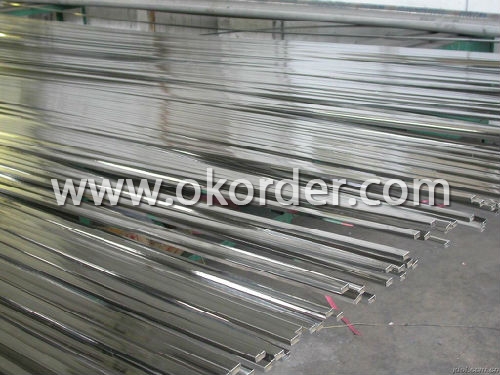

304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304 Stainless Steel Flats

1.Standard:

AISI, GB, JIS, ASTM, DIN, EN

2. Grade:

1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:

3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application:

These products are widely supplied to areas of machine made industry, chemical industry, shipping industry,architecture, food industry, household products etc

Name | Stainless Steel Flat Bar | ||||||||

Material | 201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

Standard | JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

Length | 6m,5.8m,4m as required | ||||||||

Application | kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

Payment terms | L/C,T/T,Western Union,or as required. | ||||||||

MOQ | As required | ||||||||

Packing | Export standard package | ||||||||

Certificate | ISO/SGS | ||||||||

Contact | If you are interested in our products,please feel free to contact me. |

- Q: Are stainless steel pipes suitable for air conditioning systems?

- Yes, stainless steel pipes are suitable for air conditioning systems. They offer excellent corrosion resistance, durability, and can withstand high temperatures and pressure levels commonly found in air conditioning systems. Stainless steel pipes also ensure clean air quality and are easy to maintain, making them a reliable choice for air conditioning installations.

- Q: Can stainless steel pipes be used for swimming pool systems?

- Indeed, swimming pool systems can utilize stainless steel pipes. The reason why stainless steel is a favored option for swimming pool piping lies in its remarkable ability to resist corrosion and its durability. It is impervious to rust and can endure exposure to chlorine, saltwater, and other chemicals frequently employed in pool systems. Moreover, stainless steel pipes possess considerable strength, rendering them apt for managing the pressure and water flow within swimming pool systems. Furthermore, stainless steel pipes are simple to clean and maintain, guaranteeing a prolonged lifespan for the pool system.

- Q: Are stainless steel pipes resistant to hydrogen embrittlement?

- Yes, stainless steel pipes are generally resistant to hydrogen embrittlement. Hydrogen embrittlement is a phenomenon where hydrogen can penetrate into the structure of certain metals, causing them to become brittle and susceptible to cracking or failure. Stainless steel, however, has a high resistance to hydrogen embrittlement due to its unique composition. Stainless steel is primarily composed of iron, chromium, and other alloying elements such as nickel and molybdenum. The presence of chromium in stainless steel forms a passive oxide layer on the surface, which provides excellent corrosion resistance and acts as a barrier to prevent hydrogen from diffusing into the metal. Additionally, stainless steel pipes are often manufactured using specific grades (e.g., austenitic or duplex stainless steels) that exhibit even higher resistance to hydrogen embrittlement. These grades have a higher content of alloying elements, which further enhances their resistance to hydrogen attack. However, it is important to note that under certain conditions, such as high temperatures and high-pressure environments, stainless steel can still be susceptible to hydrogen embrittlement. Therefore, it is crucial to consider the specific application and operating conditions when selecting stainless steel pipes to ensure their resistance to hydrogen embrittlement.

- Q: Can stainless steel pipes be used in the oil and gas industry?

- Yes, stainless steel pipes can be used in the oil and gas industry. Stainless steel pipes offer several advantages that make them suitable for use in this industry. Firstly, stainless steel has high corrosion resistance, which is crucial for withstanding the harsh environments and corrosive substances present in the oil and gas industry. This resistance to corrosion helps to prevent leaks and ensures the integrity of the pipes, promoting safety and reliability. Additionally, stainless steel pipes have excellent strength and durability, allowing them to withstand high pressures and temperatures that are often encountered in oil and gas operations. Moreover, stainless steel is non-reactive, meaning it does not contaminate the oil or gas being transported, ensuring the purity and quality of the product. Overall, the superior properties of stainless steel make it a preferred choice for oil and gas industry applications, providing a reliable and long-lasting solution.

- Q: What is the difference between seamless and spiral welded stainless steel pipes?

- The main difference between seamless and spiral welded stainless steel pipes lies in their manufacturing process. Seamless pipes are formed by piercing a solid billet of stainless steel and then rolling it into a pipe shape, resulting in a continuous and uniform structure. On the other hand, spiral welded pipes are made by rolling a coil of stainless steel into a spiral shape and welding the edges together. This creates a noticeable weld seam along the length of the pipe. While seamless pipes are generally considered to have superior strength and aesthetic appeal due to their uninterrupted structure, spiral welded pipes are often more cost-effective and suitable for applications requiring larger diameters.

- Q: What is the difference between ERW and EFW stainless steel pipes?

- ERW (Electric Resistance Welded) stainless steel pipes are manufactured by rolling a flat steel into a cylindrical shape and then welding the edges together using electric resistance heat. On the other hand, EFW (Electric Fusion Welded) stainless steel pipes are produced by melting the edges of two steel plates or strips and then welding them together using an electric current. The main difference between ERW and EFW stainless steel pipes lies in the welding process, with ERW pipes having a smoother internal surface due to the absence of filler material, while EFW pipes have a slightly thicker weld seam. Additionally, EFW pipes are generally used for larger diameters and thicker walls, whereas ERW pipes are commonly used for smaller diameters and thinner walls.

- Q: What is the difference between 2205 and 316L stainless steel pipes?

- The chemical composition and intended applications distinguish 2205 stainless steel pipes from 316L stainless steel pipes. 2205 stainless steel, a duplex stainless steel, consists of two phases - austenite and ferrite. This composition grants it exceptional corrosion resistance, particularly in environments with high chloride content. Industries such as oil and gas, chemical processing, and marine applications commonly employ 2205 stainless steel pipes due to their corrosion resistance and high strength requirements. On the other hand, 316L stainless steel, an austenitic stainless steel, contains lower carbon content compared to other 300 series grades. It exhibits good corrosion resistance, particularly to acids and chloride solutions, making it suitable for various applications like food processing, pharmaceuticals, and medical equipment manufacturing. Regarding mechanical properties, 2205 stainless steel pipes generally possess higher tensile strength and yield strength than 316L stainless steel pipes. Consequently, 2205 pipes are more appropriate for applications necessitating greater strength and load-bearing capabilities. It is vital to acknowledge that both grades of stainless steel pipes possess their respective advantages and limitations. The selection between 2205 and 316L stainless steel pipes depends on the specific application, environmental conditions, and budgetary considerations. Seeking guidance from a materials engineer or stainless steel expert can aid in determining the most suitable grade for a particular project.

- Q: What is the weight of stainless steel pipes?

- The weight of stainless steel pipes can vary depending on the size, thickness, and length of the pipes. It is important to consider these factors in order to determine the exact weight of stainless steel pipes.

- Q: How do you prevent contamination in stainless steel pipes?

- To prevent contamination in stainless steel pipes, it is crucial to follow a few important steps. Firstly, regular cleaning and maintenance are essential. This involves using appropriate cleaning agents and techniques to remove any dirt, debris, or potential contaminants from the pipes. It is important to avoid using abrasive materials or harsh chemicals that can damage the stainless steel surface. Secondly, ensuring proper installation and sealing of the pipes is crucial. Any gaps or leaks in the connections can allow contaminants to enter the system. It is advisable to use high-quality fittings and seals to ensure a tight and secure connection. Thirdly, implementing a comprehensive filtration system can help prevent contamination. Filters can remove impurities such as sediments, particles, and other contaminants that may be present in the fluid or gas flowing through the pipes. Regularly inspecting and replacing these filters is important to maintain their efficiency. Additionally, regular inspection and monitoring of the pipes is essential. This includes checking for signs of corrosion, rust, or any other damage that can compromise the integrity of the pipes. Promptly addressing any issues that arise can prevent contamination and extend the lifespan of the stainless steel pipes. Lastly, it is crucial to establish and follow proper hygiene practices. This includes implementing procedures to minimize the introduction of contaminants during maintenance or repairs. It is also important to train personnel on proper handling techniques and the importance of maintaining cleanliness and hygiene when working with stainless steel pipes. By following these preventive measures, it is possible to minimize the risk of contamination in stainless steel pipes, ensuring the integrity and longevity of the system.

- Q: Can stainless steel pipes be coated?

- Stainless steel pipes have the capability to undergo coating procedures. Coating these pipes serves multiple purposes, such as bolstering their durability, preventing corrosion, providing insulation, and enhancing their aesthetics. There exist diverse options for coating stainless steel pipes, including epoxy coatings, polyurethane coatings, and fusion-bonded epoxy coatings. These coatings are applied to the surface of the stainless steel pipes using various techniques, such as spraying, dipping, or electrophoretic deposition. The selection of the appropriate coating relies on the specific requirements of the application and the environment in which the pipes will be utilized. By coating stainless steel pipes, their lifespan can be significantly extended and their performance can be improved, making them suitable for a wide range of industries including oil and gas, chemical, water treatment, and construction.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords