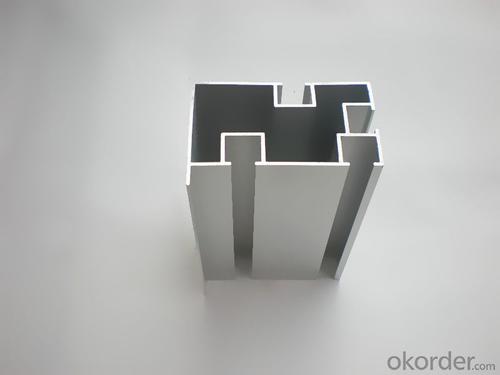

Custom Extruded Aluminum Profiles 6061 Alu Profile Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Can someone give me a direction? Thank you

- Guangdong now has a lot of aluminum factory, and the price is very low

- Q: Can aluminum profiles be used for solar panel installations?

- Solar panel installations can make use of aluminum profiles, which are frequently employed in the construction industry because of their lightweight nature, durability, and resistance to corrosion. These attributes make aluminum an optimal material for supporting and securing solar panels. Aluminum profiles can be easily customized and fabricated to meet specific installation requirements, including roof or ground mounting systems. Furthermore, aluminum possesses exceptional thermal conductivity, enabling efficient dissipation of heat from the solar panels. This characteristic is vital for maintaining their performance and lifespan. In addition, aluminum profiles are commonly utilized to frame solar panels, providing structural support and ensuring stability in diverse weather conditions. All in all, aluminum profiles are a favored option for solar panel installations due to their robustness, longevity, and adaptability.

- Q: How do aluminum profiles handle extreme weather conditions?

- Aluminum profiles are known for their exceptional durability and resilience, making them highly capable of handling extreme weather conditions. Due to their inherent corrosion resistance, aluminum profiles can withstand harsh weather elements such as heavy rain, snow, extreme temperature fluctuations, and even high levels of UV radiation without corroding or deteriorating. One of the key attributes of aluminum is its ability to create a protective oxide layer on its surface, known as aluminum oxide. This layer acts as a natural barrier, shielding the metal from moisture, salt, and other corrosive agents present in the atmosphere. As a result, aluminum profiles remain unaffected by rain or snow, and they do not rust or corrode like other metals. Furthermore, aluminum's thermal conductivity allows it to quickly dissipate heat, preventing any damage caused by extreme temperature variations. Whether exposed to scorching heat or freezing cold, aluminum profiles expand and contract minimally, which helps maintain their structural integrity and prevents warping or cracking. Moreover, aluminum profiles can withstand high wind loads, making them suitable for areas prone to hurricanes, tornadoes, or strong gusts. Their lightweight yet sturdy nature enables them to withstand significant pressure without bending or breaking. In terms of UV radiation, aluminum profiles have excellent resistance to fading and discoloration. They can effectively endure prolonged exposure to sunlight without losing their original color or surface finish. This makes them an ideal choice for outdoor applications, such as windows, doors, and facades, where they remain visually appealing and structurally sound even in extreme weather conditions. Overall, aluminum profiles exhibit remarkable durability, corrosion resistance, thermal stability, and resistance to UV radiation, allowing them to effectively handle and withstand the challenges posed by extreme weather conditions.

- Q: Can aluminum profiles be used in lightweight construction applications?

- Yes, aluminum profiles can definitely be used in lightweight construction applications. Aluminum is a lightweight and versatile material that offers numerous advantages in construction projects. It has a high strength-to-weight ratio, which means that structures can be built with less material without compromising on strength or durability. This makes it an ideal choice for lightweight construction applications, where reducing weight is a key consideration. Aluminum profiles are commonly used in various construction projects, such as building facades, interior partitions, roofing systems, and structural frameworks. They are particularly popular in industries like aerospace, automotive, and marine, where weight reduction is critical. Furthermore, aluminum profiles offer excellent corrosion resistance, making them suitable for outdoor and high-moisture environments. They are also highly malleable and can be easily fabricated into different shapes and sizes, allowing for customized designs and easy installation. Additionally, aluminum is an environmentally friendly material as it can be recycled indefinitely without losing its properties. In summary, aluminum profiles are widely used in lightweight construction applications due to their lightweight nature, strength, durability, corrosion resistance, malleability, and environmental benefits.

- Q: High compartment aluminum profiles are generally divided into several specifications, what are the attributes?

- Aluminum alloy profiles are basically no GB non-standard, but the state has special specifications for architectural aluminum profiles, mainly on the thickness of the material, materials and so on.Each aluminum alloy profiles manufacturing enterprises are basically similar products, but in specific structure of the discrepancy. But such as the more general series, such as GB 50, 868, and 90, these are basically the same.The 80 series and the 60 series refer to the aluminium alloy profiles with widths of 80 mm and 60 mm.

- Q: What are the methods to protect aluminum profiles from corrosion during the installation and usage phases?

- <p>To prevent corrosion of aluminum profiles during installation and use, follow these steps: 1. Choose high-quality aluminum profiles with proper alloy composition that resists corrosion. 2. Ensure the surface is clean and free from contaminants before installation. 3. Apply a protective coating such as a clear anodized finish, powder coating, or paint to the aluminum surface. 4. Avoid contact with corrosive substances like saltwater or chemicals. 5. Regularly inspect and clean the profiles to remove dirt and debris that can lead to corrosion. 6. Use stainless steel fasteners and avoid dissimilar metal contact, as it can accelerate corrosion. 7. Maintain a dry environment to prevent moisture-induced corrosion. By following these practices, you can significantly reduce the risk of corrosion and prolong the lifespan of aluminum profiles.</p>

- Q: Are aluminum profiles suitable for use in aerospace structural components?

- Yes, aluminum profiles are suitable for use in aerospace structural components. Aluminum is a lightweight and strong material, making it an ideal choice for aerospace applications where weight reduction is crucial. It offers high strength-to-weight ratio, excellent corrosion resistance, and good formability, allowing for the fabrication of complex shapes and structures. Additionally, aluminum profiles can be easily joined using various techniques such as welding, riveting, or adhesive bonding, making them versatile for the assembly of aerospace structural components. Overall, the combination of its properties and ease of manufacturing make aluminum profiles a suitable choice for use in aerospace structural components.

- Q: The side wall of the box body is a heat sink, and the exposed end of the heat radiating fin can not damage the surface, and the inner surface is made of four M3h6 internal thread nut columns, which is welded? Or press riveting? Heat sink is extruded aluminum profile, the thickness of 5.5mm, slotted deep 2.5mm, how should this process? Do you have this nut column?

- Because the strength of the aluminum profile is too small, it is not suitable for thread matching. It is necessary to use screw sleeve (or wire screw sleeve) to form internal thread, or to solve the problem of strength with rivet nut;If it is for the wall thickness, is used for riveting nuts with the tool is riveter, or the number of small batch, with a large amount of manual, can use pneumatic riveter considering.

- Q: What are the specific features of industrial aluminum profiles?

- Abrasion resistance, corrosion resistance, anti oil Department of Chongqing Lixing

- Q: RT: you! What are coated aluminum profiles? What's the surface treatment? What's the difference between grain transfer and wood grain transfer? Thank you first!!!

- Aluminum Alloy profiles the most common and most primitive (referred to as aluminum), is Aluminum Alloy itself color, silver white, but this state for a long time, Aluminum Alloy surface will be oxidized into a dark gray or black. In order to solve this problem, the most common practice in our country is to spray a layer of powder (high temperature treatment) on the surface, that is electrostatic powder spraying. Also, fluorocarbon electrophoresis processing processing, wood grain transfer, the transfer grain processing fidelity is not high, in order to understand this problem quickly, the market has a film processing, high fidelity, but because the process requirements must be done in the film before powder spraying treatment, coupled with higher requirement on the film itself (the country is more before foreign or joint ventures), so the production cost is higher, in a second tier city high-grade residential.

Send your message to us

Custom Extruded Aluminum Profiles 6061 Alu Profile Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords