Top Quality Small Aluminum Extrusion Profile Sliding Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminum Profile Sliding Windows Top Quality Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminum Profile Sliding Windows Top Quality:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

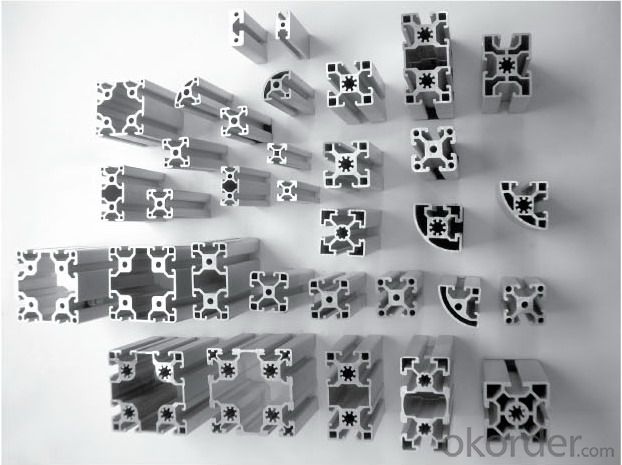

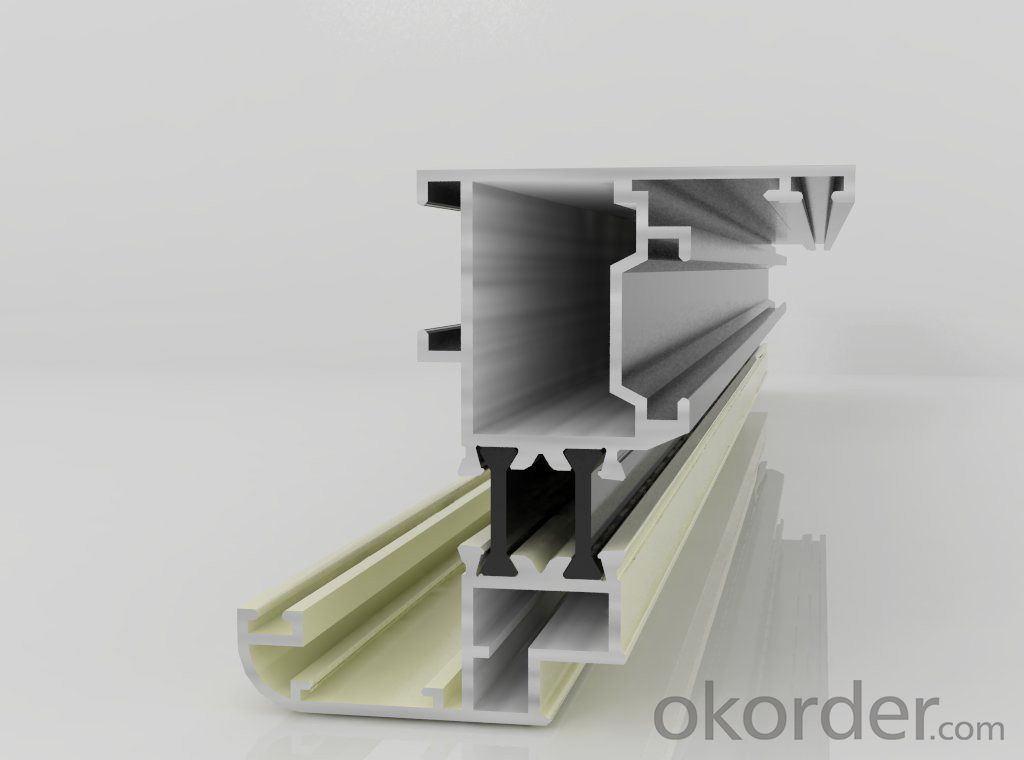

Images of the Aluminum Profile Sliding Windows Top Quality:

Aluminum Profile Sliding Windows Top Quality Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Can aluminum profiles be used in transportation and logistics applications?

- Yes, aluminum profiles can be used in transportation and logistics applications. Aluminum is a lightweight and durable material that is commonly used in the manufacturing of transportation vehicles such as cars, trucks, trains, and airplanes. It is also used in the construction of storage and shipping containers, racks, and shelving systems in logistics applications.

- Q: we recently entered a batch of aluminum billet, under the rain, billet oxidation, spray finished drawing after the profile off the skin, how to do

- If the spray before the rescue, spraying is not easy, you also do not have to estimate the film slot!

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with other metals?

- To prevent galvanic corrosion when combining aluminum profiles with other metals, several measures can be taken. One effective method is to use a barrier between the aluminum and the other metal, such as a coating or a non-conductive material. This barrier helps to isolate the two metals and prevents direct contact, reducing the risk of galvanic corrosion. Additionally, selecting metals with similar electrochemical properties can minimize the potential for galvanic corrosion. Proper insulation and regular maintenance, including ensuring the absence of any electrolytes or moisture, can also help prevent galvanic corrosion in these combinations.

- Q: Can aluminum profiles be recycled indefinitely?

- No, aluminum profiles cannot be recycled indefinitely. While aluminum is highly recyclable and can be recycled multiple times, the quality of the material gradually degrades with each recycling process. Eventually, the aluminum profiles will become unsuitable for further recycling and need to be disposed of.

- Q: Can aluminum profiles be used in cleanroom environments?

- Yes, aluminum profiles can be used in cleanroom environments. Aluminum is a lightweight and versatile material that possesses many desirable qualities for cleanroom applications. It is non-corrosive, non-magnetic, and has a high strength-to-weight ratio, making it suitable for constructing cleanroom structures such as walls, partitions, and equipment racks. Aluminum profiles can be easily assembled and disassembled, allowing for flexible cleanroom configurations and future modifications. They can also be integrated with other materials like glass, acrylic, or stainless steel to meet specific cleanroom requirements. Additionally, aluminum profiles can be anodized or coated to enhance their cleanliness and resistance to contamination. Anodization provides a protective layer on the surface of the aluminum, making it more resistant to scratches and wear. Coatings such as epoxy or powder coatings can further improve the durability and cleanliness of the profiles. Overall, aluminum profiles offer numerous advantages for cleanroom applications, including their lightweight nature, strength, corrosion resistance, and flexibility in design.

- Q: This question asks for the method to determine the amount of aluminum required for a construction project.

- <p>To calculate the weight of aluminum profiles needed for a building project, follow these steps: 1. Determine the length and cross-sectional area of each aluminum profile required. 2. Use the aluminum density, which is approximately 2.7 grams per cubic centimeter (g/cm鲁). 3. Multiply the volume (length 脳 cross-sectional area) by the density to get the weight of each profile. 4. Sum the weights of all profiles to get the total weight needed. Ensure to account for any additional material for joints, connections, and potential waste. It's also advisable to consult with an engineer or use specialized software for precise calculations tailored to your project's specific requirements.</p>

- Q: What are the color options available for aluminum profiles?

- There is a wide range of color choices for aluminum profiles, allowing for customization to meet individual preferences and design requirements. Common color options include silver, white, black, bronze, and different shades of grey. Moreover, it is possible to create custom colors by using powder coating or anodizing techniques on the aluminum profiles. These methods offer a vast array of colors, including vibrant tones and metallic finishes. Ultimately, there are numerous color possibilities for aluminum profiles, ensuring that individuals can find the ideal match for their particular project or aesthetic needs.

- Q: What are the different shapes available in aluminum profiles?

- Aluminum profiles come in a variety of shapes, each serving specific purposes and meeting different structural requirements. Some commonly used shapes include: 1. T-shape: With a horizontal and vertical section, this profile is ideal for creating joints, connections, or support structures. 2. U-shape: Featuring two parallel sides and an open bottom, this profile is commonly used for framing, edging, or as a protective barrier. 3. L-shape: With one longer side and one shorter side, this profile is frequently used for corner brackets, supports, or right-angle connections. 4. Square shape: With equal sides, square profiles are versatile and can be used for a wide range of applications, such as framing, rails, or supports. 5. Round shape: With a circular cross-section, this profile is perfect for applications that require rounded edges or a seamless look, often used for handrails, decorative purposes, or in the automotive industry. 6. Rectangular shape: With two longer sides and two shorter sides, rectangular profiles are often utilized for structural framing, supports, or as beams. 7. I-beam shape: Also known as an H-beam, this profile has a central vertical web and two horizontal flanges, offering excellent strength and commonly used in construction, bridges, or industrial applications. 8. Channel shape: With a U-shaped cross-section and one side shorter than the other, this profile is widely used for structural support, framing, or as tracks for sliding doors and windows. These examples showcase the variety of shapes available in aluminum profiles. The choice of shape depends on specific project requirements, such as load-bearing capacity, design aesthetics, or functionality.

- Q: This question asks for the typical specifications and measurements of aluminum profiles that are used in the construction of building frames.

- <p>Aluminum profiles used in building frames come in various specifications and measurements. Commonly, they include I-beams, T-profiles, and C-channels with different thicknesses and dimensions. Sizes can range from 30mm to 200mm in width and from 1mm to 10mm in thickness. The length of these profiles can vary, but they are often available in standard lengths such as 6 meters. Specific dimensions and tolerances are determined by the building's design requirements, load-bearing needs, and manufacturing standards. It's also important to consider the alloy type, which can affect strength and corrosion resistance. Always consult with an engineer or supplier for the exact specifications suitable for a particular project.</p>

- Q: How do you clean and maintain aluminum profiles?

- To clean and maintain aluminum profiles, you can follow these simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum profiles using a soft brush or cloth. 2. Prepare a cleaning solution by mixing mild dish soap or a non-abrasive cleaner with warm water. Avoid using harsh chemicals or abrasive cleaners as they can damage the aluminum finish. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum profiles. Be sure to clean all the corners and crevices thoroughly. 4. Rinse the profiles with clean water to remove any soap residue. You can use a hose or a bucket of water for this step. 5. Dry the aluminum profiles completely using a soft, lint-free cloth. This will prevent water spots or streaks from forming. 6. For regular maintenance, you can use a specialized aluminum cleaner or polish to restore the shine and protect the surface. Follow the instructions on the product for best results. 7. It is important to avoid using abrasive scrubbers, steel wool, or harsh chemicals as they can scratch or damage the aluminum finish. Also, never use acidic cleaners or vinegar on aluminum as they can cause corrosion. 8. If you notice any scratches or minor damages on the aluminum profiles, you can use a touch-up paint specifically designed for aluminum to repair them. Follow the manufacturer's instructions for application. Remember, regular cleaning and maintenance will help preserve the appearance and longevity of your aluminum profiles.

Send your message to us

Top Quality Small Aluminum Extrusion Profile Sliding Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords