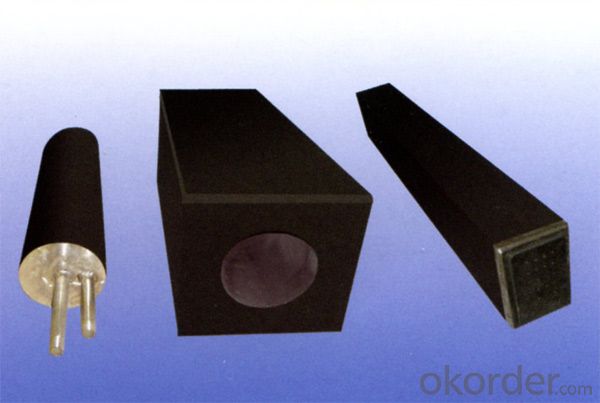

Refractory Brick purging plug for BOF and EAF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

purging plug Raw materials

Ladle permeable brick has been in the leading position in domestic and abroad over years. We have developed the series of corundum, chromium corundum, low silicon chromium corundum and corundum spinel one after another.

Customized purging plug

They can be designed and produced types of straight hole, directional slit, directional labyrinth, girth shape and interior and exterior integral split etc according to users’ request. Permeable flow rate of products can be designed upon customers’ request and can be adjusted in a wide range. The blowing opening rate is high.

purging plug Characters

Continuous casting Ladle Porous Block

High alumina and MgO content

High stability.

Thermal shock resisitance.

High life span

purging plug Physical and chemical indexes

Brand | TQZ-1 | TQZ-2 | |

Chemical composition/%,≥ | Al2O3+Cr2O3 | 92 | |

Al2O3+MgO | 92 | ||

Bulk density g/cm³ ≥ | 3 | 3 | |

Crushing strength /Mpa≥ | 1500°C×3h | 100 | 80 |

Modulus of rupture/Mpa≥ | 1500°C×3h | 20 | 15 |

Firing linear change % | 1500°C×3h | 0~+0.3 | 0~+0.4 |

Penetration gas flux (0.4Mpa)/m³ h-1 | 12~60 | 12~60 | |

Factory productivity

Based on 180,000 TON annual productivity and advanced production equipment, we have build deep cooperation relationship with Vietnam, Nigeria, Tailand, Saudi Arabia, Iran, Turkey, etc.

- Q: How do monolithic refractories contribute to the overall efficiency of iron and steel production?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of iron and steel production. These refractories, which are made from a single material, provide exceptional thermal insulation, resistance to high temperatures, and excellent mechanical strength. By lining the furnaces, ladles, and other equipment used in the production process, monolithic refractories help in maintaining and regulating the required high temperatures for melting, refining, and shaping iron and steel. This insulation reduces heat loss, minimizes energy consumption, and ensures a more efficient and cost-effective production process. Additionally, the mechanical strength of monolithic refractories allows for better protection against wear and tear, resulting in increased equipment lifespan and reduced downtime for repairs and maintenance. Overall, the use of monolithic refractories significantly contributes to the efficiency, productivity, and sustainability of the iron and steel production industry.

- Q: How do monolithic refractories contribute to the reduction of heat loss in iron and steel furnaces?

- Reducing heat loss in iron and steel furnaces is a crucial role played by monolithic refractories. These refractories are specifically designed to create a seamless lining throughout the furnace, eliminating any joints or seams that could result in thermal leaks. Monolithic refractories effectively contribute to heat loss reduction in two ways. Firstly, they possess excellent thermal insulation properties that restrict the transfer of heat from the furnace to its surroundings. With their low thermal conductivity, they effectively maintain the high temperatures required for efficient iron and steel production within the furnace, while minimizing heat loss to the surrounding environment. Secondly, monolithic refractories act as a protective barrier, preventing the escape of hot gases and molten metal. This barrier ensures the integrity of the furnace lining, preventing any gaps or cracks that could allow heat to escape. By creating a tight and continuous lining, monolithic refractories significantly reduce heat loss by keeping the heat contained within the furnace. Furthermore, monolithic refractories exhibit a high resistance to thermal shock and erosion, which are common challenges faced in iron and steel furnaces. These refractories can withstand rapid temperature changes, preventing sudden cracks or failures that could result in heat loss. Additionally, they are resistant to the corrosive effects of molten metal and hot gases, guaranteeing the longevity of the lining and preserving its insulating properties over time. To summarize, monolithic refractories contribute to the reduction of heat loss in iron and steel furnaces through their exceptional thermal insulation properties, ability to provide a continuous lining, resistance to thermal shock and erosion, and protection against corrosive substances. By minimizing heat loss, these refractories optimize energy efficiency and productivity in the furnace, leading to cost savings and improved overall performance in the iron and steel industry.

- Q: How do monolithic refractories withstand high temperatures in iron and steel production?

- Monolithic refractories, which are tailored for iron and steel production, have the capability to endure the formidable temperatures involved. Unlike traditional brick refractories that are built brick by brick, monolithic refractories are made from a single piece or material. The resilience of monolithic refractories against high temperatures is due to their distinctive composition and structure. They are crafted from top-notch raw materials, such as alumina, magnesia, silica, and carbon, which possess high melting points and exceptional heat resistance. To shape and strengthen the monolithic refractory, it is commonly mixed with a binder like clay or cement. This binder assists in binding the refractory particles together and provides the necessary structure to withstand thermal stresses. Moreover, the mixture can include various additives to further enhance the refractory properties. Throughout the iron and steel production process, monolithic refractories encounter extreme temperatures, rapid heating and cooling cycles, and chemical reactions with molten metals and slag. Nevertheless, the unique composition and structure of monolithic refractories enable them to withstand these harsh conditions. The high melting point materials utilized in monolithic refractories prevent them from melting or deforming under the intense heat of iron and steel production. These materials exhibit excellent thermal conductivity, effectively transferring heat away from hot surfaces and preventing overheating and damage. Furthermore, the binders and additives in monolithic refractories enhance their resistance to thermal shock, which arises from sudden temperature changes. This resistance is vital in iron and steel production since the refractories are frequently exposed to extreme temperature differentials. Lastly, the monolithic nature of these refractories eliminates the presence of joints and gaps commonly found in traditional brick refractories. The absence of joints minimizes the risk of heat leakage and infiltration of molten metal or slag, ensuring a more efficient and durable lining. In conclusion, monolithic refractories are specifically engineered to endure the high temperatures involved in iron and steel production. Their composition, structure, and unique properties enable them to withstand extreme heat, rapid temperature changes, chemical reactions, and thermal stresses, making them essential components in the manufacturing of iron and steel.

- Q: How are monolithic refractories installed and repaired in iron and steel plants?

- Monolithic refractories in iron and steel plants are typically installed through a process called gunning, where a specialized gunning machine is used to spray the refractory material onto the desired surface. The refractory material is mixed with water or a bonding agent to form a dense and durable lining. In terms of repairs, damaged or worn-out monolithic refractories are typically removed by mechanical means, such as jackhammers or pneumatic tools. The damaged area is then cleaned and prepared before new refractory material is applied using the gunning method. In some cases, patching materials may be used to repair smaller areas of damage. Overall, the installation and repair of monolithic refractories in iron and steel plants require skilled technicians and specialized equipment to ensure the optimum performance and longevity of the refractory lining.

- Q: How do monolithic refractories handle thermal expansion and contraction?

- Monolithic refractories handle thermal expansion and contraction by their ability to withstand high temperatures and adapt to changes in size without cracking or breaking. They are designed to have low thermal conductivity, which helps to minimize stress caused by thermal cycling. Additionally, they are often composed of materials with high refractoriness and high thermal shock resistance, allowing them to expand and contract with minimal damage.

- Q: How do monolithic refractories resist thermal shock in the iron and steel industry?

- Monolithic refractories are specifically designed to resist thermal shock in the iron and steel industry. This is primarily achieved through their unique composition and structure. Firstly, monolithic refractories are made from high-quality raw materials, such as alumina, magnesia, and silica, which have excellent thermal properties. These materials are carefully selected to provide a high melting point, low thermal conductivity, and good thermal expansion characteristics. Secondly, the manufacturing process of monolithic refractories involves precise control of the grain size distribution and the addition of bonding agents. This results in a dense and homogeneous structure, which enhances their resistance to thermal shock. The bonding agents also play a crucial role in enhancing the refractory's strength and integrity. Additionally, monolithic refractories are often formulated with additives that provide increased resistance to thermal shock. These additives can include zirconia, silicon carbide, or graphite, which improve the refractory's ability to withstand rapid temperature changes. Moreover, monolithic refractories are designed to have low porosity, reducing the penetration of molten metal or slag into the material. This helps to prevent the formation of cracks and spalling, which can occur due to thermal shock. Furthermore, monolithic refractories are often applied as a lining or coating on the surface of the furnace or other equipment. This allows them to form a protective barrier, reducing direct exposure to extreme temperatures and thermal cycling. Overall, the combination of high-quality raw materials, careful manufacturing processes, additives, low porosity, and proper application techniques make monolithic refractories highly resistant to thermal shock in the iron and steel industry. They can withstand rapid temperature changes, prevent cracks, and maintain their structural integrity, ensuring reliable and efficient operation of furnaces and other equipment in this demanding industry.

- Q: How do monolithic refractories withstand mechanical stress in the iron and steel industry?

- Monolithic refractories are designed to withstand mechanical stress in the iron and steel industry through their unique composition and properties. These refractories are made up of a single, uniform structure, as opposed to traditional brick-like refractories that consist of multiple pieces. This monolithic structure provides several advantages in terms of mechanical stress resistance. Firstly, monolithic refractories possess a higher strength and density compared to traditional refractories. This allows them to better withstand the mechanical forces exerted during various processes in the iron and steel industry, such as the movement of molten metal, the impact of scrap materials, or the pressure from gases and liquids. Their superior strength and density help prevent cracking, deformation, or failure under these stress conditions. Additionally, monolithic refractories offer excellent thermal shock resistance, which is crucial in the iron and steel industry. The rapid heating and cooling cycles experienced in processes like steelmaking or iron casting can cause thermal stress on refractories. However, the monolithic structure of these refractories allows for better thermal conductivity and expansion, reducing the risk of thermal shock damage. This ability to withstand thermal stress contributes to their overall mechanical stress resistance. Moreover, monolithic refractories can be customized and applied on-site, providing a seamless lining that eliminates joints or weak spots. This seamless application ensures a more uniform distribution of stress and prevents the formation of cracks or gaps that could weaken the refractory lining. By eliminating these vulnerabilities, monolithic refractories enhance their ability to resist mechanical stress in the demanding conditions of the iron and steel industry. In conclusion, monolithic refractories withstand mechanical stress in the iron and steel industry through their high strength and density, superior thermal shock resistance, and seamless application. These properties enable them to endure the intense mechanical forces encountered during various processes, ensuring the longevity and efficiency of refractory linings in this demanding industry.

- Q: How do monolithic refractories resist chemical attacks from molten metals and slag?

- Monolithic refractories are engineered to withstand chemical attacks caused by molten metals and slag. They possess various essential qualities that enable them to endure such harsh conditions. To begin with, monolithic refractories comprise top-notch materials with exceptional chemical resistance. These materials, including alumina, magnesia, and chrome, have a high melting point and remain stable even when exposed to extreme temperatures and corrosive substances. This chemical stability ensures that the refractory maintains its integrity and structural strength when in contact with molten metals and slag. Moreover, monolithic refractories have a compact and dense structure. This microstructure serves as a barrier, preventing molten metals and slag from penetrating the refractory material. By limiting the contact between the corrosive substances and the refractory, the dense structure reduces the likelihood of chemical reactions and erosion, thereby enhancing the refractory's resistance to chemical attacks. Additionally, monolithic refractories often contain additives and binders that enhance their chemical resistance. These additives form a protective layer on the refractory surface, acting as a shield against chemical attacks. They can also react with certain corrosive substances, forming stable compounds that further inhibit the penetration and corrosion of the refractory material. Furthermore, monolithic refractories are designed to have minimal porosity. This low porosity minimizes the absorption of molten metals and slag, preventing them from infiltrating the refractory and causing damage. By reducing the permeability of the material, the refractory can maintain its structural integrity and resist chemical attacks for extended periods. In conclusion, monolithic refractories withstand chemical attacks from molten metals and slag due to their high-quality materials, dense structure, additives, and low porosity. These combined properties enable the refractories to endure aggressive environments and maintain their performance and longevity in industrial applications.

- Q: How are monolithic refractories different from conventional refractories?

- Monolithic refractories are different from conventional refractories in that they are composed of a single, continuous structure, whereas conventional refractories are made up of multiple individual bricks or shapes. Monolithic refractories offer greater flexibility in terms of installation, as they can be easily shaped and molded to fit various applications. Additionally, monolithic refractories usually have better thermal shock resistance and are more resistant to cracking, making them more durable and long-lasting compared to conventional refractories.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish lining systems?

- The efficiency of ladle and tundish lining systems is greatly enhanced by monolithic refractories in several ways. Firstly, these refractories are made from a single piece of material, eliminating the need for joints or seams. This seamless construction guarantees a lack of weak points in the lining system, reducing the chances of molten metal leakage or infiltration. Moreover, monolithic refractories possess exceptional thermal insulation properties. With their low thermal conductivity, they are able to withstand high temperatures without transferring heat to the surrounding environment. This insulation capability minimizes heat loss from the ladle or tundish, resulting in improved heat retention and energy efficiency. Additionally, it ensures that the desired temperature of the molten metal is maintained, preventing premature solidification and ensuring the necessary fluidity for casting. Furthermore, monolithic refractories exhibit outstanding resistance to chemical attacks caused by molten metal and slag. Their excellent corrosion resistance properties ensure the durability and integrity of the lining, even in the face of aggressive chemical reactions. This resistance to corrosion prolongs the lifespan of the lining system, reducing the need for frequent maintenance and replacement, thereby increasing overall efficiency and reducing downtime. Another advantage of monolithic refractories is their easy installation. Unlike traditional brick or block linings, monolithic refractories can be applied as a single, uniform layer, simplifying and speeding up the installation process. This reduces the time required for lining repairs or replacements, minimizing disruptions to production and enhancing the overall operational efficiency of ladles and tundishes. In conclusion, monolithic refractories enhance the efficiency of ladle and tundish lining systems through their seamless construction, excellent thermal insulation, superior corrosion resistance, and easy installation. These characteristics ensure improved heat retention, reduced heat loss, increased durability, and minimized downtime, resulting in enhanced productivity and cost-effectiveness for metal casting processes.

Send your message to us

Refractory Brick purging plug for BOF and EAF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords