Stainless Steel Plate Cold Rolled And Hot Rolled Stocks

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled AND HOT ROLLED aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

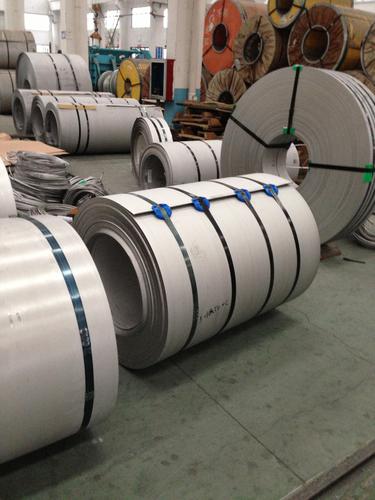

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, BANGLADESH, SRI LANKA, VIETNAM,

INDONEVISA, ETC.

SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, SS SHEET,PPGI,GI.

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the different types of stainless steel sheet edges?

- The different types of stainless steel sheet edges include mill edge, slit edge, deburred edge, rounded edge, and beveled edge.

- Q: Stainless steel plate glued to tiles, what glue?

- Depending on the size of the material and the number of adhesive areas, you can choose a different glue, the same function of glue, you should compare the quality and price of glue. Before you recommend what glue to use, you should first identify the following questions to choose the right glue.

- Q: Are stainless steel sheets resistant to impact?

- Stainless steel sheets possess a general resistance to impact. Renowned for their robustness and durability, stainless steel is capable of enduring substantial force without deformation or fracture. This quality renders stainless steel sheets highly sought after in the construction, automotive, and aerospace sectors, where impact resistance is imperative. Moreover, the impact resistance of stainless steel sheets can be augmented by subjecting them to additional hardening or tempering processes, tailored to meet the precise demands of the application at hand.

- Q: Are stainless steel sheets suitable for food storage containers?

- Yes, stainless steel sheets are highly suitable for food storage containers. Stainless steel is a durable and non-reactive material that does not leach harmful chemicals into food. It is resistant to corrosion, easy to clean, and can maintain the freshness and quality of stored food for extended periods. Additionally, stainless steel is non-porous, preventing the absorption of odors or flavors.

- Q: Are stainless steel sheets suitable for chemical storage tanks?

- Yes, stainless steel sheets are suitable for chemical storage tanks. Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for storing various chemicals. It is resistant to many corrosive substances, including acids, alkalis, and solvents, which are commonly stored in chemical storage tanks. Stainless steel sheets also have a high strength-to-weight ratio, allowing for the construction of tanks that can withstand the pressure and weight of the chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storing chemicals. Overall, stainless steel sheets are a reliable and suitable material for chemical storage tanks.

- Q: How do I prevent corrosion under insulation on stainless steel sheets?

- To prevent corrosion under insulation on stainless steel sheets, it is essential to ensure proper installation and maintenance. Firstly, use high-quality insulation materials that are resistant to moisture and have a vapor barrier to prevent any water penetration. Secondly, ensure that the stainless steel sheets are installed correctly, with no gaps or exposed areas that could allow moisture accumulation. Regular inspections and maintenance, including repairing damaged insulation or sealing any gaps, are crucial to prevent moisture ingress. Additionally, applying a suitable corrosion inhibitor on the stainless steel surface can provide an extra layer of protection.

- Q: How do I prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, there are a few measures you can take: 1. Regular cleaning: Stainless steel sheets should be cleaned regularly using mild soap or a stainless steel cleaner. Avoid using abrasive cleaners or scrubbing brushes, as they can scratch the surface and make it more prone to discoloration. 2. Avoid harsh chemicals: Avoid using harsh chemicals, bleach, or chlorine-based cleaners on stainless steel sheets, as they can cause discoloration. If any spills occur, clean them immediately to prevent staining. 3. Proper ventilation: Ensure proper ventilation in the area where stainless steel sheets are installed. This is especially important in areas where chemicals or fumes are present, as they can react with stainless steel and cause discoloration. 4. Protective coatings: Applying a protective coating to stainless steel sheets can help prevent discoloration. There are various protective coatings available in the market designed specifically for stainless steel. These coatings create a barrier between the steel and external factors, reducing the chances of discoloration. 5. Regular maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Address any issues promptly to prevent further deterioration. By following these preventative measures, you can minimize the risk of discoloration on stainless steel sheets and maintain their aesthetic appeal for a longer period.

- Q: What are the advantages of using stainless steel sheets in the medical industry?

- There are several advantages of using stainless steel sheets in the medical industry: 1. Hygiene and Cleanliness: Stainless steel is a non-porous material, which makes it easy to clean and disinfect. It is resistant to bacteria, mold, and other pathogens, making it an ideal choice for medical equipment, surgical instruments, and even hospital furniture. 2. Durability and Longevity: Stainless steel is highly durable and can withstand harsh conditions, including high temperatures, humidity, and corrosive substances. This ensures that medical equipment and instruments made from stainless steel sheets have a longer lifespan, reducing the need for frequent replacements. 3. Strength and Safety: Stainless steel sheets offer excellent strength and structural integrity, making them suitable for applications that require resistance to impact and pressure. This is crucial in the medical industry, where instruments and equipment undergo constant use and handling. 4. Resistance to Stains and Corrosion: Stainless steel is highly resistant to stains and corrosion, even in aggressive environments. This property is essential in medical facilities where exposure to various chemicals and liquids is common. The resistance to corrosion ensures that stainless steel sheets remain intact and do not release harmful substances into the environment. 5. Aesthetic Appeal: Stainless steel sheets have a sleek and modern appearance that adds to the overall aesthetic appeal of medical equipment and instruments. This can create a positive impression on patients, instilling confidence in the quality and cleanliness of the medical facility. 6. Recyclability: Stainless steel is a sustainable material as it can be recycled without any loss in quality. This reduces the environmental impact of the medical industry by minimizing waste and conserving resources. In conclusion, the advantages of using stainless steel sheets in the medical industry include hygiene, durability, strength, resistance to stains and corrosion, aesthetic appeal, and recyclability. These qualities make stainless steel a reliable and cost-effective choice for medical equipment, instruments, and other applications in healthcare settings.

- Q: Can stainless steel sheets be used for aerospace fasteners?

- Aerospace fasteners can indeed utilize stainless steel sheets. The reason for stainless steel's popularity in aerospace applications lies in its exceptional resistance to corrosion, impressive strength, and long-lasting nature. This material can endure both extreme temperatures and challenging environments, rendering it suitable for aircraft components that face demanding conditions. By manipulating stainless steel sheets into various shapes and sizes, they can function as fasteners like screws, bolts, and rivets, providing a dependable and secure connection within aerospace structures. Furthermore, stainless steel's lack of magnetic properties proves advantageous in specific aerospace scenarios where reducing magnetic interference becomes crucial. All in all, stainless steel sheets represent a trustworthy and extensively employed choice for aerospace fasteners.

- Q: What's the difference between stainless steel 304 2B board and Ba board?

- BA 2B process is not the same, finished products are not the same.The BA plate is rolled with a work roll of roughness 0.006-0.008 and annealed in a vertical furnace. The surface is very mirror like;2B edge Miao made by using roughness of work rolls 0.2-0.28, commonly used in horizontal continuous annealing production, rough surface.

Send your message to us

Stainless Steel Plate Cold Rolled And Hot Rolled Stocks

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords