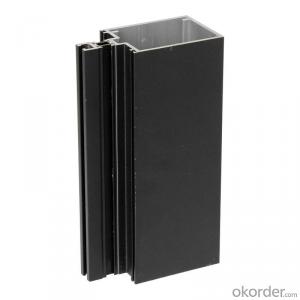

Custom China Extruded Aluminum Profiles - Best Selling Colorful Anodizing Aluminium Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium profile

1) Alloy: AA6061, AA6063

2) Temper: T5, T6

3) Series of surface treament:

1. Mill Finished

2. Anodizing: Silver, champagne, light bronze, dark bronze, black, light titanium, dark titanium.

3. Electrophoretic Coating: Silver, champagne, bronze, black, light bronze, dark bronze.

4. Electrostatic Color Powder Coating: Normal color, special color.

5. Fluorocarbon Powder Spraying: Normal color, special color.

6. Wood Grain Coating: Import paper, domestic paper.

- Q: What are the different surface treatments for aluminum profiles?

- Some of the different surface treatments for aluminum profiles include anodizing, powder coating, painting, and polishing.

- Q: This question asks for various methods of producing aluminum profiles in a manner that is both efficient and cost-effective.

- <p>Efficient and cost-effective manufacturing of aluminum profiles can be achieved through several methods: 1) Using advanced extrusion technology, which is the primary method for shaping aluminum profiles, allows for high production rates and consistent quality. 2) Implementing automation in the production process to reduce labor costs and increase output. 3) Employing recycling techniques to use scrap aluminum, which lowers material costs and is environmentally friendly. 4) Optimizing the design of profiles to reduce material usage without compromising strength. 5) Utilizing energy-efficient equipment and processes to minimize energy consumption. 6) Regular maintenance and upgrading of machinery to ensure operational efficiency and reduce downtime. 7) Implementing just-in-time inventory management to minimize storage costs and reduce waste. 8) Continuous improvement through research and development to find new, more efficient methods of production.</p>

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: This question asks about the various types of surface treatments or finishes that can be applied to aluminum profiles.

- <p>Aluminum profiles can be coated with different types of finishes to enhance their appearance, durability, and resistance to corrosion. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a durable and colorful finish applied through an electrostatic process. 3. Electrophoretic coating, a method that uses electric current to apply a paint-like coating. 4. PVDF coating, a high-performance finish with excellent weather resistance. 5. Thermal spraying, which applies a coating through a high-velocity flame. 6. Vacuum coating, a process that deposits thin layers of material in a vacuum chamber. Each type of coating has specific properties and applications, making them suitable for different environments and uses.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are utilized in the construction of interior partitions and ceilings.

- <p>Aluminum profiles for interior partitions and ceilings come in various types, each serving specific purposes and functions. Common types include: 1. U-Channel profiles, used for creating the framework of ceilings and partitions. 2. T-profiles, often used as a cover for the joints between panels. 3. H-profiles, which are used as main beams in ceiling systems. 4. Angle profiles, used for corner connections and support. 5. Flat bar profiles, used for decorative or functional purposes in ceilings and partitions. 6. Box profiles, which can be used for both structural and aesthetic applications. 7. Special profiles, designed for specific applications such as lighting fixtures or air conditioning ducts. These profiles are chosen based on the design requirements, load-bearing needs, and aesthetic preferences for the project.</p>

- Q: How do you calculate the weight-bearing capacity of aluminum profiles?

- When determining the weight-bearing capacity of aluminum profiles, several factors must be taken into account. These include the profile dimensions, the grade of aluminum used, and the specific requirements of the application. To start, it is necessary to ascertain the dimensions of the aluminum profile, including its length, width, and thickness. These measurements are crucial for calculating the cross-sectional area, a key parameter in determining the profile's load-bearing capacity. Next, the material grade of the aluminum used must be considered. Different aluminum alloys possess varying strength properties, so it is essential to know the specific alloy and temper designation. This information can be obtained from the manufacturer or supplier. Once the cross-sectional area and material grade are known, engineering standards or handbooks can be consulted. These resources provide load tables or formulas for calculating the safe load capacity of aluminum profiles. They offer a range of load ratings based on different loading conditions, such as static or dynamic loads, as well as factors like span length, support conditions, and safety factors. It is also crucial to take into account any additional factors that might affect the load-bearing capacity. These could include temperature, vibration, or potential impact forces. Adjustments to the calculated load capacity might be necessary to accommodate these factors. Furthermore, seeking advice from a structural engineer or an aluminum profile manufacturer can be highly beneficial. They can provide valuable insights and recommendations for more accurate calculations. They may possess specialized knowledge or testing data specific to the aluminum profile being considered, ensuring a more reliable assessment. In conclusion, calculating the weight-bearing capacity of aluminum profiles involves considering the dimensions, material grade, and specific application requirements. Consulting relevant resources or experts in the field is necessary to ensure accurate and safe load calculations.

- Q: Can aluminum profiles be used in the construction of retail displays?

- Yes, aluminum profiles can be used in the construction of retail displays. Aluminum is a versatile and lightweight material that is commonly used in various industries, including construction and retail. It offers several advantages for retail displays, such as durability, corrosion resistance, and ease of customization. Aluminum profiles can be easily shaped and fabricated to create different types of retail displays, such as shelving units, display stands, signage frames, and product showcases. These profiles can be extruded into different shapes and sizes, allowing for flexibility in design and functionality. Additionally, aluminum profiles can be finished with various surface treatments, such as anodizing or powder coating, to enhance their appearance and provide a protective layer against scratches and wear. This allows retail displays to maintain their aesthetic appeal and withstand the demands of a retail environment. Furthermore, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for retail displays. It can be easily recycled without losing its properties, reducing the environmental impact of construction and retail industries. In summary, aluminum profiles are a suitable and practical choice for the construction of retail displays. They offer durability, versatility, and customization options while being lightweight and environmentally friendly.

- Q: Are aluminum profiles suitable for cleanroom partitions?

- Yes, aluminum profiles are often suitable for cleanroom partitions. Aluminum is a lightweight and durable material that is resistant to corrosion, making it a popular choice for cleanroom applications. It is easy to clean and maintain, which is crucial in maintaining the cleanliness and sterility of a cleanroom environment. Additionally, aluminum profiles can be easily customized and assembled, allowing for flexibility in designing cleanroom partitions to meet specific requirements. The versatility of aluminum profiles also enables the integration of various features such as doors, windows, and pass-through chambers, further enhancing the functionality of cleanroom partitions. Overall, with their excellent properties and adaptability, aluminum profiles are a reliable and suitable choice for cleanroom partitions.

- Q: What are the specific features of industrial aluminum profiles?

- Abrasion resistance, corrosion resistance, anti oil Department of Chongqing Lixing

- Q: This question asks about the various methods employed in the production of aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, which involves forcing aluminum through a die to create specific shapes. Other processes include casting, where aluminum is poured into molds, and rolling, used to create flat sheets or plates. Machining processes like cutting, drilling, and milling are also used for further shaping and finishing. Additionally, aluminum profiles can be fabricated through bending, which shapes the material into curves or angles, and welding, which joins pieces together. Surface treatments like anodizing, painting, or powder coating are also applied to enhance appearance and durability.</p>

Send your message to us

Custom China Extruded Aluminum Profiles - Best Selling Colorful Anodizing Aluminium Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords