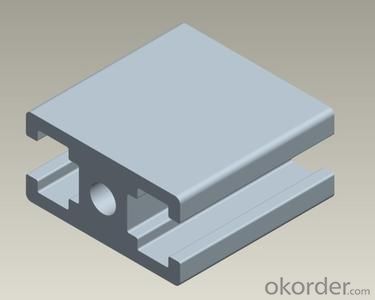

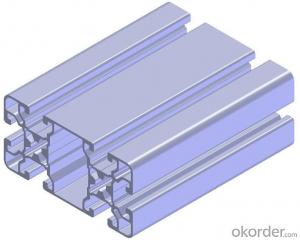

Sandblasting Anodizing Aluminum Alloy Profile Accessories

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: Can aluminum profiles be used in the production of agricultural equipment?

- Aluminum profiles have the potential to be utilized in the manufacturing of agricultural equipment. The versatility and lightweight characteristics of aluminum provide numerous benefits for agricultural applications. Its resistance to corrosion is crucial when considering equipment that is exposed to outdoor conditions and various farming chemicals. Moreover, aluminum profiles have the capability to be easily molded and customized to meet specific design requirements, enabling the creation of intricate and functional agricultural equipment. The lightweight nature of aluminum also simplifies the transportation and handling of the equipment, resulting in reduced labor costs. Additionally, aluminum profiles are recyclable, making them an environmentally conscious choice for the production of agricultural equipment. In conclusion, incorporating aluminum profiles into agricultural equipment can enhance durability, efficiency, and sustainability within the farming industry.

- Q: What are the different fastening options available for aluminum profiles?

- Some of the different fastening options available for aluminum profiles include screws, bolts, nuts, rivets, and adhesive bonding.

- Q: Are there any materials for aluminum profiles?

- According to alloy compositionCan be divided into 1024, 2011, 6063, 6061, 6082 and 7075 grade aluminum alloy, which is the 6 most common. Grades are different in various metal components ratio is not the same, except for the commonly used aluminum profile doors and windows such as the 60 series, 70 series, 80 series, 90 series, curtain wall series aluminum profile, aluminum industry has no clear distinction model, most manufacturers are in accordance with the actual drawings of customers.By surface treatment1. anodized aluminum2. electrophoresis coating aluminum material3. powder spraying aluminum material4. wood grain transfer aluminum5. fluorocarbon spraying aluminium material6., polishing aluminum (divided into mechanical polishing and chemical polishing two kinds, in which the highest cost of chemical polishing, the price is also the most expensive)

- Q: Are aluminum profiles suitable for structural applications?

- Indeed, aluminum profiles prove to be fitting for structural applications. Boasting a lightweight composition, aluminum exhibits remarkable versatility, coupled with an exceptional strength-to-weight ratio, corrosion resistance, and durability. Consequently, it becomes an ideal choice for an array of structural purposes, encompassing architectural frameworks, bridges, aerospace structures, automotive frames, and industrial equipment. Moreover, the malleability of aluminum profiles permits effortless fabrication, welding, and joining, facilitating efficient construction and customization. By incorporating appropriate design and engineering considerations, aluminum profiles can ensure the essential strength and stability demanded by structural applications.

- Q: Can aluminum profiles be used for escalator steps?

- Yes, aluminum profiles can be used for escalator steps. Aluminum is a lightweight and durable material that can withstand the weight and constant movement associated with escalator steps. Additionally, aluminum profiles can be easily customized and shaped to fit the specific design requirements of escalators.

- Q: Can aluminum profiles be used for solar panel installations?

- Solar panel installations can make use of aluminum profiles, which are frequently employed in the construction industry because of their lightweight nature, durability, and resistance to corrosion. These attributes make aluminum an optimal material for supporting and securing solar panels. Aluminum profiles can be easily customized and fabricated to meet specific installation requirements, including roof or ground mounting systems. Furthermore, aluminum possesses exceptional thermal conductivity, enabling efficient dissipation of heat from the solar panels. This characteristic is vital for maintaining their performance and lifespan. In addition, aluminum profiles are commonly utilized to frame solar panels, providing structural support and ensuring stability in diverse weather conditions. All in all, aluminum profiles are a favored option for solar panel installations due to their robustness, longevity, and adaptability.

- Q: Can aluminum profiles be used in automotive applications?

- Yes, aluminum profiles can be used in automotive applications. Aluminum profiles are lightweight, strong, and corrosion-resistant, making them suitable for various automotive components such as body panels, chassis parts, and engine components. Their use helps reduce the overall weight of the vehicle, improving fuel efficiency and performance.

- Q: Are aluminum profiles suitable for use as exterior wall materials?

- <p>Yes, aluminum profiles can be used for exterior walls. They are known for their durability, resistance to weathering, and low maintenance requirements. Aluminum is lightweight, strong, and can be easily shaped into various designs. It also has excellent resistance to corrosion, making it ideal for outdoor applications. Additionally, aluminum profiles can be powder coated or anodized for enhanced protection and aesthetic appeal, allowing them to blend well with different architectural styles.</p>

- Q: Can aluminum profiles be used in exhibition or trade show displays?

- Exhibition or trade show displays can incorporate aluminum profiles, which are lightweight, durable, and versatile. These profiles are an excellent option for constructing exhibition displays due to their ability to be easily assembled and disassembled, enabling swift setup and dismantling at trade shows. Furthermore, aluminum profiles can be tailored to produce diverse shapes and sizes to accommodate various exhibition booth designs. They can also be effortlessly combined with other materials like fabric, glass, or acrylic panels to create visually appealing and professional displays. Ultimately, aluminum profiles present a practical and cost-effective solution for exhibition or trade show displays.

- Q: and I know the meaning of 125MN is 12500 tons. I want to know if 125MN is a English an abbreviation of the word, if it is, then what is he, if he is not that what is the meaning?

- MN is an international unit, said the bull"125MN's extruder is 12500T's extruderBloomberg metal Forum

Send your message to us

Sandblasting Anodizing Aluminum Alloy Profile Accessories

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords