Aluminum Led Extrusion Profiles - Sandblasted Anodized Aluminium Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

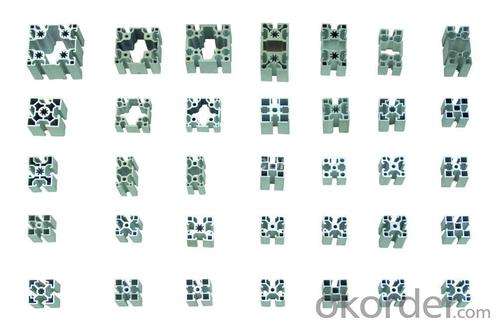

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the different surface protection options available for aluminum profiles?

- Various surface protection options are available for aluminum profiles, depending on specific requirements and applications. 1. Anodizing is a commonly used surface treatment for aluminum profiles. It involves an electrochemical process that creates a protective oxide layer on the surface. Anodizing offers excellent corrosion resistance, durability, and can enhance the profiles' aesthetic appearance with a variety of colors. 2. Another popular option is powder coating. This process applies a dry powder to the profiles' surface through electrostatics, which is then cured under heat to form a protective coating. Powder coating provides durability, scratch resistance, and comes in various colors and finishes. 3. Painting is a traditional method for protecting aluminum profiles. It involves applying a liquid paint coating that safeguards against corrosion, UV radiation, and enhances appearance. Painting offers a wide range of colors and finishes to meet aesthetic requirements. 4. Clear coating is commonly used when preserving the natural appearance of the aluminum profiles is desired. This coating forms a transparent film on the surface, protecting against oxidation, scratches, and other environmental factors while showcasing the metallic look. 5. Film coating, also known as protective film or peelable coating, is a temporary option. A thin layer of film is applied to protect the profiles during transportation, handling, or installation. The film can be easily peeled off after installation, leaving a clean surface. 6. Mechanical finishing techniques such as brushing, polishing, or sandblasting can improve the surface appearance of aluminum profiles. These methods can achieve desired texture, gloss level, or remove imperfections. While they do not provide long-term protection, they can be combined with other options for enhanced aesthetics. Overall, choosing the appropriate surface protection option for aluminum profiles depends on factors like intended application, desired aesthetics, durability requirements, and cost considerations. Selecting the most suitable option ensures the profiles' longevity and performance.

- Q: Can aluminum profiles be used in interior design applications?

- Certainly, aluminum profiles are a fantastic option for incorporating into interior design projects. Thanks to its versatility and durability, aluminum offers countless design possibilities. In fact, it can be utilized to fabricate a wide range of features, including doors, windows, partitions, furniture frames, lighting fixtures, and decorative accents within interior spaces. Aluminum profiles come in diverse shapes, sizes, and finishes, allowing for customization and adaptability in design. They can be anodized, powder-coated, or painted to match any desired color scheme. Moreover, aluminum profiles can be effortlessly shaped and manipulated to produce unique and intricate designs. One notable advantage of utilizing aluminum profiles in interior design is their lightweight composition, making them easy to install and handle. Additionally, aluminum is resistant to corrosion, enabling it to withstand moisture and humidity in areas such as bathrooms and kitchens. Furthermore, aluminum profiles offer long-lasting durability, as they resist warping, cracking, and fading. Consequently, they are an ideal choice for high-traffic areas or commercial spaces that require frequent use. Regarding aesthetics, aluminum profiles can provide a contemporary and streamlined appearance, elevating the overall design of a space. They can be paired with other materials like glass or wood to achieve a modern and sophisticated look. Furthermore, aluminum is an environmentally friendly and sustainable material. It can be fully recycled, thereby contributing to a reduced carbon footprint and a more sustainable approach to design. In conclusion, aluminum profiles are an excellent option for various interior design applications. Their versatility, durability, lightweight composition, and aesthetic appeal make them a popular choice for designers seeking functional and visually appealing solutions for interior spaces.

- Q: What are the different types of surface protection for aluminum profiles?

- There are several different types of surface protection options available for aluminum profiles. These options are designed to enhance the durability and aesthetics of the aluminum profiles and provide protection against various environmental factors. 1. Anodizing: Anodizing is one of the most common methods of surface protection for aluminum profiles. It involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides excellent corrosion resistance and can be done in various colors. 2. Powder Coating: Powder coating involves applying a dry powder to the surface of the aluminum profiles, which is then cured under heat to form a protective layer. Powder coating offers a wide range of color options, excellent durability, and resistance to scratching, chipping, and fading. 3. Paint: Painting is another option for surface protection of aluminum profiles. It involves applying a liquid paint coating to the surface, which provides both protection and aesthetic enhancement. Paint can be customized in terms of color, texture, and finish, but it may not be as durable as other options. 4. Clear Coating: Clear coating is a transparent protective layer that can be applied to aluminum profiles. It provides a glossy finish while preserving the natural appearance of the aluminum. Clear coating offers protection against corrosion, UV radiation, and other environmental factors. 5. Cladding: Cladding involves covering the aluminum profiles with another material, such as stainless steel or composite panels. This provides additional protection against corrosion and wear, while also adding aesthetic appeal and design versatility. 6. Film/Protective Tape: Applying a temporary film or protective tape to the surface of aluminum profiles can provide short-term protection during transportation, installation, or construction. These films or tapes can be easily removed after use, leaving the aluminum profile intact. Each of these surface protection options has its own advantages and disadvantages, and the choice depends on the specific requirements of the application, desired aesthetics, budget, and expected environmental conditions.

- Q: How do aluminum profiles handle extreme weather conditions?

- Aluminum profiles are known for their excellent resistance to extreme weather conditions. Due to their inherent corrosion resistance, they can withstand exposure to rain, snow, UV radiation, and high temperatures without deteriorating or losing their structural integrity. Additionally, aluminum profiles have a low thermal expansion coefficient, making them highly stable and resistant to warping or cracking in extreme temperature fluctuations. Overall, aluminum profiles are a reliable choice for outdoor applications, as they can handle a wide range of weather conditions with minimal maintenance.

- Q: Are aluminum profiles suitable for exhibition stands?

- Yes, aluminum profiles are suitable for exhibition stands. Aluminum is a popular choice for exhibition stands due to its lightweight nature, durability, and versatility. Aluminum profiles can be easily assembled and disassembled, making them convenient for transportation and installation at different exhibition venues. Additionally, aluminum profiles can be customized to create various shapes and sizes, allowing for unique and eye-catching exhibition stand designs. The material also offers a sleek and professional appearance, making it suitable for showcasing products or services at trade shows or exhibitions. Furthermore, aluminum profiles can be easily modified or extended if changes need to be made to the exhibition stand layout. Overall, aluminum profiles are an excellent choice for exhibition stands due to their practicality, aesthetic appeal, and adaptability.

- Q: Can aluminum profiles be used in elevator or escalator systems?

- Yes, aluminum profiles can be used in elevator or escalator systems. Aluminum profiles are lightweight, durable, and corrosion-resistant, making them suitable for various applications, including the construction of elevator and escalator components. Aluminum profiles can be used for the structural framework, handrails, cladding, and other parts of an elevator or escalator system. Additionally, aluminum profiles can be easily customized and fabricated to meet the specific requirements of each project. Their versatility, strength-to-weight ratio, and aesthetic appeal make aluminum profiles an excellent choice for elevator and escalator systems.

- Q: Are aluminum profiles suitable for cleanroom applications?

- Indeed, cleanroom applications can benefit from the use of aluminum profiles. Due to its lightweight and durable nature, aluminum proves to be an ideal material that resists corrosion, which is crucial in environments where cleanliness and hygiene are of utmost importance. The ease of cleaning and sterilizing aluminum profiles, along with their smooth surface that prevents the accumulation of dirt, dust, or particles, ensures the preservation of a contamination-free atmosphere within cleanrooms. Moreover, aluminum profiles can be tailored to fit specific requirements and effortlessly integrated with other cleanroom elements, such as panels and doors, resulting in a seamless and hygienic environment. Ultimately, aluminum profiles possess the necessary strength, cleanliness, and adaptability essential for cleanroom applications.

- Q: This question is asking about the various types of insulation materials that can be used with aluminum profiles, which are commonly found in construction and manufacturing for their strength and light weight.

- <p>There are several types of insulation available for aluminum profiles, including thermal insulation, acoustic insulation, and electrical insulation. Thermal insulation materials such as polyurethane foam or mineral wool can be used to prevent heat transfer. Acoustic insulation, like soundproofing panels or rubber seals, can reduce noise transmission. Electrical insulation is crucial for preventing electrical conductivity and can be achieved with materials like neoprene or silicone rubber. Each type serves a specific purpose and is chosen based on the application's requirements, such as temperature control, noise reduction, or electrical safety.</p>

- Q: Are aluminum profiles suitable for signage and advertising displays?

- Yes, aluminum profiles are highly suitable for signage and advertising displays. Aluminum is a lightweight and durable material that is resistant to corrosion, making it ideal for outdoor applications. It can withstand various weather conditions without losing its structural integrity, ensuring longevity and reliability for signage and advertising displays. Additionally, aluminum profiles offer versatility in design and customization. They can be easily shaped and molded into different forms and sizes, allowing for the creation of eye-catching and unique displays. Aluminum profiles also provide a sleek and modern appearance, adding a professional touch to any signage or advertising display. Furthermore, aluminum profiles are highly compatible with other materials commonly used in signage and advertising, such as acrylic, PVC, and LED lighting. This compatibility allows for the integration of different elements, such as illumination, to enhance the visibility and impact of the displays. Moreover, aluminum profiles offer easy installation and maintenance. They can be easily assembled, disassembled, and reconfigured as needed. Their lightweight nature makes them easy to handle, reducing installation time and costs. Additionally, aluminum profiles require minimal maintenance, as they do not rust or deteriorate easily. In conclusion, aluminum profiles are an excellent choice for signage and advertising displays. They offer durability, versatility, compatibility, and ease of installation and maintenance. Whether for outdoor or indoor applications, aluminum profiles can provide a visually appealing and long-lasting solution for effective signage and advertising.

- Q: This question asks for a method to determine the quantity of aluminum profiles needed for a construction project.

- <p>To calculate the amount of aluminum profiles required for a building project, follow these steps: 1. Determine the project's design and specifications to identify where aluminum profiles are needed. 2. Measure the dimensions of the areas requiring aluminum profiles (length, width, height). 3. Calculate the total linear footage needed by multiplying the dimensions. 4. Consider the profile's cross-sectional area and the project's load-bearing requirements. 5. Account for waste and additional material for joints, connections, and potential errors. 6. Consult with suppliers or use industry-standard formulas to determine the exact quantity of profiles needed. 7. Review and adjust calculations as the project progresses to ensure accuracy.</p>

Send your message to us

Aluminum Led Extrusion Profiles - Sandblasted Anodized Aluminium Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords