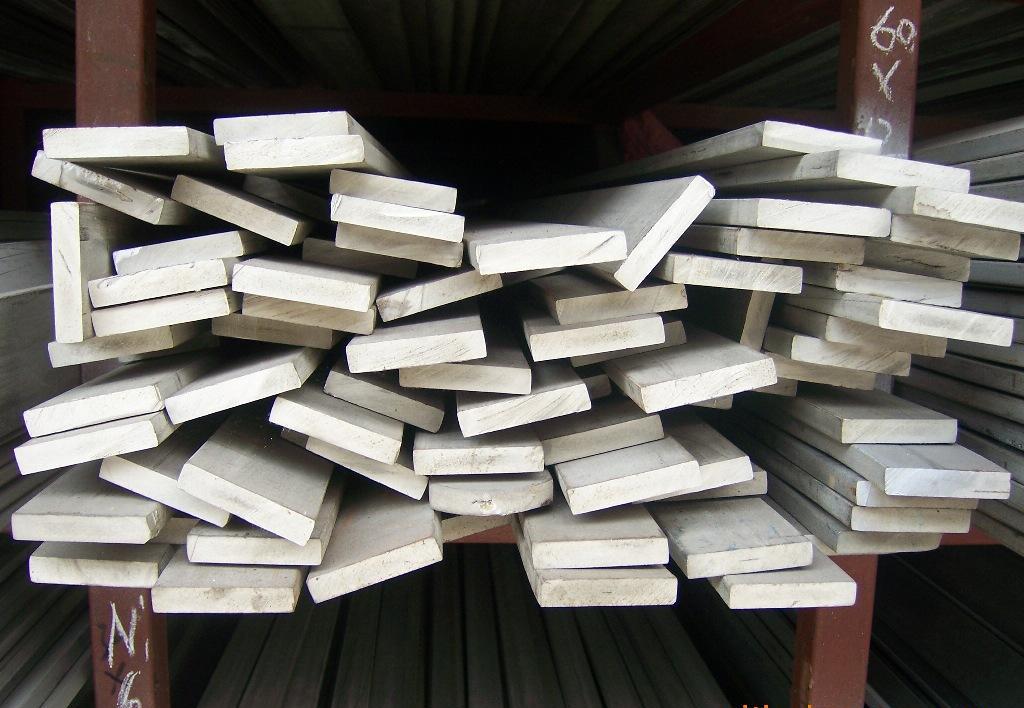

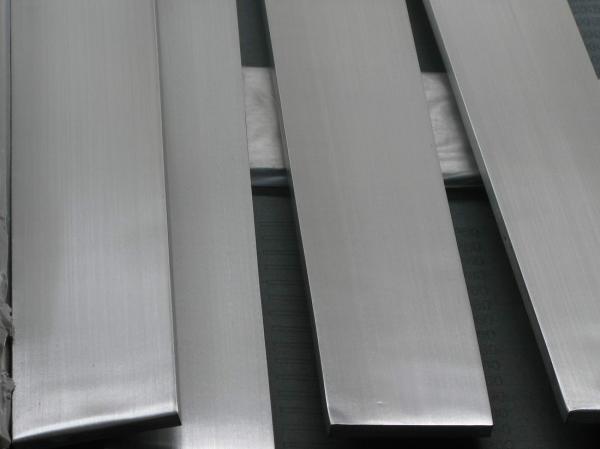

316L Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: Can stainless steel pipes be insulated with polycaprolactone?

- Stainless steel pipes can indeed be insulated with polycaprolactone. Polycaprolactone, also known as PCL, is a thermoplastic polymer that has excellent thermal insulation properties. It has a low thermal conductivity, which makes it an effective choice for insulating pipes and preventing heat loss or gain. Additionally, PCL is also resistant to moisture and chemicals, making it suitable for various environments and applications. When applied as insulation on stainless steel pipes, polycaprolactone can help maintain the desired temperature, reduce energy consumption, and prevent condensation.

- Q: How are stainless steel pipes manufactured?

- Stainless steel pipes are manufactured through a multi-step process that involves various stages of fabrication and shaping. The manufacturing process begins with the selection of high-quality stainless steel, usually in the form of sheets or coils. These steel sheets are thoroughly inspected for any defects or imperfections before being cut into the desired length or size. Once the sheets are cut, they are fed into a forming machine where they are rolled into the shape of a cylindrical tube. This process is known as cold rolling, and it helps to give the pipe its initial shape and thickness. The rolled sheets are then welded together using either a high-frequency induction welding technique or a submerged arc welding method. Both methods ensure a strong and durable weld joint. After the welding process, the pipe goes through a series of finishing treatments to improve its appearance and physical properties. The first step is to remove any excess weld material using a trimming machine. This ensures a smooth and even surface along the length of the pipe. Next, the pipe is subjected to a heat treatment called annealing. Annealing helps to relieve internal stresses and improve the pipe's mechanical properties. It also enhances the corrosion resistance of the stainless steel. Following annealing, the pipe may undergo additional processes such as pickling and passivation. Pickling involves immersing the pipe in an acid solution to remove surface impurities and oxides. Passivation, on the other hand, involves treating the pipe with a chemical solution to create a protective oxide layer on its surface, enhancing its resistance to corrosion. Once the finishing treatments are complete, the pipes are cut to the desired length and undergo a final inspection for quality assurance. This involves checking dimensions, surface finish, weld integrity, and overall appearance. In conclusion, stainless steel pipes are manufactured through a meticulous process that includes cutting, forming, welding, finishing treatments, and quality control measures. This ensures that the pipes meet the required standards and exhibit excellent properties such as strength, durability, and corrosion resistance.

- Q: What is the difference between seamless and high-frequency welded stainless steel pipes?

- Seamless and high-frequency welded stainless steel pipes are two different types of pipes used in various applications. Seamless stainless steel pipes are manufactured through a process called seamless pipe manufacturing, where a solid billet is heated and pierced to form a hollow tube. This process ensures that there are no seams or joints in the pipe, making it ideal for applications that require high pressure, high temperature, or corrosive environments. Seamless pipes offer superior strength and reliability due to their uniform composition and absence of welding. On the other hand, high-frequency welded stainless steel pipes are manufactured using a different process known as high-frequency welding. This process involves passing a flat strip of stainless steel through a series of rollers to form a tube shape. The edges of the strip are then heated using high-frequency electrical currents and fused together to create a solid pipe. The resulting pipe has a visible welded seam along its length. While both seamless and high-frequency welded stainless steel pipes are made from stainless steel, there are some differences between them. One major difference is the manufacturing process. Seamless pipes are made without any welding, resulting in a pipe with no seams or joints. High-frequency welded pipes, on the other hand, have a visible welded seam along their length. Another difference is in their strength and reliability. Seamless pipes have a more uniform composition and absence of welding, which gives them higher strength and reliability compared to high-frequency welded pipes. This makes seamless pipes more suitable for applications that require high pressure, high temperature, or corrosive environments. Additionally, the production cost of seamless pipes is generally higher than that of high-frequency welded pipes. The seamless pipe manufacturing process requires more complex machinery and additional steps, leading to higher production costs. High-frequency welded pipes, on the other hand, involve a simpler and more cost-effective manufacturing process. In summary, the main difference between seamless and high-frequency welded stainless steel pipes lies in their manufacturing process, strength, and cost. Seamless pipes are made without any welding, offering higher strength and reliability, but at a higher cost. High-frequency welded pipes have a visible welded seam but are more cost-effective. The choice between the two types of pipes depends on the specific requirements of the application and the budget available.

- Q: What are the different types of stainless steel pipe finishes?

- Stainless steel pipes come in various finishes, each offering a distinct look and level of protection against corrosion. 1. The mill finish is the standard and least flashy option for stainless steel pipes fresh from the mill. Its surface is dull and lacks reflectivity, making it suitable for applications where appearance is not a priority. 2. The brushed finish, also known as satin finish, involves brushing the surface of the stainless steel pipe with a fine abrasive material. This creates a consistent linear grain pattern, giving the pipe a smooth and sophisticated appearance. 3. The mirror finish is achieved by polishing the stainless steel pipe to a highly reflective surface. It is often used in decorative applications, such as handrails and architectural elements, where a shiny and visually pleasing look is desired. 4. The polished finish is similar to the mirror finish, but it does not achieve the same level of reflection. It involves buffing the surface of the stainless steel pipe to a high shine. This makes it more suitable for industrial or commercial applications. 5. The satin finish, a type of brushed finish, has a low sheen and smooth texture. It provides a subtle and elegant appearance, commonly used in applications where a matte finish is preferred, like kitchen appliances or automotive parts. 6. The bead blasted finish is accomplished by subjecting the surface of the stainless steel pipe to high-pressure bombardment with small glass beads. This creates a uniform and non-directional texture, giving the pipe a frosted and matte look. The bead blasted finish is often used in architectural and decorative applications. These different stainless steel pipe finishes offer their own advantages and are selected based on specific requirements, such as aesthetics, corrosion resistance, and ease of maintenance.

- Q: How do you determine the size of a stainless steel pipe?

- The size of a stainless steel pipe is determined by measuring its outer diameter using a caliper or a tape measure.

- Q: Can stainless steel pipes be used for construction?

- Certainly, construction can utilize stainless steel pipes. Stainless steel, being an incredibly durable and corrosion-resistant material, is well-suited for a wide range of construction applications. It is frequently employed in plumbing systems, water supply lines, and underground piping where the ability to resist corrosion is of utmost importance. Moreover, stainless steel pipes are utilized in the construction of bridges, buildings, and infrastructure projects due to their robustness and capacity to withstand harsh weather conditions. Furthermore, the aesthetic appeal and minimal upkeep requirements of stainless steel make it a preferred choice for architectural designs. In conclusion, stainless steel pipes are a dependable and enduring option for construction purposes.

- Q: How do stainless steel pipes compare to copper nickel pipes?

- Various industries commonly utilize stainless steel pipes and copper nickel pipes due to their unique properties and advantages. Although their purposes are similar, there are notable distinctions between the two. To begin, stainless steel pipes consist of an alloy primarily composed of iron, with substantial amounts of chromium and other elements. They exhibit exceptional resistance to corrosion, making them suitable for applications that prioritize durability and longevity. Additionally, stainless steel pipes possess considerable strength, rendering them ideal for high-pressure environments. Furthermore, they can withstand extreme temperatures, making them suitable for a wide array of applications. On the other hand, copper nickel pipes are comprised of an alloy that combines varying proportions of copper and nickel. These pipes possess high resistance to corrosion, particularly in seawater environments, which makes them highly useful in marine applications. Furthermore, copper nickel pipes exhibit excellent thermal conductivity and resist biofouling, making them suitable for heat exchangers and condensers in diverse industries. Regarding cost, stainless steel pipes generally offer a more affordable option compared to copper nickel pipes. The price difference can significantly impact decisions involving large-scale installations or projects with budget constraints. Furthermore, the selection between stainless steel and copper nickel pipes depends on specific requirements and conditions. For instance, if corrosion resistance is the primary concern, copper nickel pipes would be the preferred choice, especially in marine environments. Conversely, if strength, durability, and versatility are paramount, stainless steel pipes would be the superior option. In conclusion, stainless steel pipes and copper nickel pipes each possess distinct advantages and applications. Both materials are excellent choices for various industries, but the ultimate decision relies on factors such as corrosion resistance, strength, thermal conductivity, and budget considerations.

- Q: Can stainless steel pipes be insulated with polyethylene-terephthalate glycol?

- No, stainless steel pipes cannot be insulated with polyethylene-terephthalate glycol.

- Q: Can stainless steel pipes be embossed?

- Yes, stainless steel pipes can be embossed.

- Q: What is the lifespan of stainless steel pipes?

- The lifespan of stainless steel pipes can vary depending on various factors such as the grade of stainless steel used, the environment in which they are installed, and the maintenance and care they receive. However, in general, stainless steel pipes have a long lifespan compared to other materials commonly used for piping systems. Stainless steel pipes are known for their durability and corrosion-resistant properties. They are designed to withstand harsh conditions, high temperatures, and various corrosive substances, making them suitable for a wide range of applications. This inherent resistance to corrosion allows stainless steel pipes to have a longer lifespan than pipes made from materials like carbon steel or plastic. In ideal conditions and proper maintenance, stainless steel pipes can last for several decades or even longer. In some cases, stainless steel pipes have been known to last for over 100 years. However, it is important to note that the actual lifespan can vary depending on the specific application and the level of care provided. Regular inspection, maintenance, and cleaning can help extend the lifespan of stainless steel pipes. This includes removing any deposits or buildup that may occur over time, as well as addressing any signs of corrosion or damage promptly. Additionally, choosing the appropriate grade of stainless steel for the intended application can also contribute to a longer lifespan. Overall, stainless steel pipes are known for their durability and longevity. With proper care and maintenance, they can provide reliable and efficient performance for many years, making them a popular choice in various industries and applications.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

316L Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords