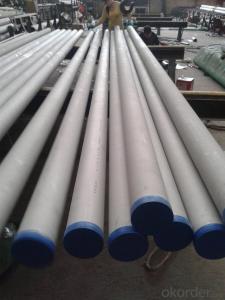

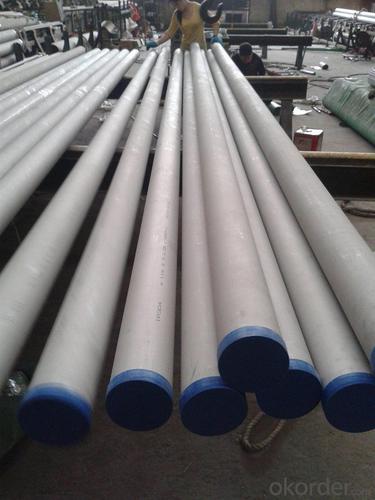

Ratnamani Stainless Steel Pipes - High Quality Stainless Steel Tubes

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | JIS,AISI,ASTM,GB,DIN,CE | Place of Origin: | Guangdong China (Mainland) | Brand Name: | QX |

| Model Number: | 201/202/304/316/316L/430 | Type: | Welded | Steel Grade: | 300 Series |

| Application: | Decoration,construction, upholstery | Certification: | ISO | Welding Line Type: | ERW |

| Thickness: | 0.3mm to 3.0mm | Outer Diameter: | 9.53mm to 159mm | Polish: | Satin,Bright or Mirror |

| Grade: | 201,202,301,304,316,316l,430 ect. | Length: | In gernal 5.8m/6m or as customer request | Process method: | Hot rolled |

| Test: | Squash test, water pressure test,extended test,crystal rot test etc. | Production Standard: | ASTM A554 | Materials: | SUS 304, 201, 316, 316L,430 ect |

| OD tolerance: | + / - 0.15mm | Thickness tolerance: | +/- 10% | Length tolerance: | +/- 10mm |

Packaging & Delivery

| Packaging Detail: | Every tube is sleeved in plastic bag individually, and then several tubes are packed by weaving bag, which is seaworthy. Or 50kg/bundle, 500kg/bundle.We can pack as clients' requirement. |

| Delivery Detail: | 25 - 35 days for a full container. |

Specifications

Stainless Steel Pipe:

1.201,202,301,304,316L,430,etc

2.OD:6mm-159mm

3.Thickness:0.25mm-3.5mm

4.Finish:Mirror,Satin,Hairline

- Q:What is the hardness of stainless steel pipes?

- The hardness of stainless steel pipes can vary depending on the specific grade and treatment of the steel. Stainless steel pipes have a range of hardness levels, usually measured using the Rockwell scale or the Brinell scale. The hardness of stainless steel pipes is typically higher than that of other types of steel due to the alloying elements, such as chromium and nickel, which provide increased resistance to corrosion and wear. Generally, stainless steel pipes have a hardness level that falls within the range of 75 to 180 on the Rockwell scale or 150 to 300 on the Brinell scale. However, it's important to note that the hardness can also be influenced by factors such as heat treatment, welding, and cold working processes.

- Q:What is the maximum wall thickness for stainless steel pipes?

- The maximum wall thickness for stainless steel pipes can vary depending on various factors such as the specific grade of stainless steel, the manufacturing process, and the intended application. However, in general, stainless steel pipes typically have a maximum wall thickness of around 40 millimeters.

- Q:Can stainless steel pipes be used in the food processing industry?

- Yes, stainless steel pipes are commonly used in the food processing industry due to their corrosion resistance, hygienic properties, and durability. Stainless steel is non-reactive, does not leach chemicals into food, and can withstand high temperatures and frequent cleaning, making it an ideal material for transporting food and beverages safely.

- Q:Can stainless steel water pipes be cooled and bent?

- Stainless steel pipe is a kind of hollow long strip round steel, mainly used in petroleum, chemical, medical, food, light industry, machinery, instrument and other industrial pipeline and mechanical structure parts.

- Q:What are the connecting methods of stainless steel pipes for indoor water pipes?

- Card convex features: easy installation, the connection is not deformed inside and outside, belong to live connection, easy maintenance. Scope of application: cold water system, pipe direct drinking water system, water treatment equipment system. The installation is more suitable, mainly taking into account the replacement of the sealing ring later, the hot water system should be avoided as far as possible. The advantage of the connection is that the installation is simple, convenient and easy to maintain, and the sealing ring in the pipe needs replacing when aging, and the utility model is relatively simple and convenient, and the nut can be replaced as long as the nut is unscrewed. The disadvantage is that the applicable situation is single, in the hot water system sealing ring aging is more prominent, higher cost. Concealed piping and hot water systems are generally not recommended.

- Q:What is the difference between seamless and high-frequency welded stainless steel pipes?

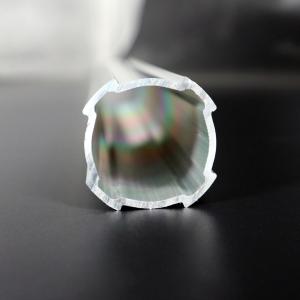

- Two different types of pipes used in various applications are seamless stainless steel pipes and high-frequency welded stainless steel pipes. Seamless stainless steel pipes undergo a process called seamless pipe manufacturing. This involves heating and piercing a solid billet to create a hollow tube. The absence of seams or joints in seamless pipes makes them ideal for applications that require high pressure, high temperature, or corrosive environments. Their uniform composition and lack of welding contribute to their superior strength and reliability. In contrast, high-frequency welded stainless steel pipes are manufactured using high-frequency welding. This process includes passing a flat strip of stainless steel through rollers to form a tube shape. The edges of the strip are heated with high-frequency electrical currents and fused together, resulting in a solid pipe with a visible welded seam. Although both types of pipes are made from stainless steel, there are some differences between them. The manufacturing process is a significant distinction. Seamless pipes are created without any welding, resulting in a seamless and jointless pipe. On the other hand, high-frequency welded pipes have a visible welded seam along their length. Another difference lies in the strength and reliability. Seamless pipes, due to their uniform composition and absence of welding, offer higher strength and reliability compared to high-frequency welded pipes. This makes seamless pipes more suitable for applications that involve high pressure, high temperature, or corrosive environments. Moreover, the production cost of seamless pipes is generally higher than that of high-frequency welded pipes. The seamless pipe manufacturing process requires more complex machinery and additional steps, leading to higher production costs. Conversely, high-frequency welded pipes involve a simpler and more cost-effective manufacturing process. In summary, the main distinctions between seamless and high-frequency welded stainless steel pipes revolve around their manufacturing process, strength, and cost. Seamless pipes are made without any welding, providing higher strength and reliability at a higher cost. High-frequency welded pipes have a visible welded seam but are more cost-effective. The choice between the two types of pipes depends on the specific requirements of the application and the available budget.

- Q:What is the difference between 304J1 and 316J1 stainless steel pipes?

- The main difference between 304J1 and 316J1 stainless steel pipes lies in their composition and properties. 304J1 stainless steel is a variant of 304 stainless steel, which contains a higher percentage of manganese to enhance its formability and reduce the risk of strain hardening during fabrication. This makes it more suitable for certain applications where deep drawing or severe bending is required. However, it is less corrosion-resistant compared to 316J1 stainless steel. On the other hand, 316J1 stainless steel is a variant of 316 stainless steel, which contains a higher percentage of nitrogen to improve its strength and corrosion resistance. It also has slightly better resistance to pitting and crevice corrosion in chloride environments. Therefore, 316J1 stainless steel pipes are often preferred in applications where higher corrosion resistance is required, such as marine environments or chemical processing plants. In summary, while both 304J1 and 316J1 stainless steel pipes are suitable for various applications, the choice between them depends on the specific needs of the project, including the level of corrosion resistance required and the fabrication processes involved.

- Q:What's the difference between stainless steel 304 and stainless steel 202?

- 202 stainless steel is one of the 200 series stainless steel, the national standard model is 1Cr18Mn8Ni5N. 200 series stainless steel is low nickel, high manganese stainless steel, nickel content, manganese content of about 8%, is a nickel type stainless steel.

- Q:Can stainless steel pipes be used for fire sprinkler systems?

- Yes, stainless steel pipes can be used for fire sprinkler systems.

- Q:Can stainless steel pipes be insulated with polycaprolactone?

- Stainless steel pipes can indeed be insulated with polycaprolactone. Polycaprolactone, also known as PCL, is a thermoplastic polymer that has excellent thermal insulation properties. It has a low thermal conductivity, which makes it an effective choice for insulating pipes and preventing heat loss or gain. Additionally, PCL is also resistant to moisture and chemicals, making it suitable for various environments and applications. When applied as insulation on stainless steel pipes, polycaprolactone can help maintain the desired temperature, reduce energy consumption, and prevent condensation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ratnamani Stainless Steel Pipes - High Quality Stainless Steel Tubes

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords