Color Stainless Steel 201/304/316 Mirror Finish Stainless Steel Sheet For Elevators

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

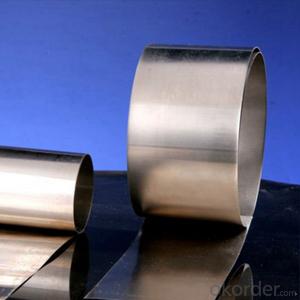

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

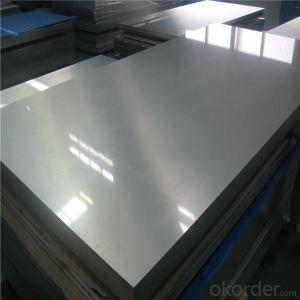

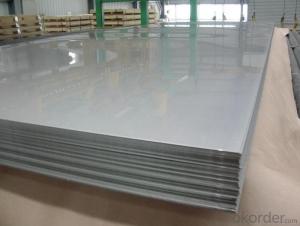

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: What are the different surface finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of surface finishes, each with its own unique characteristics and aesthetics. Let's explore some of the options available: 1. The No.1 Finish is the most commonly used finish for stainless steel sheets. It has a rough and dull appearance with visible grain lines. This finish is achieved through hot rolling and is suitable for applications where a rough finish is acceptable. 2. For a smooth and slightly dull surface, the No.2B Finish is ideal. It is obtained by cold rolling and annealing the stainless steel. This finish is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. Similar to the No.2B Finish, the No.2D Finish also involves cold rolling and annealing. However, it has a smoother and shinier appearance, making it suitable for applications that require a more polished look. 4. The No.3 Finish, also known as a brushed finish, is achieved by polishing the stainless steel with abrasive belts or brushes. It creates a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. If you desire a more refined and smoother appearance, the No.4 Finish is the way to go. This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than the No.3 Finish. It is commonly used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. For a highly reflective surface, the No.8 Finish, also known as a mirror finish, is perfect. This finish is achieved by continuously polishing the stainless steel with finer abrasive materials until a glossy, mirror-like appearance is obtained. It is ideal for architectural and decorative applications. 7. The Hairline Finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are just some of the most common surface finishes available for stainless steel sheets. The choice of finish will depend on the desired aesthetics, functionality, and application requirements.

- Q: 304 stainless steel plate surface quality inspection method which has several?

- 304 stainless steel surface quality of pickling process mainly depends on the heat treatment, surface oxidation Pihou formation if heat treatment before a process, or organization is not uniform, with acid does not improve the surface smoothness and uniformity. Therefore, attention should be paid to heat treatment or surface cleaning prior to heat treatment.

- Q: Can stainless steel sheets be used for electromagnetic shielding?

- Yes, stainless steel sheets can be used for electromagnetic shielding. Due to its high electrical conductivity and magnetic permeability, stainless steel can effectively block electromagnetic radiation and protect sensitive electronic devices from interference.

- Q: 304 stainless steel has several advantages, a few big advantages, the more concrete the better

- 304 stainless steel has excellent stainless steel corrosion resistance and better intergranular corrosion resistance. The oxidizing acid, in the experiments: the concentration of more than 65% of boiling temperature following nitrate, 304 stainless steel has high corrosion resistance. Alkaline solution and most organic acids and inorganic acids also have good corrosion resistance.

- Q: How are stainless steel sheets manufactured?

- Stainless steel sheets are manufactured through a multi-step process that involves several key stages. The production begins with the melting of raw materials, including iron ore, chromium, and nickel, in an electric arc furnace. This process helps to eliminate impurities and create a molten metal. Once the molten metal is obtained, it is cast into slabs or billets. These slabs are then hot rolled, which involves passing them through a series of rollers to reduce their thickness and increase their length. This initial rolling process also helps in refining the grain structure of the steel, making it more uniform. After hot rolling, the steel is pickled and annealed to remove any scale or impurities formed during the initial rolling process. Pickling involves immersing the steel in a bath of acid to remove the surface oxide layer, while annealing is a heat treatment process that helps to reduce internal stresses and improve the steel's ductility. Following pickling and annealing, the steel is cold rolled. Cold rolling involves passing the annealed steel through a set of rollers at room temperature to further reduce its thickness and improve its surface finish. This process also imparts the desired mechanical properties to the stainless steel sheets. Once the desired thickness is achieved through cold rolling, the stainless steel sheets are subjected to various finishing processes. These may include surface treatments like polishing, embossing, or etching to enhance the appearance and texture of the sheets. Additionally, the sheets can be cut to size using shearing or laser cutting techniques. Finally, the stainless steel sheets undergo quality control checks to ensure they meet the required specifications. This includes inspecting the dimensions, surface finish, and mechanical properties of the sheets. Once approved, the sheets are ready for packaging and distribution to various industries that utilize stainless steel in their applications. Overall, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, pickling, annealing, cold rolling, and finishing. This meticulous process ensures the production of high-quality stainless steel sheets that possess excellent corrosion resistance, strength, and aesthetic appeal.

- Q: What are stainless steel sheets?

- Stainless steel sheets are flat pieces of metal made from stainless steel, a type of alloy that contains chromium, nickel, and other elements. These sheets are highly versatile and widely used in various industries for their excellent corrosion resistance, durability, and aesthetic appeal. They are manufactured through a process called hot rolling or cold rolling, which involves passing the steel through a series of rollers to achieve the desired thickness and finish. Stainless steel sheets are commonly used for applications such as construction, automotive manufacturing, kitchenware, appliances, and architecture. They come in different grades, surface finishes, and sizes to cater to different requirements. Whether it's for decorative purposes or functional applications, stainless steel sheets offer a reliable and long-lasting solution.

- Q: What is the formability of stainless steel sheets?

- The formability of stainless steel sheets is generally good, as they can be easily shaped, bent, and formed into various complex shapes without cracking or breaking.

- Q: What is the maximum length available for stainless steel sheets?

- The maximum length available for stainless steel sheets can vary depending on the manufacturer and supplier. However, it is common for stainless steel sheets to be available in lengths of up to 120 inches or 10 feet.

- Q: How do you determine the best thickness of stainless steel sheet for a specific application?

- To determine the best thickness of stainless steel sheet for a specific application, several factors need to be considered. These factors include the required strength, durability, and corrosion resistance for the application, as well as any weight or cost limitations. It is also crucial to analyze the mechanical and chemical properties of the stainless steel and evaluate its compatibility with the intended environment and potential stress factors. Engineering calculations, industry standards, and consultation with material experts or engineers can help in making an informed decision about the appropriate thickness for the stainless steel sheet.

- Q: Can stainless steel sheets be used for elevator wall panels?

- Elevator wall panels can indeed be constructed using stainless steel sheets. The utilization of stainless steel as a material for elevator interiors is highly favored due to its robustness, cleanliness, and aesthetic attractiveness. It imparts a sleek and contemporary appearance that enhances the overall look of the elevator. Furthermore, stainless steel is resistant to corrosion, staining, and scratching, rendering it suitable for high-traffic areas such as elevators. Moreover, it is effortless to clean and maintain, guaranteeing that the elevator walls remain in optimal condition for an extended period. What's more, stainless steel sheets can be tailored to meet specific design requirements and preferences, offering a plethora of finishes, patterns, and colors that can harmonize with the building or elevator's design. Ultimately, stainless steel sheets prove to be a superb option for elevator wall panels.

Send your message to us

Color Stainless Steel 201/304/316 Mirror Finish Stainless Steel Sheet For Elevators

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords