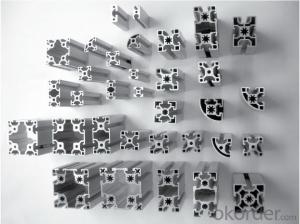

Special Aluminum Profiles - Customized 6063 Alu Profile Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: How do aluminum profiles contribute to energy-efficient lighting systems?

- Enhancing the energy efficiency of lighting systems is a significant role played by aluminum profiles. The lightweight and highly conductive nature of aluminum allows for efficient heat dissipation, which is crucial in maintaining the lifespan and efficiency of bulbs. By utilizing aluminum profiles, the generated heat from the light source can be effectively transferred away, ensuring optimal performance and longevity. Additionally, aluminum profiles offer versatility and the ability to accommodate various lighting components such as LED strips or bulbs, reflectors, and lenses. These profiles provide a stable and secure housing for these components, preventing any damage or misalignment that could affect the efficiency of the lighting system. Furthermore, precision engineering in aluminum profiles makes installation and maintenance easy, further contributing to the overall energy efficiency of the system. Another significant advantage of aluminum profiles is their capability to act as a heat sink. By diverting heat away from the light source, the profiles help maintain lower operating temperatures, resulting in reduced energy consumption and increased efficiency of the lighting system. This is especially important for LED lighting, as they are sensitive to heat and can experience a decline in light output if not adequately cooled. Aluminum profiles enable efficient thermal management, ensuring that LED lights operate at their optimum level, saving energy and reducing the need for frequent replacements. Moreover, aluminum is a recyclable material, making it an environmentally friendly choice for lighting systems. The usage of aluminum profiles promotes sustainable practices by reducing the demand for raw materials and minimizing waste. This aligns with the principles of energy efficiency and conservation, as it reduces the overall carbon footprint of the lighting system. In summary, aluminum profiles contribute to energy-efficient lighting systems by facilitating effective heat dissipation, providing a stable housing for lighting components, acting as a heat sink, and promoting sustainable practices. These profiles enhance the performance, lifespan, and energy efficiency of lighting systems, making them an essential component in modern lighting solutions.

- Q: Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can be used for modular storage systems. Aluminum is a lightweight and durable material that is commonly used in various industries, including storage and shelving systems. Its versatility allows for easy customization and the ability to create modular units that can be easily assembled, disassembled, and reconfigured as needed. Additionally, aluminum profiles provide a sleek and modern aesthetic to storage systems.

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a specific project.

- <p>To calculate the amount of aluminum profiles needed for a project, first, determine the dimensions and design of the structure. Measure the length, width, and height of the required profiles. Consider the number of profiles needed for each section of the project. Multiply the length of each profile by the number of profiles required. Sum these totals for all sections to get the overall amount of aluminum needed. Factor in a margin for cutting and waste to ensure you have enough material. Consult with suppliers or use specialized software for more precise calculations, especially for complex projects.</p>

- Q: What are the different surface protection coatings for aluminum profiles?

- Some of the different surface protection coatings for aluminum profiles include anodizing, powder coating, painting, and electroplating. Anodizing forms a protective oxide layer on the surface, while powder coating and painting provide a durable and decorative finish. Electroplating involves depositing a thin layer of metal onto the surface to enhance its corrosion resistance.

- Q: This question asks for an overview of the various types of aluminum profiles that are utilized in the construction of interior partitions and ceilings.

- <p>Aluminum profiles for interior partitions and ceilings come in various types, each serving specific purposes and functions. Common types include: 1. U-Channel profiles, used for creating the framework of ceilings and partitions. 2. T-profiles, often used as a cover for the joints between panels. 3. H-profiles, which are used as main beams in ceiling systems. 4. Angle profiles, used for corner connections and support. 5. Flat bar profiles, used for decorative or functional purposes in ceilings and partitions. 6. Box profiles, which can be used for both structural and aesthetic applications. 7. Special profiles, designed for specific applications such as lighting fixtures or air conditioning ducts. These profiles are chosen based on the design requirements, load-bearing needs, and aesthetic preferences for the project.</p>

- Q: Are aluminum profiles suitable for indoor applications with high humidity?

- Yes, aluminum profiles are suitable for indoor applications with high humidity. Aluminum is highly resistant to corrosion and does not rust, making it an ideal material for humid environments. Additionally, aluminum profiles can withstand moisture and humidity without warping or deteriorating, ensuring their durability and suitability for such conditions.

- Q: Can aluminum profiles be used in the construction of solar panels?

- Solar panels can indeed incorporate aluminum profiles in their construction. Aluminum, a lightweight and durable material, finds widespread use across industries, including construction and solar energy, due to its numerous advantages. To begin with, aluminum profiles offer structural support and stability to solar panel systems. They can be easily molded into various shapes, enabling flexibility during panel assembly. Moreover, aluminum boasts exceptional corrosion resistance, guaranteeing the panels' longevity and durability in diverse weather conditions. In addition, aluminum profiles possess high conductivity, a crucial factor for the efficient operation of solar panels. By effectively dissipating heat produced by the solar cells, they prevent overheating and amplify the panels' overall performance and lifespan. Furthermore, aluminum stands as a sustainable and environmentally-friendly material. Its easy recyclability and reusability significantly decrease the environmental impact of solar panel production. This aligns with the principles of renewable energy and sustainability, making aluminum profiles the preferred choice in solar panel construction. In conclusion, the utilization of aluminum profiles in solar panel construction is a practical and efficient choice due to their structural strength, resistance to corrosion, thermal conductivity, and sustainability. By incorporating aluminum profiles, solar panel systems can ensure reliability, efficiency, and environmental friendliness.

- Q: This question asks if aluminum profiles can be utilized for constructing exterior walls or facades.

- <p>Yes, aluminum profiles can be used for exterior walls or facades. They are known for their durability, low maintenance, and resistance to weather conditions. Aluminum is lightweight, strong, and can be easily shaped into various designs, making it an ideal material for modern architecture. It also offers excellent thermal performance and can be combined with insulation to enhance energy efficiency. Additionally, aluminum profiles can be powder-coated or anodized to provide a protective finish and a wide range of color options, enhancing the aesthetic appeal of the building facade.</p>

- Q: How is the price of aluminum profile calculated?

- Aluminum prices are generally in accordance with the aluminum ingot price plus processing fees to count. The aluminum market is unstable compared with other industries, especially the price is changing almost every day. Please take the same day price. Shandong Southwest Aluminum material

- Q: This question asks for the typical specifications and measurements of aluminum profiles that are used in the construction of building frames.

- <p>Aluminum profiles used in building frames come in various specifications and measurements. Commonly, they include I-beams, T-profiles, and C-channels with different thicknesses and dimensions. Sizes can range from 30mm to 200mm in width and from 1mm to 10mm in thickness. The length of these profiles can vary, but they are often available in standard lengths such as 6 meters. Specific dimensions and tolerances are determined by the building's design requirements, load-bearing needs, and manufacturing standards. It's also important to consider the alloy type, which can affect strength and corrosion resistance. Always consult with an engineer or supplier for the exact specifications suitable for a particular project.</p>

Send your message to us

Special Aluminum Profiles - Customized 6063 Alu Profile Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords