Stainless Steel ASTM A240m 201/304/316L Stainless Steel Coil for Kitchen Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

Technical Notes:

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

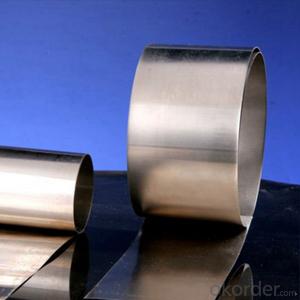

Detailed Picture for Stainless Steel Coils/Sheets:

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What are the different types of stainless steel sheet finishes for decorative purposes?

- There are several types of stainless steel sheet finishes commonly used for decorative purposes, including brushed, mirror, embossed, and patterned finishes.

- Q: How do you remove scratches from stainless steel sheets?

- To remove scratches from stainless steel sheets, there are a few methods you can try. First, you can start by using a non-abrasive cleaner or a mild detergent mixed with warm water. Apply the solution to the scratched area using a soft cloth or sponge, and gently rub in a circular motion. Rinse the area thoroughly and dry it with a clean cloth. If the scratches are still visible, you can try using a stainless steel scratch removal kit. These kits often contain a polishing compound specifically designed for stainless steel. Apply the compound to the scratched area and use a soft cloth to buff the surface in the direction of the grain. Continue buffing until the scratches are no longer visible. For deeper scratches, you may need to use a fine-grit sandpaper or a stainless steel scratch repair pen. Start by lightly sanding the scratched area in the direction of the grain. Be careful not to apply too much pressure, as this can damage the surface. After sanding, clean the area thoroughly and use a polishing compound to restore the shine. It's important to note that these methods may not completely remove deep scratches, and in some cases, a professional repair may be necessary. Additionally, always test any cleaning or repair method on a small, inconspicuous area before applying it to the entire surface to ensure it does not cause further damage.

- Q: What are the different types of stainless steel sheet finishes for marine applications?

- There are several types of stainless steel sheet finishes commonly used for marine applications, including 2B, #4, and #8 mirror finishes. 2B finish is a smooth, matte finish with good corrosion resistance, while #4 finish has a brushed appearance and is commonly used for aesthetic purposes. #8 mirror finish is highly reflective and provides a polished, mirror-like appearance, often preferred for its decorative appeal.

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The specific grade of stainless steel determines the maximum temperature that stainless steel sheets can endure. Typically, most stainless steel grades can handle temperatures up to approximately 1500°F (815°C) without significant oxidation or scaling. Nevertheless, some high-temperature stainless steel grades like 310 or 321 can endure temperatures up to 2100°F (1150°C) or even higher. To guarantee optimal performance and durability, it is crucial to consider the specific application and grade of stainless steel when determining its maximum temperature resistance.

- Q: How do I prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, it is important to keep them clean and dry. Avoid exposure to harsh chemicals or high chloride environments, as they can cause corrosion. Regularly inspect the sheets for any signs of damage or pitting, and promptly address any issues. Applying a protective coating or using stainless steel cleaners can also help to prevent pitting and maintain the appearance and integrity of the sheets.

- Q: What are the different types of stainless steel sheet grades available?

- There exists a range of stainless steel sheet grades, each possessing distinctive properties and applications. The following are some commonly used stainless steel sheet grades: 1. Austenitic stainless steel, such as 304 and 316, is widely utilized due to its outstanding corrosion resistance and high ductility. It lacks magnetic properties and can be easily formed and welded. 2. Ferritic stainless steel, including 430 and 409, exhibits magnetic properties and excellent corrosion resistance, particularly in high-temperature environments. Although less ductile than austenitic stainless steel, it offers good strength and formability. 3. Martensitic stainless steel, like 410 and 420, is characterized by its high strength, hardness, and wear resistance. It is commonly employed in applications where toughness and corrosion resistance are of lesser importance. 4. Duplex stainless steel, such as 2205 and 2507, is a combination of austenitic and ferritic stainless steels. It provides a unique blend of strength, corrosion resistance, and cost-effectiveness. This type is highly resistant to stress corrosion cracking and finds application in industries such as oil and gas, chemical processing, and marine applications. 5. Precipitation hardening stainless steel, represented by grades like 17-4 PH and 15-5 PH, is heat-treatable and offers high strength and corrosion resistance. It is commonly employed in aerospace and high-performance applications that necessitate a combination of strength and corrosion resistance. These are merely a few examples of the diverse stainless steel sheet grades available. Each grade possesses specific characteristics and is chosen based on desired properties and intended applications.

- Q: Are stainless steel sheets suitable for brewery equipment?

- Yes, stainless steel sheets are highly suitable for brewery equipment due to their excellent corrosion resistance, hygienic properties, and durability. Stainless steel is resistant to rust and corrosion caused by exposure to water, steam, and various chemicals commonly used in breweries. It can withstand high temperatures during brewing processes without degrading or affecting the taste of the final product. Additionally, stainless steel is easy to clean and maintain, ensuring the equipment remains sanitary and meets the strict hygiene standards required in the brewing industry.

- Q: What is the strain hardening exponent of stainless steel sheets?

- The strain hardening exponent of stainless steel sheets refers to the material's ability to increase its strength and hardness as it undergoes plastic deformation or strain. It is a measure of how the material's stress-strain curve changes with increasing deformation. Stainless steel sheets typically have a strain hardening exponent ranging between 0.2 and 0.4. This value indicates that the material exhibits a moderate increase in strength and hardness as it is subjected to plastic deformation. The higher the strain hardening exponent, the greater the material's ability to resist deformation and retain its shape under external forces. The strain hardening exponent is an important parameter in engineering applications as it affects the material's formability, ductility, and resistance to deformation. Higher values of the strain hardening exponent indicate a more work-hardening material, which is desirable in many industrial processes such as sheet metal forming or cold working. However, excessively high strain hardening exponents can lead to issues like cracking or material failure. It is important to note that the strain hardening exponent can vary depending on the specific grade and composition of the stainless steel alloy. Different stainless steel alloys may exhibit different strain hardening behaviors, so it is crucial to consider the specific material properties and specifications when determining the strain hardening exponent for a particular stainless steel sheet.

- Q: What is the maximum width of a stainless steel sheet?

- Typically, the maximum width of a stainless steel sheet relies on the manufacturing capabilities and equipment of the manufacturer. Nevertheless, a wide range of widths are generally offered by stainless steel sheet manufacturers to fulfill different industry and application requirements. Standard widths for these sheets can vary from 36 inches (91.44 cm) to 72 inches (182.88 cm) or possibly wider. Moreover, certain manufacturers may provide custom cutting services to accommodate specific customer needs for even larger widths. To ascertain the maximum width options for a desired stainless steel sheet, it is always recommended to consult the manufacturer or supplier.

- Q: Are stainless steel sheets good for high-temperature applications?

- Yes, stainless steel sheets are excellent for high-temperature applications due to their unique properties such as high heat resistance, corrosion resistance, and the ability to maintain their strength and integrity even at elevated temperatures.

Send your message to us

Stainless Steel ASTM A240m 201/304/316L Stainless Steel Coil for Kitchen Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords