Square Billets for construction Hot Sale Deformed Billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Square Billets for construction Hot Sale Deformed Billet

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Square Billets for construction Hot Sale Deformed Billet

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Square Billets for construction Hot Sale Deformed Billet

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Square Billets for construction Hot Sale Deformed Billet

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

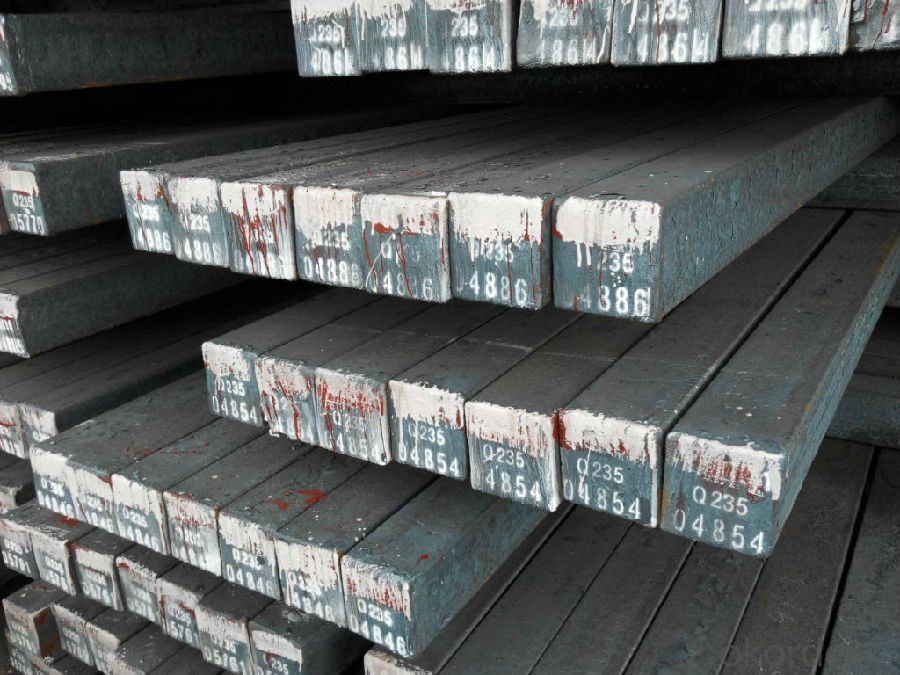

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can steel billets be used for making sculptures?

- Yes, steel billets can be used for making sculptures. Steel is a versatile material that offers strength, durability, and the ability to be shaped and molded into various forms. Many artists have embraced steel as a medium for creating sculptures due to its modern aesthetic and its ability to withstand outdoor conditions. By heating, cutting, and welding the steel billets, artists can transform them into unique and imaginative sculptures.

- Q: How are steel billets used in the manufacturing of pressure vessels?

- Steel billets are used in the manufacturing of pressure vessels as they serve as the raw material for shaping and forming various components such as plates, shells, and heads. These billets are heated and then hot rolled or forged into the desired shape, providing the necessary strength and durability required for pressure vessel construction.

- Q: Billet heating furnace prices?

- Look at the video case, you can consult the advisory.

- Q: Refinery carbon 3 is propane, then carbon four carbon five is what name ah?.What are they used for?

- Carbon four is butane, which is made up of four carbon, divided into n-butane and isobutane.Carbon five is pentane, composed of five carbon, divided into pentane, isoamyl, and new pentane.A product of petroleum refining, usually consisting of alkanes with a greater number of carbon atoms.

- Q: What are the advantages of using steel billets in the manufacturing process?

- Using steel billets in the manufacturing process offers numerous benefits. Firstly, the controlled casting process used to produce steel billets ensures superior quality and consistent material. This consistency is essential in manufacturing applications that demand precise dimensions and mechanical properties. Secondly, steel billets possess remarkable strength and durability, making them suitable for a wide range of manufacturing purposes. Steel is renowned for its high tensile strength, enabling it to withstand heavy loads and impacts without any deformation or failure. As a result, steel billets are ideal for structural components and machinery parts that must endure high levels of stress. Moreover, steel billets can be easily shaped and formed into various sizes and shapes to meet specific design requirements. Manufacturers can achieve the desired shape by hot rolling, cold rolling, or forging the billets. This flexibility allows for the creation of intricate and complex parts with ease. Additionally, steel billets have exceptional resistance to heat and corrosion. This makes them highly suitable for applications involving high temperatures or exposure to harsh environments, such as automotive components, construction materials, and industrial machinery. Furthermore, steel billets are readily available and cost-effective compared to alternative materials. Steel is one of the most widely produced and recycled materials globally, ensuring a consistent supply and competitive prices. This availability and affordability make steel billets the preferred choice for many manufacturers. Lastly, steel billets are environmentally friendly. The recyclability of steel helps reduce energy consumption and greenhouse gas emissions during the manufacturing process. Choosing steel billets enables businesses to minimize their environmental impact and make sustainable choices. In conclusion, the advantages of using steel billets in the manufacturing process include their superior quality and consistency, exceptional strength and durability, versatility in shaping, resistance to heat and corrosion, availability and cost-effectiveness, and environmental sustainability.

- Q: Can steel billets be used for making hand tools?

- Hand tools can be made using steel billets. Steel billets are semi-finished steel products that are commonly used for further processing and shaping into different forms. Steel billets can be used to manufacture various hand tools such as wrenches, pliers, hammers, screwdrivers, and many others. Steel is a popular choice for manufacturing hand tools because of its strength, durability, and resistance to wear and tear. Steel billets can be forged, machined, or heat-treated to achieve the desired shape, size, and hardness required for hand tools. The versatility of steel allows it to be easily molded into different tool designs, providing the necessary strength and functionality. Moreover, steel hand tools offer several advantages over tools made from other materials. The high tensile strength of steel ensures that the tools can withstand significant force and pressure without breaking or deforming. Additionally, steel tools are resistant to corrosion and rust, making them suitable for both indoor and outdoor use, even in harsh environments. In conclusion, steel billets are indeed suitable for manufacturing hand tools. The strength, durability, and versatility of steel make it an excellent material for producing a wide range of hand tools that can endure heavy usage and provide long-lasting performance.

- Q: What is the role of steel billets in the manufacturing of fasteners?

- Steel billets play a crucial role in the manufacturing of fasteners. Fasteners are essential components used to join two or more objects together, providing stability and strength. Steel billets, being semi-finished products, are the starting point for producing fasteners. The first step in the manufacturing process is to heat the steel billets to a specific temperature, typically around 1200-1300 degrees Celsius, to make them malleable. Heating the billets allows for easier shaping and manipulation during subsequent processes. Once the billets are heated, they are then passed through a series of dies, which exert tremendous pressure to shape them into the desired fastener form. The dies are designed with the specific dimensions and shape required for the particular type of fastener being produced, such as bolts, screws, or nuts. During the shaping process, the steel billets undergo deformation and compression, resulting in the formation of the fastener's basic structure and form. The pressure applied by the dies ensures that the fasteners have the necessary strength and durability to sustain the forces they will encounter when used for their intended applications. Furthermore, steel billets are chosen for fastener manufacturing due to their inherent properties. Steel is known for its exceptional strength, toughness, and resistance to corrosion, making it an ideal material for fasteners. By starting with high-quality steel billets, the resulting fasteners will possess these desirable attributes, ensuring their reliability and longevity once installed. In summary, steel billets are instrumental in the production of fasteners. They serve as the raw material that undergoes shaping and deformation to ultimately form the desired fastener shape. The use of steel billets ensures that the resulting fasteners possess the necessary strength, durability, and corrosion resistance required for their intended applications.

- Q: What are the main differences between carbon steel and alloy steel billets?

- Carbon steel and alloy steel billets are both types of steel used in various industries, but they have some key differences. The main difference between carbon steel and alloy steel billets lies in their composition. Carbon steel billets are primarily made up of iron and carbon, with carbon content usually ranging from 0.05% to 2.1%. This makes carbon steel relatively more affordable and easier to produce compared to alloy steel. On the other hand, alloy steel billets contain additional elements like manganese, nickel, chromium, and molybdenum, which are added to enhance specific properties of the steel. These alloying elements give alloy steel superior strength, hardness, and resistance to corrosion compared to carbon steel. Another major difference between carbon steel and alloy steel billets is their mechanical properties. Carbon steel billets are generally known for their high ductility and ability to be easily shaped or formed, making them suitable for applications that require flexibility and easy machinability. Alloy steel billets, on the other hand, have higher tensile strength, toughness, and wear resistance due to the presence of alloying elements. This makes alloy steel billets ideal for applications that require high strength and resistance to wear, such as in construction, automotive, and aerospace industries. Furthermore, the heat treatment process for carbon steel and alloy steel billets also differs. Carbon steel billets are often heat-treated to improve their hardness and strength, with common treatments including quenching and tempering. Alloy steel billets, on the other hand, can undergo a wider range of heat treatment processes, including annealing, normalizing, and precipitation hardening. These heat treatments help to optimize the properties of alloy steel billets for specific applications, such as increasing strength or improving machinability. In summary, the main differences between carbon steel and alloy steel billets lie in their composition, mechanical properties, and heat treatment processes. Carbon steel is primarily made up of iron and carbon, while alloy steel contains additional alloying elements. Carbon steel has high ductility and is easily shaped, while alloy steel has superior strength, hardness, and resistance to corrosion. The heat treatment processes for these two types of steel also differ, with alloy steel having a wider range of treatment options.

- Q: What is the typical length of a steel billet?

- The typical length of a steel billet can vary depending on several factors such as the intended use, production process, and specific industry standards. However, in general, steel billets are commonly produced in lengths ranging from 2 to 12 meters (6.5 to 40 feet). These lengths are commonly used for further processing, such as hot rolling or forging, to create various steel products like bars, rods, beams, or other structural components. It is important to note that the actual length of a steel billet can be tailored to meet the specific requirements of a particular application or customer order.

- Q: What is the role of steel billets in the production of valves and fittings?

- Valves and fittings, which are crucial in industries like oil and gas, petrochemical, and water treatment, rely heavily on steel billets. These billets, derived from molten steel, serve as the starting point for producing these components. To meet specific requirements, the billets are cast into shapes like round, square, or rectangular. The usage of steel billets enables manufacturers to maintain consistent quality and performance in valves and fittings. The selection process involves considering factors such as chemical composition, mechanical properties, and microstructure to guarantee the desired characteristics in the end product. After obtaining the steel billets, they undergo various manufacturing processes like forging, machining, and heat treatment. These processes further enhance the strength, integrity, and functionality of the final valve and fitting components. One of the advantages of steel billets is their versatility in customization. They can be easily cut, shaped, and formed to create valves and fittings with different sizes, configurations, and designs. This flexibility allows them to meet the specific requirements of different applications and industries. In summary, steel billets serve as the raw material for valves and fittings, playing a vital role in their production. Their strength, durability, and customization capabilities ensure the reliability and performance of these components in various industrial settings.

Send your message to us

Square Billets for construction Hot Sale Deformed Billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords