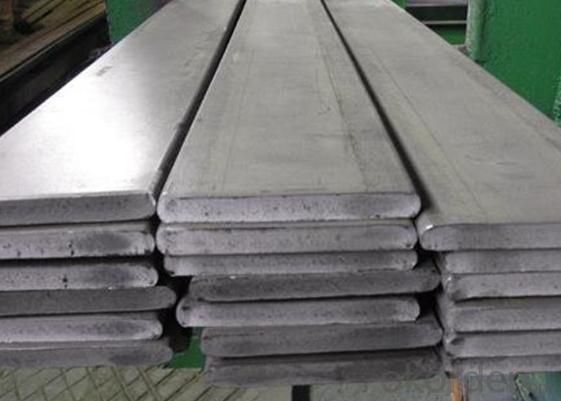

Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

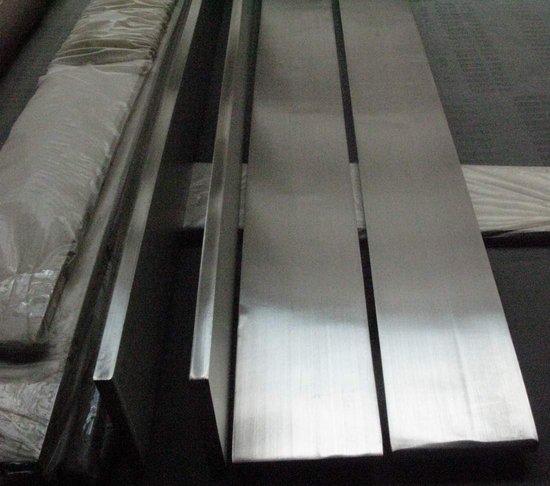

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1 Ton

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Size |

Thickness (mm) | |||||||||||

|

Width (mm) |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

25 |

30 |

|

Theoretical Weight (kg/m) | ||||||||||||

|

10 |

0.238 |

0.32 |

0.4 |

0.48 |

0.63 |

|

|

|

|

|

|

|

|

15 |

0.36 |

0.48 |

0.59 |

0.71 |

0.95 |

1.19 |

|

|

|

|

|

|

|

20 |

0.476 |

0.63 |

0.79 |

0.95 |

1.27 |

1.59 |

1.9 |

|

|

|

|

|

|

25 |

0.585 |

0.79 |

0.99 |

1.19 |

1.59 |

1.98 |

2.38 |

|

|

|

|

|

|

30 |

0.714 |

0.95 |

1.19 |

1.43 |

1.9 |

2.38 |

2.85 |

3.33 |

3.81 |

4.75 |

5.948 |

|

|

40 |

0.952 |

1.27 |

1.59 |

1.9 |

2.54 |

3.17 |

3.81 |

4.44 |

5.08 |

6.34 |

7.93 |

9.52 |

|

50 |

1.19 |

1.59 |

1.98 |

2.38 |

3.17 |

3.97 |

4.76 |

5.55 |

6.34 |

7.93 |

9.91 |

11.9 |

|

60 |

1.428 |

1.9 |

2.38 |

2.85 |

3.81 |

4.76 |

5.71 |

6.66 |

7.61 |

9.52 |

11.9 |

14.27 |

|

70 |

|

2.22 |

2.78 |

3.33 |

4.44 |

5.55 |

6.66 |

7.77 |

8.88 |

11.1 |

13.88 |

16.65 |

|

80 |

|

|

3.17 |

3.81 |

5.08 |

6.34 |

7.61 |

8.88 |

10.15 |

12.69 |

15.86 |

19.03 |

|

90 |

|

|

3.57 |

4.28 |

5.71 |

7.14 |

8.56 |

9.99 |

11.42 |

14.27 |

17.84 |

21.41 |

|

100 |

|

|

3.97 |

4.76 |

6.34 |

7.93 |

9.52 |

11.1 |

12.69 |

15.86 |

19.82 |

23.79 |

|

110 |

|

|

|

5.23 |

6.98 |

8.72 |

10.47 |

12.21 |

13.96 |

17.45 |

21.81 |

26.17 |

|

120 |

|

|

|

5.71 |

7.61 |

9.52 |

11.42 |

13.32 |

15.23 |

19.03 |

23.79 |

28.55 |

|

130 |

|

|

|

6.19 |

8.25 |

10.31 |

12.37 |

14.43 |

16.49 |

20.62 |

25.77 |

30.93 |

|

140 |

|

|

|

6.66 |

8.88 |

11.1 |

13.32 |

15.54 |

17.76 |

22.2 |

27.76 |

33.31 |

|

150 |

|

|

|

7.14 |

9.52 |

11.9 |

14.27 |

16.65 |

19.03 |

23.79 |

29.74 |

35.69 |

|

160 |

|

|

|

7.61 |

|

12.69 |

15.23 |

17.76 |

20.3 |

25.38 |

31.72 |

38.06 |

|

170 |

|

|

|

|

|

13.48 |

16.18 |

18.87 |

21.57 |

26.96 |

33.7 |

40.44 |

|

180 |

|

|

|

|

|

14.27 |

17.13 |

19.98 |

22.84 |

28.55 |

35.69 |

42.82 |

- Q: Stainless steel heating oven tube after treatment is heating blue will not be red?

- Unless they are not stainless steel, or they control the temperature of the heating tube, the continuous heating will be red, after all, the material has not changed. If the outside of the heating tube is ceramic, it won't be red.

- Q: Can stainless steel pipes be used in the renewable energy industry?

- Certainly, stainless steel pipes can be utilized in the renewable energy sector with great effectiveness. Stainless steel is an incredibly versatile and durable material that presents numerous advantages for diverse applications within renewable energy systems. One of the primary advantages of employing stainless steel pipes lies in their exceptional resistance to corrosion. This attribute renders them highly suitable for deployment in environments where exposure to moisture, chemicals, and other corrosive elements is prevalent. For instance, solar power plants, geothermal energy systems, and offshore wind farms benefit immensely from the ability of stainless steel pipes to endure these harsh circumstances and maintain their structural integrity over extended periods. Consequently, the frequency of repairs and replacements is minimized. Another merit of stainless steel pipes is their excellent strength-to-weight ratio, facilitating the design of lightweight and efficient structures for renewable energy endeavors. These pipes can be utilized in constructing support frames, structures, and pipelines for wind turbines, solar thermal collectors, and biomass power plants, among other applications. Their strength and durability contribute to the overall reliability and longevity of renewable energy systems. Moreover, stainless steel pipes exhibit resistance to extreme temperatures, making them highly appropriate for deployment in high-temperature scenarios like concentrated solar power systems. These pipes can withstand the intense heat generated by solar receivers without suffering deformation or degradation, ensuring the efficient transfer of heat within the system. In addition to their mechanical properties, stainless steel pipes are also hygienic and environmentally friendly. They are easily cleaned and maintained, thereby reducing the risk of contamination and ensuring the purity of fluids utilized in renewable energy processes. Furthermore, stainless steel is a recyclable material, aligning perfectly with the sustainability principles of the renewable energy industry. In summary, stainless steel pipes offer a dependable, long-lasting, and cost-effective solution for a wide range of applications within the renewable energy sector. Their corrosion resistance, strength, temperature tolerance, and environmental benefits make them an exceptional choice for fluid transportation, structural support, and the ability to withstand the demanding conditions encountered in renewable energy systems.

- Q: What is the difference between seamless and HFW stainless steel pipes?

- The manufacturing process and the presence of a welded seam distinguish seamless stainless steel pipes from HFW (High Frequency Welded) stainless steel pipes. Seamless stainless steel pipes are created by piercing a solid billet or ingot and rolling it into a cylindrical shape. This method eliminates the need for welding, resulting in a pipe without any seams or joints. The absence of a welded seam enhances the overall strength and integrity of the pipe, making it ideal for high-pressure applications. On the contrary, HFW stainless steel pipes are produced using high-frequency electric resistance welding. This process involves passing a flat strip of stainless steel through a series of rollers and longitudinally welding it using a high-frequency current. The welded seam is then heat-treated to ensure the same corrosion resistance as the base material. HFW pipes are generally more cost-effective compared to seamless pipes, making them a popular choice for various applications. While both seamless and HFW stainless steel pipes offer excellent corrosion resistance and durability, seamless pipes are often preferred in critical applications where high strength and reliability are essential. The absence of a welded seam minimizes the risk of leakage and failure, making them suitable for industries such as oil and gas, petrochemical, and nuclear power. HFW stainless steel pipes, on the other hand, are more commonly used in less demanding applications like water supply, plumbing, and construction. They provide a cost-effective solution without compromising overall performance and corrosion resistance. In conclusion, the main difference between seamless and HFW stainless steel pipes lies in their manufacturing process and the presence of a welded seam. Seamless pipes are produced without welding, offering superior strength and reliability for critical applications. HFW pipes, on the other hand, are manufactured through high-frequency electric resistance welding and are more cost-effective, making them suitable for less demanding applications.

- Q: Stainless steel why rust?

- Stainless steel surface adhesion of organic juice (such as vegetables, soup, sputum), oxygen in the water under the circumstances, a long time, organic acid, organic acid on the surface of metal corrosion.

- Q: Can stainless steel water pipes be cooled and bent?

- They are lighter in bending and torsional strength, and therefore are widely used in the manufacture of mechanical parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: What is sanitary stainless steel pipe?

- Forbidden oil degree: after the passivation is finished, the cleaning of the forbidden oil is carried out, and the oil pollution on the surface of the steel pipe is removed. After the completion, the grease analyzer is used to check the oil pollution in the pipe wall, and the fluid substance that flows in the pipe is prevented

- Q: What is the difference between seamless and spiral welded stainless steel pipes?

- The main difference between seamless and spiral welded stainless steel pipes lies in their manufacturing process. Seamless pipes are formed by piercing a solid billet of stainless steel and then rolling it into a pipe shape, resulting in a continuous and uniform structure. On the other hand, spiral welded pipes are made by rolling a coil of stainless steel into a spiral shape and welding the edges together. This creates a noticeable weld seam along the length of the pipe. While seamless pipes are generally considered to have superior strength and aesthetic appeal due to their uninterrupted structure, spiral welded pipes are often more cost-effective and suitable for applications requiring larger diameters.

- Q: Are stainless steel pipes more expensive than other materials?

- Although stainless steel pipes tend to be more expensive compared to other materials, they offer significant advantages that justify their higher cost. Renowned for their exceptional durability, corrosion resistance, and longevity, stainless steel pipes can endure extreme temperatures, harsh chemicals, and high pressure, making them suitable for a wide range of applications like construction, plumbing, and industrial processes. Furthermore, stainless steel pipes necessitate minimal maintenance, providing long-term cost reductions. Despite the initial investment being higher, the superior performance and extended lifespan of stainless steel pipes render them a worthwhile choice in numerous scenarios. Ultimately, the decision to opt for stainless steel pipes should be based on the specific requirements and budget limitations of the project.

- Q: How do stainless steel pipes compare to copper pipes?

- Stainless steel pipes and copper pipes are both widely utilized in various applications, yet they possess distinct characteristics that differentiate them. The resistance to corrosion is one of the primary distinctions between stainless steel pipes and copper pipes. Stainless steel pipes exhibit exceptional corrosion resistance, rendering them suitable for environments with high humidity or chemical exposure. Conversely, copper pipes also possess corrosion resistance, albeit not to the same degree as stainless steel. They may gradually corrode when subjected to specific chemicals or acidic conditions. Cost is another aspect to consider. Copper pipes generally carry a higher price tag than stainless steel pipes. However, copper is an exceedingly efficient conductor of heat and electricity, making it a preferred option for heat transfer applications like plumbing and HVAC systems. Stainless steel pipes also exhibit good conductivity but are generally less expensive than copper pipes, making them a cost-effective alternative in many cases. Regarding durability, stainless steel pipes are renowned for their strength and ability to withstand high pressures, rendering them suitable for industrial applications and underground installations. Although copper pipes are also durable, they may be more susceptible to damage in extreme conditions or under excessive pressure. Ease of installation is another factor to take into account. Copper pipes are relatively easy to work with due to their malleability, enabling simple bending and shaping. Conversely, stainless steel pipes tend to be harder and necessitate specialized tools for cutting and bending. In conclusion, stainless steel pipes provide superior corrosion resistance, cost-effectiveness, and are ideal for high-pressure applications. On the other hand, copper pipes possess excellent heat transfer properties and are more malleable, making them suitable for plumbing and HVAC systems. Ultimately, the choice between stainless steel and copper pipes depends on the specific requirements of the application and budget constraints.

- Q: What is the difference between the stainless steel pipe welded pipe and seamless pipe?

- Seamless tube is a strip of steel with a hollow cross section and no seams at all. The general is rolled into a cylindrical tube plate welding.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords