Stainless Steel Hot Rolled Sheet And Slab And Plates Stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled Stainless steel sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

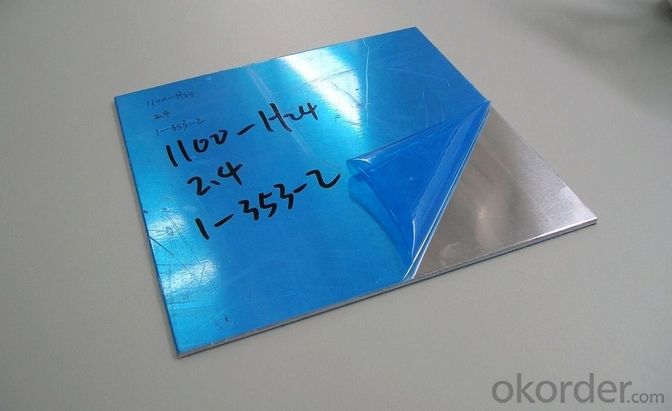

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: What is the minimum order quantity for stainless steel sheets?

- The minimum order quantity for stainless steel sheets can vary depending on the supplier and the specific type and size of the sheets. It is recommended to contact the supplier directly to inquire about their minimum order quantity.

- Q: Can stainless steel sheets be used for automotive applications?

- Certainly, automotive applications can make use of stainless steel sheets. Renowned for its versatility and durability, stainless steel proves to be an exceptional material that exhibits remarkable resistance against corrosion, heat, and impact. These exceptional qualities render it highly suitable for automotive applications wherein durability and resistance against harsh environments are crucial aspects. Stainless steel sheets find utility across various domains of the automotive industry, encompassing body panels, exhaust systems, fuel tanks, and even interior components. Moreover, stainless steel can be effortlessly shaped, welded, and manipulated to meet precise design prerequisites, thus solidifying its status as a favored option within the automotive industry.

- Q: Can stainless steel sheets be used for outdoor applications?

- Yes, stainless steel sheets can be used for outdoor applications. Stainless steel is highly resistant to corrosion, making it an ideal material for outdoor use. It can withstand exposure to moisture, saltwater, and extreme weather conditions without rusting or deteriorating. Stainless steel sheets are commonly used in outdoor structures such as fences, handrails, roofs, and cladding. They are also used in outdoor appliances, equipment, and decorative elements. Additionally, stainless steel sheets can be painted or coated to further enhance their resistance to outdoor elements and to match the desired aesthetic. Overall, stainless steel sheets are a durable and reliable choice for outdoor applications.

- Q: How do you clean and maintain stainless steel sheets?

- To clean and maintain stainless steel sheets, you'll need a few basic supplies: a microfiber cloth or soft sponge, mild dish soap or stainless steel cleaner, warm water, and a towel for drying. Start by rinsing the stainless steel sheet with warm water to remove any loose dirt or grime. Then, apply a small amount of mild dish soap onto the microfiber cloth or sponge and gently scrub the surface of the stainless steel sheet. Avoid using abrasive materials or harsh chemicals as they can scratch or damage the stainless steel. After cleaning, rinse the sheet thoroughly with warm water to remove any soap residue. To prevent water spots, wipe the surface dry with a clean towel. Make sure to always dry the stainless steel sheet after cleaning to prevent water spots or streaks. If there are stubborn stains or fingerprints that won't come off with soap and water, you can use a stainless steel cleaner specifically designed for this purpose. Follow the instructions on the cleaner and use a soft cloth to apply it to the sheet. Wipe in the direction of the grain to avoid scratching the surface. Rinse thoroughly and dry as mentioned earlier. To maintain the shine and luster of stainless steel sheets, it's important to avoid using abrasive cleaners, scouring pads, or steel wool, as they can damage the surface. Also, be careful not to use cleaners containing bleach or chlorine as they can cause discoloration. Regularly cleaning the stainless steel sheets is essential to prevent buildup of dirt, grease, or other contaminants that can lead to corrosion. A weekly cleaning routine should suffice for most applications, but you may need to clean more frequently in high-traffic or heavily used areas. In summary, cleaning and maintaining stainless steel sheets involves gentle scrubbing with mild dish soap or stainless steel cleaner, rinsing with warm water, and thorough drying. By following these steps and avoiding abrasive materials, your stainless steel sheets will stay clean, shiny, and looking their best for years to come.

- Q: What are the different types of stainless steel sheet edges available?

- There are several different types of stainless steel sheet edges available, each offering its own unique advantages and characteristics. 1. Mill Edge: This is the standard edge finish produced during the manufacturing process. It has a straight, sharp edge with no additional treatment or finishing. Mill edge stainless steel sheets are commonly used in industrial applications where aesthetics are not a priority. 2. Slit Edge: Slit edge stainless steel sheets are created by cutting the sheet along its length, resulting in a slightly rounded edge. This type of edge is commonly used in applications where safety is a concern, as it reduces the risk of sharp edges causing injury. 3. Sheared Edge: Sheared edge stainless steel sheets are created by cutting the sheet along its width using shearing blades. This process produces a clean, straight edge without any additional finishing. Sheared edge sheets are often used in applications where precise dimensions are required. 4. Deburred Edge: Deburred edge stainless steel sheets have gone through a process to remove any sharp or rough edges, resulting in a smooth and safe edge finish. Deburring is often done using abrasive materials or specialized machinery. These sheets are commonly used in applications where safety and aesthetic appearance are both important. 5. Rolled Edge: Rolled edge stainless steel sheets have a curved or rounded edge, created by rolling the sheet during the manufacturing process. This edge type is commonly used in applications where a smoother, more finished appearance is desired. Rolled edge sheets are also easier to handle and less likely to cause injury during installation. Overall, the choice of stainless steel sheet edge depends on the specific requirements of the application, including safety concerns, aesthetic preferences, and dimensional accuracy.

- Q: Can stainless steel sheets be used for medical implants or devices?

- Yes, stainless steel sheets can be used for medical implants or devices. Stainless steel is a common material used for medical implants and devices due to its excellent corrosion resistance, strength, and biocompatibility. It is often used for applications such as orthopedic implants (like hip replacements and bone plates), surgical instruments, dental implants, and cardiovascular devices. Stainless steel sheets can be precisely fabricated into the desired shape and size for various medical applications, ensuring durability and long-term functionality. Additionally, stainless steel can be easily sterilized, making it suitable for use in medical environments.

- Q: Can stainless steel sheets be used in food processing?

- Yes, stainless steel sheets are commonly used in food processing due to their hygienic properties, resistance to corrosion, and ease of cleaning, making them suitable for contact with food and ensuring food safety.

- Q: What are the different types of stainless steel sheet surface patterns available?

- Some common types of stainless steel sheet surface patterns include brushed, mirror, embossed, diamond, and satin.

- Q: What are the different types of stainless steel sheet finishes?

- There are several different types of stainless steel sheet finishes available, each with its own unique characteristics and appearance. Some of the most common finishes include: 1. No.1 Finish: This is the most basic and widely used finish, also known as "hot rolled annealed and pickled" (HRAP). It has a dull, rough surface with visible grain lines. 2. No.2B Finish: This finish is achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It has a smooth, reflective surface with a slight haze. 3. No.2D Finish: Similar to No.2B, this finish is achieved by cold rolling and annealing. However, it has a slightly rougher surface and is commonly used for applications that do not require a highly reflective finish. 4. No.3 Finish: This finish is achieved by polishing the stainless steel sheet with abrasive belts or brushes. It has a semi-reflective surface with a grainy appearance. 5. No.4 Finish: Also known as "brushed finish," this is achieved by using fine abrasive belts or brushes to create a consistent, linear grain pattern on the surface. It has a matte appearance and is commonly used in architectural and decorative applications. 6. No.6 Finish: This finish is achieved by further polishing the stainless steel with finer abrasives, resulting in a smoother and more reflective surface. 7. No.7 Finish: Similar to No.6, this finish is achieved by using even finer abrasives, resulting in a highly reflective surface with a mirror-like appearance. 8. No.8 Finish: Also known as "mirror finish," this is the highest level of polish achievable on stainless steel. It has a flawless, reflective surface that is often used in decorative and high-end applications. In addition to these standard finishes, there are also specialized finishes available, such as embossed, patterned, or colored finishes, which can further enhance the aesthetic appeal of stainless steel sheets. The choice of finish depends on the specific application and desired appearance, with each finish offering its own unique advantages and characteristics.

- Q: What are the different types of mirror finishes available for stainless steel sheets?

- There are several types of mirror finishes available for stainless steel sheets, including #8 mirror, 2B mirror, and 4 mirror.

Send your message to us

Stainless Steel Hot Rolled Sheet And Slab And Plates Stocks

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords