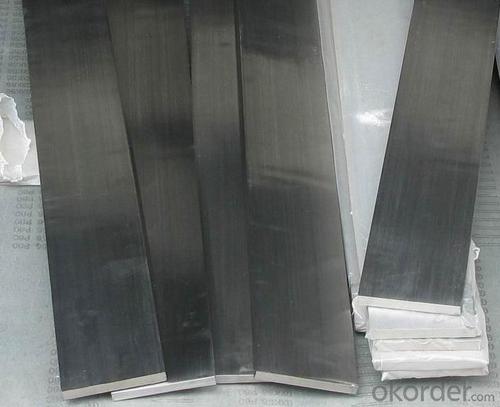

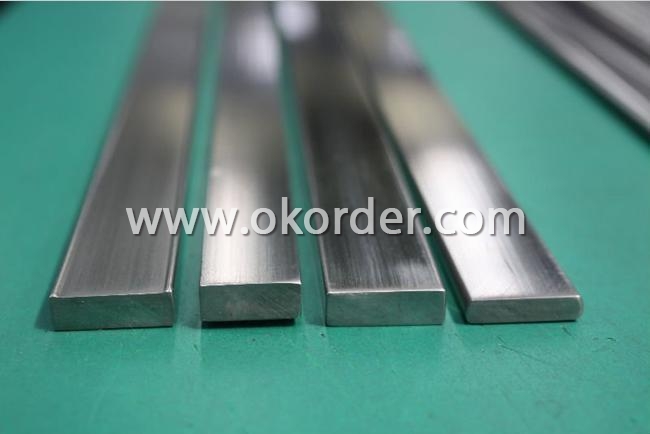

Stainless Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 2200MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flat Bar

Details of Stainless Steel Flat Bar:

Thickness: 3mm - 15mm

Width: 25mm - 120mm

Inch Thickness: 1/8" - 5/8"mm

Width: 1" - 4.1/2"mm

Standard: ASTM A276/484M ,EN 10058/DIN 1017

Advantages of Stainless Steel Flat Bar :

1* All products are made of high quality material

2* More than 300 patterns

3* Favouable price&Considerable service

4* Fast delivery

5* Quickest and most efficient response to your inquiry

Specifications of Stainless Steel Flat Bar :

1. Prime stainless steel bar

2. Raw materials from TG

3. Independent factory

4. Deliverd within 3-7 days

5. Best service

- Q: Can stainless steel pipes be used for swimming pool systems?

- Yes, stainless steel pipes can be used for swimming pool systems. Stainless steel is a popular choice for swimming pool piping due to its excellent corrosion resistance and durability. It is resistant to rust and can withstand exposure to chlorine, saltwater, and other chemicals commonly used in pool systems. Stainless steel pipes also have high strength, making them suitable for handling the pressure and flow of water in swimming pool systems. Additionally, stainless steel pipes are easy to clean and maintain, ensuring a long lifespan for the pool system.

- Q: What is the maximum pressure stainless steel pipes can handle?

- The maximum pressure that stainless steel pipes can handle depends on various factors such as the grade of stainless steel, the wall thickness of the pipe, and the specific application. Generally, stainless steel pipes have high resistance to pressure, making them suitable for various industrial applications. Stainless steel pipes are available in different grades, such as 304, 316, and 321, each with its own maximum pressure rating. For instance, grade 304 stainless steel pipes can typically handle pressures up to 870 psi (pounds per square inch), while grade 316 stainless steel pipes can handle pressures up to 1,500 psi. It is important to note that the wall thickness of the pipe also plays a significant role in determining its maximum pressure handling capacity. Thicker-walled pipes can generally handle higher pressures than thinner-walled pipes. Additionally, the specific application and the conditions under which the stainless steel pipes are used can impact their maximum pressure capacity. Factors like temperature, corrosive substances, and external forces should be considered to ensure the pipes can withstand the intended pressure. To determine the maximum pressure that stainless steel pipes can handle for a specific application, it is recommended to consult with a qualified engineer or refer to industry standards and guidelines, such as those provided by the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO). These resources provide detailed information on pressure ratings and specifications for different grades and sizes of stainless steel pipes.

- Q: Can stainless steel pipes be used for pharmaceutical processing equipment?

- Yes, stainless steel pipes can be used for pharmaceutical processing equipment. Stainless steel is a preferred material in the pharmaceutical industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is resistant to chemicals, corrosion, and high temperatures, making it suitable for handling and transporting various pharmaceutical substances. Additionally, stainless steel pipes have a smooth surface that minimizes the risk of contamination and allows for easy cleaning and sterilization. Overall, stainless steel pipes are widely used in pharmaceutical processing equipment to ensure the integrity and quality of pharmaceutical products.

- Q: About stainless steel welding deformation

- For welding of grade 304 stainless steel, the current can be adjusted a little, not preheating, to prevent deformation after welding, the welding sequence should pay attention to, such as left -- right -- in the welding line, avoid welding head, to prevent warping.

- Q: Are stainless steel pipes fire-resistant?

- Yes, stainless steel pipes are fire-resistant. Stainless steel is known for its high melting point and excellent resistance to fire. It does not readily ignite or contribute to the spread of fire, making it a safe material for various applications, including pipes. Stainless steel pipes can withstand high temperatures without significant deformation or structural damage, providing an added level of safety in fire-prone environments.

- Q: Are stainless steel pipes suitable for petrochemical plants?

- Yes, stainless steel pipes are highly suitable for use in petrochemical plants. Petrochemical plants handle highly corrosive substances, extreme temperatures, and high pressure conditions, making it essential to use materials that can withstand such harsh environments. Stainless steel pipes offer excellent corrosion resistance, ensuring they can withstand the corrosive nature of petrochemicals without deteriorating or compromising the integrity of the pipes. Additionally, stainless steel has high temperature resistance, making it suitable for the extreme heat encountered in petrochemical processes. Stainless steel pipes also have excellent mechanical properties, providing strength and durability required for high-pressure applications in petrochemical plants. Moreover, stainless steel is a hygienic material that does not contaminate the substances being transported, making it ideal for maintaining the purity of petrochemicals. Overall, stainless steel pipes are a reliable and preferred choice for petrochemical plants due to their corrosion resistance, temperature resistance, mechanical properties, and hygienic nature.

- Q: How do stainless steel pipes compare to HDPE pipes?

- When comparing stainless steel pipes to HDPE pipes, there are several factors to consider. Firstly, in terms of durability and strength, stainless steel pipes have a clear advantage. Stainless steel is known for its high tensile strength and resistance to corrosion, making it suitable for a wide range of applications. On the other hand, while HDPE pipes are also durable, they may not be as strong as stainless steel and may require additional support in certain situations. Secondly, when it comes to temperature resistance, stainless steel pipes again have an edge. They can withstand high temperatures without losing their structural integrity, making them suitable for applications involving hot fluids or gases. HDPE pipes, on the other hand, may soften or deform at elevated temperatures, limiting their use in high-temperature environments. Another aspect to consider is the ease of installation. HDPE pipes are typically lighter and more flexible than stainless steel pipes, making them easier to transport and install. They also require fewer fittings and joints, reducing the chances of leaks. However, stainless steel pipes can be more rigid and may require additional welding or threading during installation. Cost is another factor to consider. HDPE pipes are generally more cost-effective than stainless steel pipes, especially for larger diameter pipes. This affordability, coupled with the ease of installation, makes HDPE pipes a popular choice in many applications. However, it is important to note that stainless steel pipes have a longer lifespan and require less maintenance, potentially offsetting the initial cost difference over time. Ultimately, the choice between stainless steel pipes and HDPE pipes depends on the specific requirements of the application. While stainless steel pipes offer superior strength, temperature resistance, and longevity, HDPE pipes are lighter, more flexible, and more cost-effective. Assessing the needs of the project and considering these factors will help determine the most suitable option.

- Q: How do stainless steel pipes compare to PVC-U pipes?

- Various piping applications commonly utilize stainless steel pipes and PVC-U pipes, each possessing distinct characteristics and advantages. Primarily, stainless steel pipes are renowned for their remarkable strength and durability. With high resistance to corrosion, rust, and chemical reactions, they excel in applications where contact with aggressive substances or exposure to harsh environments is prevalent. Additionally, they can endure elevated temperatures and pressures, making them well-suited for demanding industrial uses. Conversely, PVC-U pipes, also known as polyvinyl chloride unplasticized pipes, offer lightweight properties and effortless installation. They provide cost-effective solutions and exhibit commendable chemical resistance, particularly against acids, alkalis, and salts. Plumbing, irrigation, and drainage systems commonly employ PVC-U pipes due to their superior flow characteristics and minimal maintenance requirements. Regarding versatility, stainless steel pipes cater to a broad spectrum of applications, including water supply, gas distribution, oil and gas pipelines, and sewage systems. They are frequently favored in industrial environments where reliability and longevity are paramount. Alternatively, PVC-U pipes find more widespread use in residential and commercial settings, prioritizing cost-efficiency and ease of installation. Notably, stainless steel pipes typically entail greater expense than PVC-U pipes, encompassing material costs and installation fees. Nonetheless, their extended lifespan and enhanced resistance to corrosion and chemical reactions often render them a more cost-effective option in the long term. Ultimately, the selection between stainless steel pipes and PVC-U pipes hinges on the specific requirements of the given application. Factors such as cost, durability, corrosion resistance, installation ease, and maintenance should all be contemplated when comparing these materials for a particular piping project.

- Q: Can stainless steel pipes be embossed?

- Certainly, it is possible to emboss stainless steel pipes. Embossing refers to the technique of raising or pressing a pattern or design into a material like stainless steel, with the intention of creating a decorative or functional effect. This technique can be applied to a wide range of metal surfaces, including stainless steel pipes. To achieve this, specialized machinery and tools are employed to imprint the desired design onto the pipe's surface. The purpose of embossing can be twofold: it may enhance the visual appeal and texture for aesthetic reasons, or provide functional benefits like improved grip and slip prevention. In summary, embossing stainless steel pipes is indeed viable and can yield diverse desired outcomes.

- Q: What is the difference between seamless and longitudinal welded stainless steel pipes?

- The manufacturing processes and structural characteristics of seamless and longitudinal welded stainless steel pipes vary. Seamless pipes, for instance, are formed by heating a solid cylindrical bar of stainless steel and pushing it through a die to create a hollow tube. This process eliminates the need for welded seams, resulting in a uniform composition and consistent strength and corrosion resistance. As a result, seamless pipes are commonly used in high-pressure applications like oil and gas pipelines and refinery equipment due to their superior mechanical properties. In contrast, longitudinal welded pipes are made by joining two separate pieces of stainless steel plate or sheet together through a longitudinal welding process. The plates or sheets are rolled into a cylindrical shape, and the seam is welded along the length of the pipe. This welding technique provides structural integrity and strength to the pipe, although it may introduce some slight inconsistencies in the steel's composition and properties. However, these inconsistencies can be minimized through appropriate welding techniques and quality control measures. Longitudinal welded pipes are widely used in various fields, including structural and architectural projects, as well as in industries such as food processing, pharmaceuticals, and petrochemicals. In conclusion, the main distinction between seamless and longitudinal welded stainless steel pipes lies in their manufacturing methods and resulting structural characteristics. Seamless pipes have no welded seams and offer excellent mechanical properties, making them suitable for high-pressure applications. On the other hand, longitudinal welded pipes are created by welding two separate stainless steel pieces together and are commonly utilized in different industries. The choice between these types of pipes depends on specific requirements and considerations for the intended application.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 2200MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords