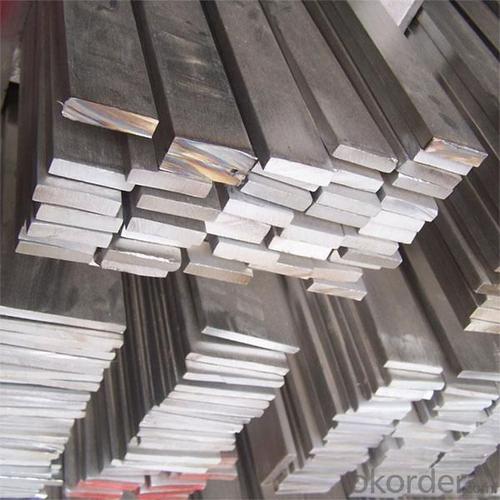

Stainless Steel Flats

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

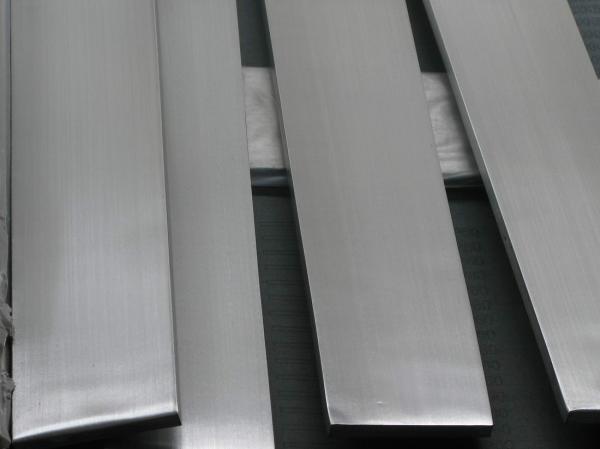

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: Can stainless steel pipes be buried in soil?

- Yes, stainless steel pipes can be buried in soil. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of being buried underground, making it a suitable choice for various underground applications such as drainage, sewage, and water supply systems.

- Q: What is stainless steel decorative tube? What uses does it have?

- Stainless steel decorative tubes, decorative stainless steel tubes, made of stainless steel anti-theft windows, stainless steel railings, stainless steel staircase handrails, interior modeling, etc.

- Q: Can stainless steel pipes be insulated with polyacrylonitrile?

- Indeed, polyacrylonitrile (PAN) can be employed to insulate stainless steel pipes. PAN, a highly adaptable and widely utilized polymer, boasts exceptional thermal insulation capabilities. Thanks to its low thermal conductivity and resistance to heat transfer, PAN is frequently utilized as a foam or fiber insulation material. Applying PAN insulation to stainless steel pipes is a straightforward process that aids in minimizing heat loss or gain, enhancing energy efficiency, and averting condensation. Furthermore, it affords protection against corrosion and mechanical harm.

- Q: Do stainless steel pipes require any special maintenance?

- Stainless steel pipes do not require any special maintenance as they are known for their durability and resistance to corrosion. However, regular cleaning and inspection are recommended to ensure optimal performance and longevity. This can be done by using mild soap and water or a non-abrasive cleaner to remove any dirt or grime that may accumulate on the surface. Additionally, inspecting the pipes for any signs of damage or leaks is important to address any issues promptly. Overall, stainless steel pipes are relatively low maintenance and can provide years of reliable service with proper care.

- Q: Stainless steel pipe is mainly used in what areas?

- According to the use of stainless steel pipe can be divided into oil well pipe (casing, tubing and drill pipe etc.), line pipe, boiler tube, mechanical structure, hydraulic prop pipe pipe, cylinder pipe, geological pipe, chemical pipe (high pressure fertilizer pipe, oil cracking tube) and shipbuilding pipe etc..

- Q: What is the difference between seamless and hot-expanded stainless steel pipes?

- Two distinct methods exist for manufacturing stainless steel pipes: seamless and hot expansion. Seamless stainless steel pipes are formed by piercing a solid billet of stainless steel and rolling it into the desired pipe shape. In this process, there is no welding or joining of separate pieces, resulting in a seamless pipe. These pipes are renowned for their uniformity and strength, as they lack weak points or potential leak paths. Although more expensive to produce, they are essential in applications requiring high corrosion resistance and pressure handling, such as in the oil and gas industry or high-pressure boilers. Conversely, hot-expanded stainless steel pipes are created by heating a stainless steel pipe and expanding it to a larger diameter using a mandrel within the pipe. This method is employed to produce larger diameter pipes for specific purposes. The hot expansion process can enhance the mechanical properties of the pipe, including increased tensile strength and improved corrosion resistance. Industries such as petrochemical, power generation, and construction frequently employ these pipes. In conclusion, the key distinction between seamless and hot-expanded stainless steel pipes lies in their manufacturing processes and resulting properties. Seamless pipes are crafted by rolling a solid billet, while hot-expanded pipes are formed by heating and expanding an existing pipe. Seamless pipes are recognized for their strength and uniformity, while hot-expanded pipes are often utilized for larger diameter applications and can possess enhanced mechanical properties.

- Q: What is the average weight of a stainless steel pipe?

- The average weight of a stainless steel pipe can vary depending on its diameter, thickness, and length.

- Q: Can stainless steel pipes be used in marine environments?

- Yes, stainless steel pipes can be used in marine environments. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for marine applications. It can withstand the harsh conditions of saltwater, such as high levels of humidity, moisture, and exposure to various chemicals. Stainless steel pipes are commonly used in marine vessels, offshore platforms, and other marine structures due to their durability and long-lasting performance. They provide excellent strength and reliability, even in challenging environments, making them a preferred choice for marine applications.

- Q: How can I clean the stainless steel tube?

- Can be soaked in soapy water and cleaned with a mild sponge pad. After washing, remember to rinse and dry the stainless steel.

- Q: Water and electricity thin wall stainless steel tube 304 material delta 2 what does that mean?

- 304 is a stainless steel number, 2.9 refers to the pipe wall thickness.

Send your message to us

Stainless Steel Flats

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords