201/304/316L Stainless Steel Sheets Elevator Decorative Sheets Made In China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

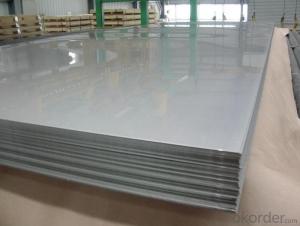

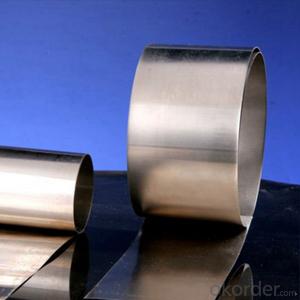

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

ITEM | DESCRIPTION |

Commodity | Stainless Steel Coil |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc. |

Surface | 2B, BA, 8K, No. 4 No.1 |

Standard | AISI, ASTM, DIN, EN, GB, JIS, etc. |

Specification | 1. Thickness : 0.3mm -120mm |

Application | 1. Automotive: Automotive trim and molding/Difficult-to-form exhaust-system |

Process | Hot rolled / cold rolled |

Payment | L/C,T/T |

MOQ | 20 Ton |

Productivity | 700 tons per month. |

Package | Standard seaworthy export packing or according to the customers' request. |

Delivery Time | It is based on the order, normally within 30 days after receiving your advance payment. |

Note | We can produce other standard as the customers' requirement. |

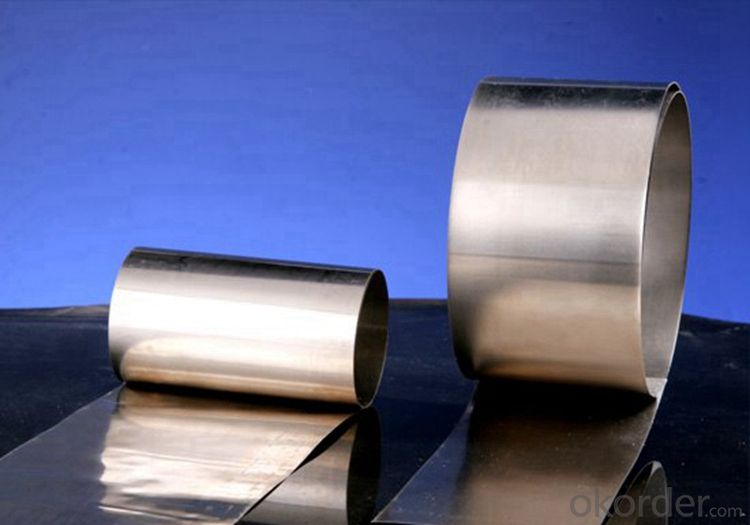

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be used for solar water heaters?

- Yes, stainless steel sheets can be used for solar water heaters. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of solar water heating systems. It ensures longevity and reliable performance in capturing and transferring solar energy to heat water efficiently.

- Q: Are stainless steel sheets heat resistant?

- Indeed, stainless steel sheets exhibit exceptional resistance to heat. Renowned for their ability to withstand high temperatures and corrosion, stainless steel sheets are highly suitable for a wide range of applications. They maintain their structural integrity even under intense heat, without warping, melting, or compromising their integrity. This remarkable heat resistance can be attributed to the presence of chromium in stainless steel, which forms a protective oxide layer on the surface, preventing oxidation and preserving its strength at elevated temperatures. Consequently, stainless steel sheets are extensively utilized in vital industries like manufacturing, construction, automotive, and food processing, where the ability to withstand heat is paramount.

- Q: Are stainless steel sheets good for pressure piping?

- Yes, stainless steel sheets are excellent for pressure piping due to their high strength, corrosion resistance, and ability to withstand extreme temperatures.

- Q: How do I remove stains or marks from stainless steel sheets?

- To effectively eliminate stains or marks on stainless steel sheets, a few simple steps can be taken: 1. Initiate the process by cleansing the stainless steel surface with warm water and a mild detergent or dish soap. Take a soft cloth or sponge and gently scrub the affected area. Rinse thoroughly with clean water and dry with a towel. 2. If the stain persists, the utilization of white vinegar can be attempted. Dampen a cloth or sponge with vinegar and gently rub the stained area. The acidic properties of vinegar aid in breaking down the stains. Rinse the surface with water and dry it completely. 3. In the case of more stubborn stains or marks, a paste can be concocted using baking soda and water. Apply the paste to the affected area and gently rub it in using a soft cloth or sponge. Allow it to sit for a few minutes, then rinse with water and dry thoroughly. 4. Should the aforementioned methods prove ineffective, resorting to a stainless steel cleaner specifically designed for stain or mark removal is advisable. Adhere to the instructions on the cleaner's packaging for optimal results. Remember to rinse the surface thoroughly and ensure complete drying after employing a commercial cleaner. 5. It is essential to refrain from using abrasive cleaners, steel wool, or harsh chemicals on stainless steel sheets, as they possess the potential to scratch or damage the surface. Additionally, it is recommended to always test any cleaning method or product on a small, inconspicuous area before applying it to the entire surface. By adhering to these steps and utilizing appropriate cleaning methods, stains or marks can be effectively eradicated from stainless steel sheets, thereby restoring their original shine and appearance.

- Q: Are stainless steel sheets suitable for automotive grilles or trim?

- Yes, stainless steel sheets are highly suitable for automotive grilles or trim. Stainless steel is a durable and corrosion-resistant material that can withstand the harsh conditions of the automotive environment, including exposure to moisture, road salt, and varying temperatures. It is also known for its strength and can provide excellent protection to the vehicle's front end. Moreover, stainless steel sheets can be easily formed and molded into various shapes and designs to meet the specific styling requirements of automotive grilles or trim. Additionally, stainless steel has an attractive aesthetic appeal that can enhance the overall look of the vehicle. Overall, the use of stainless steel sheets for automotive grilles or trim ensures longevity, functionality, and a polished appearance.

- Q: What is the electrical resistivity of stainless steel sheets?

- The electrical resistivity of stainless steel sheets typically ranges from 70 to 80 micro-ohm centimeters (µΩ·cm).

- Q: Can stainless steel sheets be used for architectural wire mesh?

- Architectural wire mesh can indeed be made from stainless steel sheets. This material is highly versatile and widely used in architecture because of its durability, attractive appearance, and resistance to corrosion. By transforming stainless steel into sheets, it becomes easily manipulable and can be woven into wire mesh panels suitable for various architectural purposes, including building facades, interior partitions, sunscreens, and balustrades. The use of stainless steel sheets for architectural wire mesh allows for the creation of intricate and visually appealing designs, while also providing strength, stability, and longevity to the structure. Furthermore, customization options are available for stainless steel wire mesh, including mesh size, wire diameter, and finish, ensuring that it meets the specific requirements of each architectural project.

- Q: Can stainless steel sheets be used for kitchen backsplashes?

- Indeed, kitchen backsplashes can utilize stainless steel sheets. The durability, heat and moisture resistance, and effortless upkeep of stainless steel make it a favored option for kitchen backsplashes. Not only does it lend a sleek and contemporary appearance to the kitchen, but it also shields the wall from unsightly splatters and stains. Moreover, stainless steel sheets come in a range of finishes, including brushed, mirrored, or patterned, giving homeowners the freedom to select the style that perfectly complements their kitchen design.

- Q: What are the different types of perforated finishes available for stainless steel sheets?

- There are several different types of perforated finishes available for stainless steel sheets, each offering a unique look and functionality. 1. Round Hole: This is the most common type of perforated finish for stainless steel sheets. It features evenly spaced round holes that provide a modern and clean aesthetic. 2. Square Hole: Similar to the round hole finish, square holes are evenly spaced but have a square shape. This finish is often chosen for its simple yet distinctive appearance. 3. Slotted Hole: Slotted hole perforated finishes have elongated holes, which can be either straight or staggered. This type of finish is often preferred for its decorative appeal and ability to provide excellent ventilation. 4. Hexagonal Hole: Hexagonal hole perforated finishes have six-sided holes, offering a visually appealing and unique pattern. This finish is commonly used in architectural applications to create a modern and eye-catching design. 5. Decorative Patterns: In addition to the standard hole shapes mentioned above, stainless steel sheets can also be perforated with various decorative patterns. These patterns can include floral designs, abstract shapes, or custom designs, allowing for a truly unique and personalized finish. It is important to note that the choice of perforated finish depends on the intended use of the stainless steel sheet. Factors such as the desired appearance, functional requirements (such as ventilation or filtration), and the specific application will all influence the selection of the appropriate perforated finish for stainless steel sheets.

- Q: Can stainless steel sheets be polished?

- Stainless steel sheets, indeed, possess the ability to undergo polishing. The act of polishing these sheets serves the purpose of enhancing their visual appeal, resulting in the creation of a sleek and lustrous surface. This procedure typically entails the utilization of abrasive substances like sandpaper, polishing compounds, or specialized machinery in order to eliminate any flaws or marks present on the stainless steel sheet's surface. This task can be accomplished both manually or with the assistance of specific equipment. By polishing stainless steel sheets, not only does their aesthetic allure become enhanced, but their susceptibility to corrosion and staining is also significantly reduced.

Send your message to us

201/304/316L Stainless Steel Sheets Elevator Decorative Sheets Made In China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords