PPAL Color Coated Aluminum Coil PPGI PPGL GI GL PPGIPPGL

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Color Coated Aluminum Coil PPAL

Product | PPAL |

Capacity | 10,000 tons/month |

Base material | Aluminum Coil |

Thickness | 0.10-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | |

Color | RAL No. or customers samples’ color |

Zinc-coating | |

Coil ID | 508mm/610mm |

Technique | Aluminum coil—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Color Coated Aluminum Coil PPAL

APPLICATION OF OUR PREPAINTED STEEL | ||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit |

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |

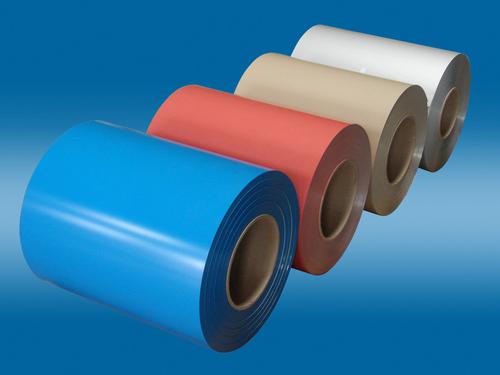

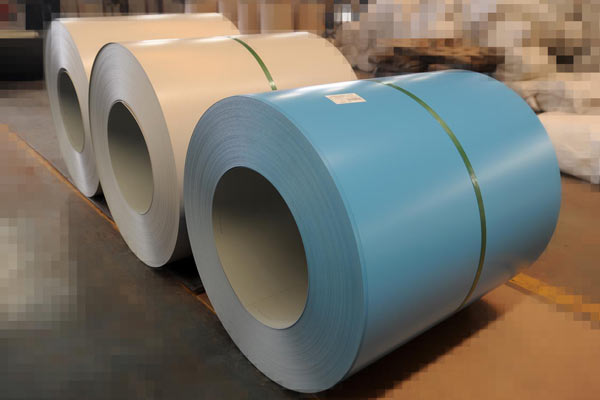

Products Show of Color Coated Aluminum Coil PPAL

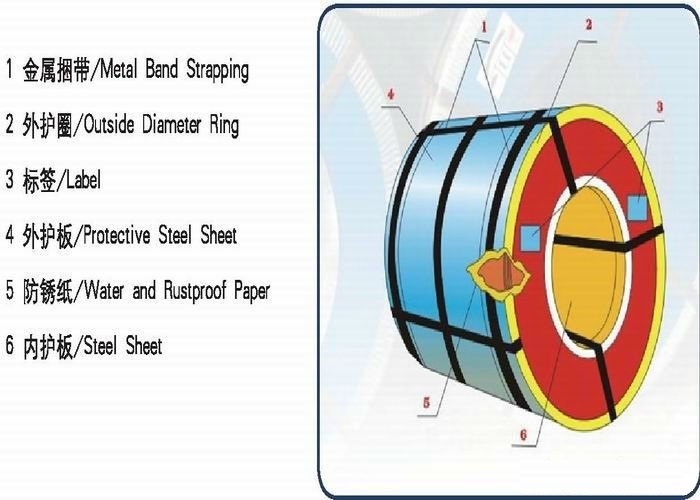

Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. |

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . |

3.Having two series producttion line,with the abbual production capacity of 240000 tons. |

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards |

5.Meet with ROHS standard |

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

We are a trading company but we have so many protocol factories and We works as a trading department of these factories. Also We are the shareholders of the factory.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can steel coils be used in the production of agricultural equipment?

- Yes, steel coils can be used in the production of agricultural equipment. Steel coils are often used as a raw material in the manufacturing of various agricultural equipment such as plows, planters, harvesters, and tillers. The high strength and durability of steel make it suitable for heavy-duty applications in agriculture. Additionally, steel coils can be easily shaped and formed into different parts and components required in agricultural machinery. The corrosion resistance of steel also ensures that the equipment can withstand harsh weather conditions and prolong its lifespan. Overall, the use of steel coils in the production of agricultural equipment helps in ensuring the reliability, longevity, and efficiency of the machinery used in farming operations.

- Q: I need to know where to go online to buy a steel cage for a wrestling ring.. Somebody please assist me?

- the only thing you can find is a bird cage because their is no way you can buy a steel cage unless you build it yourself

- Q: How are steel coils processed and shaped into specific products?

- The production of specific steel products involves a series of steps and techniques using different machinery. Initially, steel coils are unwound and flattened using a decoiler and a leveller. This prepares the coils for further processing. Next, the flattened coils are fed into a rolling mill where they undergo cold rolling. This process involves passing the coils through rollers to reduce thickness, improve surface finish, and enhance strength and hardness. After cold rolling, additional processes like annealing or galvanizing may be applied depending on the desired properties of the final product. Annealing involves heating the coils to a specific temperature and slowly cooling them to relieve internal stresses and improve ductility. Galvanizing, on the other hand, involves coating the coils with a layer of zinc to protect against corrosion. Once these treatments are completed, the steel coils are ready to be shaped into specific products. This can be achieved through cutting, stamping, or forming. Cutting involves trimming the coils into desired sizes or lengths using shears or lasers. Stamping involves using a die and press to shape the coils into intricate designs or patterns. Forming, on the other hand, involves bending or shaping the coils with specialized machinery to create curved or contoured products. Finally, the shaped steel products are inspected for quality and undergo any necessary finishing processes like painting or coating. This ensures that the products meet required specifications and are ready for distribution or further assembly. In conclusion, the transformation of steel coils into specific products involves a combination of steps including unwinding, flattening, cold rolling, annealing or galvanizing, cutting, stamping, forming, inspection, and finishing. Each step is essential in producing high-quality steel products used across various industries.

- Q: What are the different types of steel coil surface appearances?

- The different types of steel coil surface appearances include hot rolled, cold rolled, galvanized, coated, and textured finishes.

- Q: How are steel coils inspected for paint adhesion using adhesion testers?

- Steel coils are inspected for paint adhesion using adhesion testers by applying a controlled amount of force to a specially prepared test area on the coil's surface. The adhesion tester measures the amount of force required to remove the paint coating from the surface, providing a quantitative assessment of the paint adhesion. This process helps ensure the quality and durability of the paint coating on the steel coils.

- Q: Can anyone please tell me what is the DUCTILE TO BRITTLE TRANSITION TEMPERATURE IN STEEL LOW CARBON?Thanks.

- Transition Temperature Of Steel

- Q: what are the characteristics when of iron or steel when stretched? which one could be stretched further? which one stretches more evenly?thankyou

- Steel is harder and more brittle than iron since it has impurities which disrupt the regular layers of atoms. This means that the iron will stretch further and more easily. This also means it will stretch more easily.

- Q: I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- I do not know that gun. I have the over/unders. A little checking. Now checking the specs it does describe the barrel steel, and that it is threaded to standard Rem Choke size threads. So before you shoot steel if you do not know what choke you have go to any gunshop and ask them to just stick their choke gauge in the choke. On the choke itself it should say what choke it is. For steel shot you should use one choke size LARGER then the way you want the gun to pattern. ie. A modified choke will shoot a full choke pattern. An Improved cylinder choke a modified pattern and so on. DO NOT use a full choke. the full choke is too tight, and steel shot does NOT deform like lead does. The first indication of a problem would be a bulge in the barrel out near the muzzle end. Run your hand down and feel it. The barrel steel is fine though just use or get the correct choke tube, AND what I said is if you so not have anything BUT a full choke buy a Rem Choke the size you want. Even Walldog sells Rem Chokes.

- Q: Just two sentences on a detailed description on what the steel industry is

- The steel industry is an industry that produces steel. It is one of the largest industries in the world, with China as the leading steel producer

- Q: Do you know of any movies that featured the steel drum?

- You okorder /.. If I can find any clips, I'll add them, but I'm sure that many movies in the proper settings (Trinidad, etc.) would have such music and/or show a group or at least a single performer. For example, Cool Running could be a possibility.

Send your message to us

PPAL Color Coated Aluminum Coil PPGI PPGL GI GL PPGIPPGL

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords