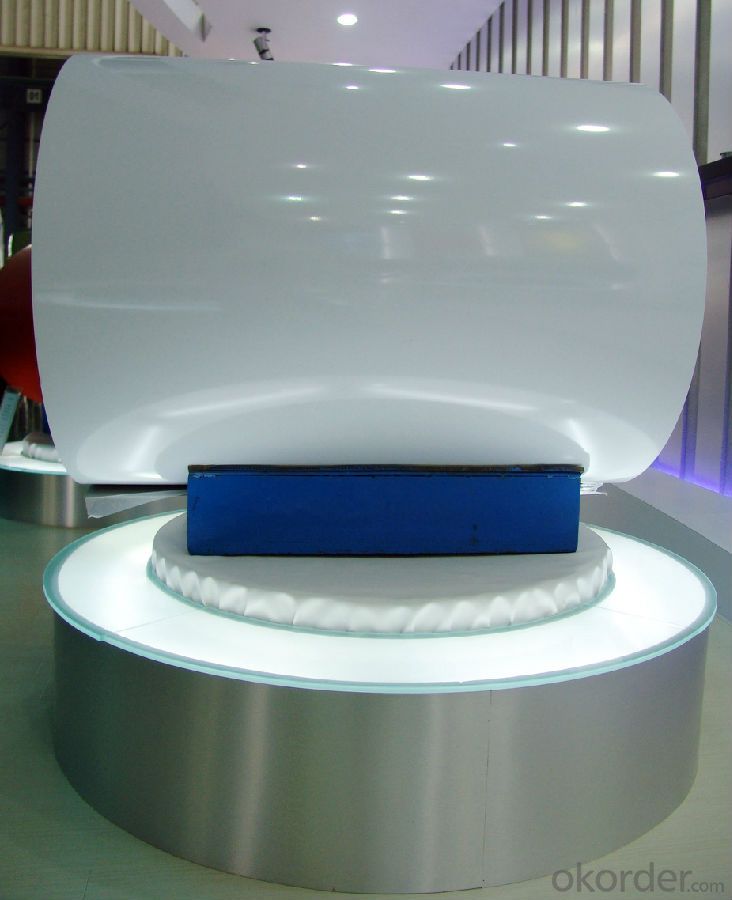

Rolled Steel Coil Quotes for Galvalume Steel Coil/Gl/Zinc Aluminized Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specification:

| Product Name: | Galvalume steel coil/GL/Zinc Aluminized steel |

Standard: | JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB |

| Price: | US $600-800 / Metric Ton |

| Trade Terms: | FOB/CNF/CIF |

| Supply Ability: | 30000 Metric Ton monthly |

| Packing: | standard exporting packing or at buyer's requirement |

| Payment Terms: | L/C,T/T |

| Delivery time: | Within 15-30days after we receive deposit or L/C at sight |

| Specifications: | Brand Name :CNBM Thickness:0.14-0.6mm Type:coil/sheet/strips Width:600- 1250mm Length: Zinc Coating:40g-150g/ Coil ID :508mm or 601mm Coil Weight :3-8MT Place of Origin:China Tianjing,shanghai Standard: AISI, ASTM, BS, DIN, GB, JIS Technique:Cold Rolled Surface Treatment:Anti-finger |

Application

1. Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

2. Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

3. Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

4. Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Service

1.MOQ:25 ton.

2.Delivery time;15-30days

3.Payment:30% deposite, 70% in L/C before delivery or T/T

4.We can guarantee 100% inspeciton before the shipment

5.We can 100% supply MTC.

Q&A What is your acceptable payment term?

ANSWER: TT,LC,OA etc

- Q:How are steel coils used in the production of metal facades?

- The production of metal facades relies on steel coils as a vital element. These coils, typically crafted from high-quality steel, serve as the raw material for manufacturing different components of metal facades, including panels, cladding, and roofing sheets. During the production process, the steel coils go through a series of procedures. Initially, the coils are uncoiled and flattened to achieve a smooth and uniformly thick surface, ensuring the desired texture for the metal facades. Subsequently, the flattened coils are cut into specific lengths and widths, tailored to meet the design requirements of the facades. After the cutting process, the steel sheets undergo various surface treatment techniques, such as cleaning, pickling, and coating. These treatments are crucial in enhancing the durability and corrosion resistance of the metal facades. The coatings are applied using different methods, such as galvanization, powder coating, or painting, depending on the desired finish and level of protection needed. Once the surface treatment is completed, the steel sheets are shaped and formed into the desired profiles for the metal facades. This can involve processes like roll forming, bending, or stamping, depending on the complexity of the design. These shaping processes give the metal facades their distinct appearance and structural integrity. Finally, the formed steel sheets are assembled and installed onto the building structure to create the metal facade. The installation techniques employed include welding, riveting, or adhesive bonding, depending on the specific project requirements. Thus, the steel coils play a critical role in providing the necessary raw material for the production of metal facades. These facades not only enhance the aesthetic appeal of buildings but also provide protection and durability against harsh weather conditions. To summarize, steel coils are indispensable in the production of metal facades as they serve as the raw material for various components. They undergo surface treatments to enhance durability, are shaped into desired profiles, and finally, installed to create the metal facade.

- Q:How are steel coils used in the production of scaffolding?

- Steel coils are used in the production of scaffolding as they are typically cut and shaped into various components such as tubes, frames, and brackets. These coils provide the necessary strength and durability required for scaffolding structures, ensuring the safety and stability of workers who use them.

- Q:I'm trying to buy a Survival,tactical knife but don't know what steel is better

- Vanadium Steel Knives

- Q:Which of the two are better for exhaust manifolds, im guessing the stainless steel right?

- Cast iron. That's what OEMs use obviously it's better. Bring on the Thumbs Down from the peanut gallery.

- Q:What are the common methods of forming steel coils?

- The common methods of forming steel coils include hot rolling, cold rolling, and strip casting.

- Q:So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- Say The radius of steel ball is R. Its shell is t thick so the air filled cavity if of radius r where r = R - t Steel has a density p The mass of the ball m is given m = 4/3 pi (R^3 - r^3) p If the ball is just to float then the mass dived by the must equal the density fo water d d = m / 43/ pi R^3 Equating m in the above equations yields (r/R)^3 = (p - d)/p or r = c R where c =((p-d)/p))^1/3 Using above leads to m = 4/3 pi R^3 (1 - c^3) p and hence R can be solved for So taking p (density of steel) 490 lb/ft^3 and d (density of water) at 62 lb/ft^3 yields c= 0.9557 Applying the equation above gives R = 1.565 ft or a diameter of 37.55 in The shell thickness is R (1 - c) or 0.06938 ft or 0.8327 in Note I do all my work in metric units so I had to do some conversions on the run. I hope you will check things to make sure the maths is correct. Anyway good luck

- Q:i have a question on a test and the questions before it are about blast furnace, wrought iron and cast iron...question 16 is..What is Steel?i dont really get what im being asked.. there could be many answers, what answer are they looking for?

- as steel is an alloy i thinkl they are looking for what elements it is made up of

- Q:How do steel coil manufacturers ensure timely delivery?

- Steel coil manufacturers ensure timely delivery through various strategies and measures. First and foremost, they maintain a well-coordinated production and supply chain management system. This includes efficient scheduling of production processes, monitoring of inventory levels, and close coordination with suppliers of raw materials. Additionally, steel coil manufacturers often employ advanced forecasting techniques to predict the demand for their products. By analyzing historical data, market trends, and customer behavior, they can anticipate future orders and plan their production accordingly. This proactive approach minimizes the risk of delays and allows for better resource allocation. Furthermore, manufacturers work closely with transportation and logistics companies to ensure smooth and timely delivery. They establish strategic partnerships and negotiate favorable agreements to facilitate efficient transportation of steel coils to customers. This includes optimizing routes, utilizing reliable carriers, and closely tracking shipments to promptly address any unforeseen issues. Moreover, manufacturers may maintain buffer stocks to mitigate the impact of unexpected disruptions, such as equipment failures or supplier delays. By having a safety stock of finished products, they can quickly respond to urgent orders and maintain their delivery commitments. Lastly, effective communication plays a crucial role in ensuring timely delivery. Steel coil manufacturers maintain open lines of communication with their customers, keeping them informed about production progress and potential delays. This transparency allows for proactive problem-solving and helps in managing customer expectations. In conclusion, steel coil manufacturers ensure timely delivery by maintaining efficient production and supply chain management systems, utilizing advanced forecasting techniques, collaborating with transportation and logistics companies, maintaining buffer stocks, and maintaining effective communication with customers. These strategies collectively enable them to meet delivery deadlines and provide reliable service to their customers.

- Q:Is cold steel actually steel? Does it hurt? Why is it used in training? First one to goodly answer those questions gets 10 points.

- Cold steel was an expression originally used to signify a sword. From feeling the cold of the blade as it entered the body.

- Q:How do steel coils affect the quality of finished products?

- The quality of finished products in various industries can be greatly influenced by steel coils. Dimensional accuracy and consistency are key factors that determine the impact of steel coils on product quality. When steel coils are not properly manufactured or have irregular dimensions, it can cause issues in the production process and result in finished products that do not meet the desired specifications. Moreover, the final appearance and performance of finished products are heavily dependent on the surface quality of steel coils. Defects such as scratches, rust, or unevenness in the coils can have a negative impact on the aesthetic appeal of the products, making them less desirable to customers. Additionally, these defects can compromise the functionality and durability of the finished products, potentially leading to failures or a reduced lifespan. The mechanical properties of steel coils also play a crucial role in determining the quality of finished products. Coils with inconsistent or inadequate mechanical properties can compromise the strength, toughness, and overall performance of the end products. This is especially important in industries like automotive or construction, where strength and reliability are of utmost importance. The use of steel coils with incorrect mechanical properties can lead to safety hazards or structural failures. Furthermore, the chemical composition of steel coils can have a significant impact on the quality of finished products. The presence of impurities or variations in the alloying elements can affect the material's corrosion resistance, weldability, and other important properties. This, in turn, can affect the longevity and functionality of the final products. In conclusion, steel coils have a significant influence on the quality of finished products. Their dimensional accuracy, surface quality, mechanical properties, and chemical composition all contribute to the overall performance, appearance, and durability of the end products. Therefore, it is essential to ensure that steel coils used in manufacturing processes meet the required standards to achieve high-quality finished products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rolled Steel Coil Quotes for Galvalume Steel Coil/Gl/Zinc Aluminized Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords