down the stainless steel sheets and reforming them into new products, without losing their properties or quality. This makes stainless steel a sustainable and environmentally friendly material choice. Recycling stainless steel also helps to conserve natural resources, reduce energy consumption, and minimize waste.

- Q: Can stainless steel sheets be used as a backsplash in kitchens?

- Yes, stainless steel sheets can be used as a backsplash in kitchens. They are a popular choice due to their durability, heat resistance, and easy maintenance. Stainless steel backsplashes can add a sleek and modern look to the kitchen while also providing a hygienic and easy-to-clean surface.

- Q: Are stainless steel sheets resistant to corrosion?

- Yes, stainless steel sheets are generally highly resistant to corrosion due to the presence of chromium in their composition, which forms a protective oxide layer on the surface. This oxide layer acts as a barrier, preventing the metal from being exposed to corrosive elements and ensuring its durability in various environments.

- Q: What are the different types of stainless steel sheet finishes for pharmaceutical applications?

- Some of the different types of stainless steel sheet finishes for pharmaceutical applications include 2B finish, 2D finish, BA finish, and mirror finish.

- Q: Are stainless steel sheets good for pressure vessels?

- Yes, stainless steel sheets are commonly used for pressure vessels and are considered to be a good choice. Stainless steel offers excellent resistance to corrosion, high strength, and good mechanical properties, making it suitable for applications that require withstanding high pressures. Additionally, stainless steel has good heat resistance, which is important in pressure vessels where high temperatures may be encountered. It is also worth noting that stainless steel can be easily formed and welded, allowing for the fabrication of complex shapes and designs required for pressure vessel construction. Overall, stainless steel sheets are a preferred material for pressure vessels due to their durability, reliability, and ability to meet the demanding requirements of such applications.

- Q: Can stainless steel sheets be used for stairs and railings?

- Stairs and railings can indeed utilize stainless steel sheets. This remarkably resilient and adaptable material frequently finds its place in architectural and interior design endeavors. With its corrosion resistance, stainless steel proves suitable for outdoor settings and environments with elevated humidity or chemical exposure. The malleability of stainless steel sheets allows for their fabrication into diverse forms and dimensions, rendering them perfect for crafting stairs and railings with an elegant and contemporary appearance. Furthermore, stainless steel boasts effortless cleanliness and maintenance, thus making it a pragmatic selection for high-traffic areas or public spaces.

- Q: Can stainless steel sheets be used for cryogenic storage containers?

- Yes, stainless steel sheets can be used for cryogenic storage containers. Stainless steel has excellent low-temperature properties, including high strength, corrosion resistance, and good thermal conductivity, making it suitable for storing materials at extremely low temperatures in cryogenic applications.

- Q: What factors affect the cost of stainless steel sheets?

- There are several factors that can affect the cost of stainless steel sheets. These include the type and grade of stainless steel, the thickness and size of the sheets, the quantity being purchased, market demand and availability, production and labor costs, and any additional processing or finishing requirements.

- Q: Are stainless steel sheets suitable for medical applications?

- Stainless steel sheets are appropriate for medical purposes, indeed. The medical sector widely opts for stainless steel because of its remarkable ability to resist corrosion, its durability, and its ease of sterilization. Medical equipment, surgical instruments, implants, and even architectural applications in healthcare facilities commonly employ stainless steel. Due to its resistance to stains, bacterial growth, and contamination, stainless steel is considered a hygienic and safe material for medical usage. Moreover, its strength and minimal maintenance needs render it suitable for prolonged use in challenging medical environments. All in all, stainless steel sheets satisfy the strict requirements of medical applications and are a dependable choice for healthcare professionals.

Send your message to us

Stainless steel sheet standard Size #4 Polish Treatments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords