Hot Sell Aluzinc Steel Coil-JIS G3321

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- -

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

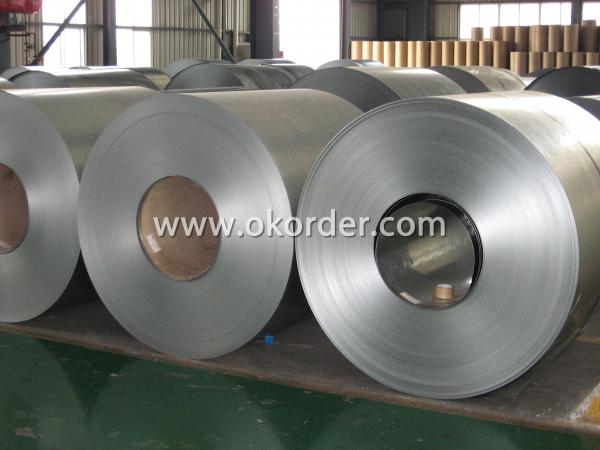

General Information Of Aluzinc Steel Coil- JIS G3321

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

|

Thickness 0.23-1.2mm (BMT) |

|

Zinc Coating 80-275g/m2 |

|

Color According to RAL color fan |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Paint Polyester paint for topside, epoxy for reverse |

|

Standard JIS G 3312, ASTM A755M, EN 10169 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel Coil- JIS G3321

|

C |

Si |

Mn |

P |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

Technical Data Of Aluzinc Steel Coil- JIS G3321

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Reverse Impact |

9J |

|

T-bending |

≥2T |

|

Pencil Hardness |

≥2H |

|

Duration Of Salt Spray Test |

500 H |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Aluzinc Steel Coil- JIS G3321

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery Of Aluzinc Steel Coil- JIS G3321

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: How are steel coils used in the manufacturing of shock absorbers?

- Steel coils are commonly used in the manufacturing of shock absorbers as they provide the necessary strength and flexibility to absorb and dampen shocks and vibrations. These coils are typically placed inside the shock absorber to support the weight of the vehicle and absorb the impact caused by uneven road surfaces. The coiled steel springs compress and expand to absorb the energy from the shocks, ensuring a smoother and more comfortable ride for the vehicle occupants.

- Q: How is steel sustainable as a building material?How is wood sustainable as a building material?

- Wood as it comes from trees which are in nature.

- Q: What are the common methods of packaging steel coils for international shipping?

- Various techniques are employed to package steel coils for international shipment in order to guarantee their safety and security during transit. One approach involves the utilization of wooden crates. Steel coils are positioned on wooden pallets and fastened with steel bands or straps. Next, wooden boards or plywood are placed over the coils and firmly attached with nails or screws to create a robust crate. This method ensures exceptional protection against damage and guarantees that the coils remain fixed in place during transportation. Another option is to employ steel frames or skids. Steel coils are positioned on specially designed steel skids or frames that can support the weight and shape of the coils. These coils are then secured to the skids or frames using steel bands or straps. This method offers a high level of stability and protection, making it particularly suitable for larger or heavier coils. In addition to wooden crates and steel frames, steel coils can also be packaged using steel containers or shipping containers. These containers are specifically designed to transport heavy or bulky items and provide a secure and protective environment for the coils. The coils are loaded into the container and secured with steel bands or straps to prevent movement during transit. Regardless of the chosen packaging method, it is crucial to ensure that the steel coils are adequately shielded from moisture, corrosion, and other potential hazards. This may involve the use of moisture-resistant materials such as plastic or wax paper, as well as the application of protective coatings or wraps. In summary, the common methods of packaging steel coils for international shipping include wooden crates, steel frames or skids, and steel containers. The selection of these methods depends on factors such as the size, weight, and specific requirements of the coils, with the ultimate goal of providing maximum protection and security during transit.

- Q: What are the common methods of joining steel coils together?

- The common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), and adhesive bonding.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- Not a chance. Stresses that are strong enough to crack solid steel would snap JB weld like a matchstick! JB is NOT a substitute for actual welding. Steel is more than 20 times stronger; or in other words, JB is 20 times weaker than the steel in your chair. JB is good for applications where the parts to be joined aren't constantly going to be under stress. For wood or plastics it works OK, for steel, not so much. Your best bet is to take the chair to a professional welding shop. If they want to charge you more than $15-$20; go somewhere else, they could weld that in less than a minute.

- Q: How are steel coils tested for tensile strength?

- Steel coils are typically tested for tensile strength using a method called tensile testing. This involves subjecting a sample of the steel coil to a controlled pulling force until it breaks. The force required to break the sample is then measured, providing an accurate measure of the steel's tensile strength.

- Q: What are the different types of steel coil surface treatments?

- The different types of steel coil surface treatments include hot-dip galvanizing, electro-galvanizing, organic coating, and pickling and oiling.

- Q: How are steel coils inspected?

- Steel coils are inspected using various methods such as visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help identify any defects, irregularities, or damages in the steel coils, ensuring their quality and suitability for further processing or use.

- Q: I just bought a dpms ar15 and it says if I shoot steel cases (laquer coated) or foreign ammo it voids the warranty. But before I knew this I bought 200 rounds of Russian steel cased anmo. Think I should just shoot there two hundred and not buy anymore? Some people say all they shoot is steel cased ammo and have no problemAny advice is appreciated

- Steel Case Ammo

- Q: How are steel coils used in the manufacturing of wind turbines?

- Steel coils are used in the manufacturing of wind turbines to create various components such as the tower, nacelle, and rotor blades. The high-strength steel coils are shaped and welded to form the tower, providing the necessary structural support for the entire turbine. Additionally, the steel coils are used to fabricate the nacelle, which houses the generator and other critical components. Moreover, steel coils are used in the manufacturing of rotor blades, providing strength and stability to harness wind energy efficiently. Overall, steel coils play a crucial role in the construction of wind turbines, ensuring their durability and performance.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Southern Asia; America; South America; Eastern Europe |

| Company Certifications | ISO 9000 ISO 14000 OHSAS 18000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Sell Aluzinc Steel Coil-JIS G3321

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- -

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords