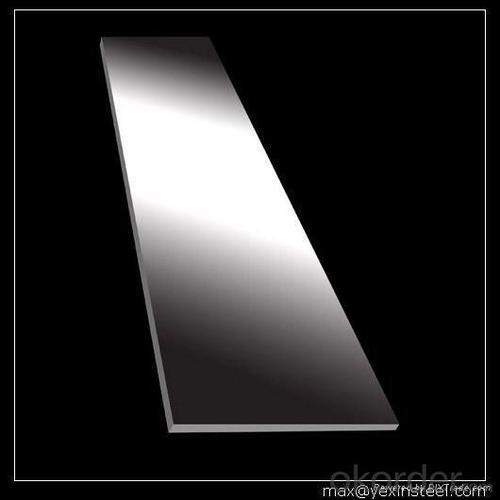

Stainless Steel Bright Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 2500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless Steel Bright Bar

Thickness: 3mm - 40mm

Width: 20mm - 120mm

Standard: ASTM A276/484M ,EN 10278/DIN 174

- Q: What is the cost of stainless steel pipes compared to other materials?

- The cost of stainless steel pipes tends to be higher compared to other materials such as PVC or carbon steel. Stainless steel is known for its durability, corrosion resistance, and high strength, which makes it a popular choice in various industries. However, these qualities come at a higher price point. Additionally, factors such as pipe dimensions, grade of stainless steel, and market fluctuations can also affect the overall cost.

- Q: Are stainless steel pipes suitable for food storage tanks?

- Stainless steel pipes are an excellent choice for food storage tanks due to their high suitability. They possess remarkable corrosion resistance, making them ideal for the storage of food and beverages. Unlike other materials, stainless steel pipes guarantee the safety and quality of the stored food as they do not release any harmful substances. Moreover, their easy maintenance and cleaning contribute to maintaining proper hygiene in food storage tanks. Additionally, stainless steel pipes are durable and capable of withstanding high temperatures, ensuring the longevity and reliability of the tanks. In conclusion, stainless steel pipes are the preferred option for food storage tanks due to their sanitary properties, corrosion resistance, and durability.

- Q: Can stainless steel pipes handle extreme weather conditions?

- Yes, stainless steel pipes are known for their excellent durability and resistance to extreme weather conditions. They can withstand high temperatures, heavy rains, strong winds, and even harsh chemicals without corroding or deteriorating. The inherent properties of stainless steel, such as its high strength, corrosion resistance, and heat resistance, make it an ideal choice for outdoor applications and extreme weather conditions. Stainless steel pipes can handle extreme heat and cold, as well as resist the effects of UV radiation and oxidation. These pipes are often used in industries such as oil and gas, chemical processing, construction, and marine applications, where they are subjected to harsh environments. Overall, stainless steel pipes are a reliable and long-lasting solution for handling extreme weather conditions.

- Q: Are stainless steel pipes resistant to pitting?

- Yes, stainless steel pipes are generally resistant to pitting. The high chromium content in stainless steel creates a protective oxide layer on the surface, which helps prevent pitting corrosion. However, the resistance to pitting can vary depending on the specific grade of stainless steel and the conditions in which it is used.

- Q: Can stainless steel pipes be laser welded?

- Yes, stainless steel pipes can be laser welded. Laser welding is a highly efficient and precise method of joining metals, including stainless steel. It involves the use of a high-powered laser beam to melt and fuse the edges of the pipes together. Laser welding is commonly used in various industries, such as automotive, aerospace, and construction, due to its ability to create strong and durable welds with minimal distortion. The process is particularly well-suited for stainless steel, as it offers excellent control over the heat input, resulting in a narrow and well-defined weld zone. Additionally, laser welding can be automated, making it a cost-effective and time-efficient solution for joining stainless steel pipes.

- Q: Are stainless steel pipes resistant to fire?

- Indeed, stainless steel pipes possess remarkable fire resistance. Renowned for its exceptional heat-resistant qualities, stainless steel emerges as an appropriate material for situations involving elevated temperatures. In the face of fire, stainless steel pipes maintain their robustness and structural stability, thereby reducing the potential for collapse or malfunction. This fire resistance stems from the elevated melting point of stainless steel, which enables it to endure temperatures surpassing those commonly encountered in fires. Moreover, stainless steel does not fuel the propagation of flames, rendering it a secure option for fire protection and containment systems.

- Q: Are stainless steel pipes resistant to UV radiation?

- UV radiation does not affect stainless steel pipes as they are resistant to it. Stainless steel is renowned for its exceptional ability to resist corrosion, including the harmful impacts of UV radiation. When exposed to UV radiation, stainless steel develops a passive oxide layer on its surface, which acts as a shield to prevent further harm. This oxide layer effectively prevents degradation, discoloration, and loss of mechanical properties that can arise from exposure to UV radiation. Consequently, stainless steel pipes are an ideal option for outdoor or exposed uses where UV radiation is a concern.

- Q: How about stainless steel 2520 and 316?

- 2520 stainless steel (310S) austenitic chromium nickel stainless steel has good oxidation resistance, corrosion resistance, because of higher content of chromium and nickel content, which has high temperature creep strength, can continuously work under high temperature, good heat resistance. For Ni (Ni), chromium (Cr) content is high, with good oxidation resistance, corrosion resistance, acid and salt, high temperature performance, high temperature resistant steel dedicated to the manufacture of electric furnace tube and so on, increase the amount of carbon austenitic stainless steel, due to the solid solution strengthening effect to the strength improved, chemical composition characteristics of austenitic stainless steel is chrome, nickel based addition of molybdenum and tungsten, niobium and titanium elements, as its face centered cubic structure, and strength and high creep strength at high temperature.

- Q: What is the internal roughness of stainless steel pipes?

- The internal roughness of stainless steel pipes refers to the texture or surface finish on the inner walls of the pipe. It is a measure of the irregularities or bumps present on the internal surface. The roughness is usually quantified by measuring the average height of these irregularities, typically expressed as Ra (arithmetical mean deviation of the profile) or Rz (maximum height of the profile). Stainless steel pipes are known for their smooth and corrosion-resistant properties, which make them suitable for various applications in industries such as oil and gas, food processing, pharmaceuticals, and chemicals. The internal roughness of stainless steel pipes is typically low, resulting in minimal frictional resistance to fluid flow and improved hygienic properties. The internal roughness can vary depending on the manufacturing process, the grade of stainless steel, and the intended application. Stainless steel pipes can be manufactured with different surface finishes, such as pickled, annealed, or polished, which can affect the internal roughness. Polished surfaces generally have lower roughness values, providing smoother flow and minimizing the risk of contamination in applications that require high cleanliness standards. It is important to consider the internal roughness of stainless steel pipes when designing systems that involve fluid flow, as it can impact the pressure drop, flow rate, and overall efficiency. The roughness value is often taken into account in fluid dynamics calculations, such as determining the friction factor in pipe flow equations. To ensure the desired internal roughness, stainless steel pipes are often subjected to post-processing treatments, such as electropolishing or mechanical polishing, which can further reduce the roughness and improve the surface finish. These treatments enhance the performance and longevity of stainless steel pipes in critical applications where minimal frictional resistance, high cleanliness, and corrosion resistance are essential.

- Q: Are stainless steel pipes resistant to caustic environments?

- Stainless steel pipes possess exceptional resistance against caustic environments. Stainless steel is widely recognized for its ability to withstand corrosion, making it an ideal choice for usage in diverse harsh settings, including those containing caustic substances. The abundant presence of chromium within stainless steel forms a protective and inactive layer on the surface of the pipes, serving as a defense mechanism that prevents corrosion and upholds the integrity of the material. This layer serves as a formidable barrier, effectively safeguarding the steel from the damaging impact of caustic substances like acids, alkalis, and other chemicals. Hence, stainless steel pipes are an unparalleled option for applications that involve exposure to caustic environments, guaranteeing exceptional endurance, longevity, and dependability under such circumstances.

Send your message to us

Stainless Steel Bright Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 2500MT Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords