Best Quality for Stainless Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2MT m.t.

- Supply Capability:

- 5000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

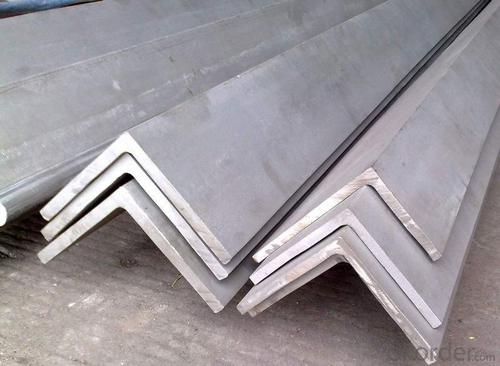

Details of Stainless Steel Angle:

Size mm | |

Width | Thickness |

25 x 25 | 3 4 5 |

30 x 30 | 3 4 5 |

40 x 40 | 3 4 5 6 |

50 x 50 | 4 5 6 |

60 x 60 | 5 6 7 |

65 x 65 | 5 6 7 |

70 x 70 | 6 7 8 |

75 x 75 | 6 7 8 9 |

80 x 80 | 7 8 9 10 |

100 x 100 | 8 9 10 12 |

Tolerance:GB4227, ASTM A276/A 484M, EN10056/DIN 1028 | |

Features of Stainless Steel Angle:

1. All products are made of high-quality imported raw materials.

2. Our products are certified by ISO9001:2008 authentication quality systems.

3. We are nominated as the AAA enterprise by Jiangsu government.

4. Quickest and most efficient Response to Your Enquiry.

5.Selected quality material

6.Finely processed

7.Prime quality&Bottom price

8.Complete in specifications

9.Abundant stock

Application of Stainless Steel Angle

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic --- cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Architectural/Civil Engineering---- cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports

3.Transport --- exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

4.Chemical/Pharmaceutical --- pressure vessels, process piping.

5.Oil and Gas ---platform accommodation, cable trays, subsea pipelines.

6.Medical ---Surgical instruments, surgical implants, MRI scanners.

7.Food and Drink ---Catering equipment, brewing, distilling, food processing.

8.Water ---Water and sewage treatment, water tubing, hot water tanks.

9.General ----springs, fasteners (bolts, nuts and washers), wire.

- Q: How do stainless steel angles contribute to the overall sustainability of a structure?

- Stainless steel angles play a significant role in enhancing the sustainability of a structure in multiple ways. Firstly, the exceptional durability and longevity of stainless steel are well-known. This material exhibits high resistance to corrosion, enabling it to withstand harsh environmental conditions and minimizing the need for frequent replacements or repairs. As a result, the overall environmental impact associated with the production, transportation, and disposal of construction materials is reduced. Moreover, stainless steel angles are entirely recyclable, making them an eco-friendly choice for construction projects. When their lifespan ends, these angles can be easily recycled without compromising their properties or quality. This approach reduces the demand for new raw materials and minimizes waste generation within the construction industry. Additionally, stainless steel is an environmentally conscious material as it does not release any harmful chemicals or gases during its production or use. It is free from toxic substances like lead, mercury, or cadmium, ensuring the safety of both human health and the environment. This aspect is particularly crucial in sustainable construction practices, where the emphasis lies in minimizing the ecological footprint of buildings. Furthermore, stainless steel angles possess excellent fire resistance properties, thereby enhancing the safety and sustainability of a structure. They do not burn or emit toxic gases when exposed to fire, thereby reducing the risk of flame spread and limiting potential damage to the building and its occupants. Lastly, stainless steel angles require minimal maintenance, further contributing to the sustainability of a structure. Given their resistance to corrosion, staining, and weathering, stainless steel angles do not necessitate frequent cleaning or surface treatments. Consequently, the consumption of water, energy, and chemical cleaning products is reduced. In conclusion, the incorporation of stainless steel angles into construction projects promotes overall sustainability by providing durability, recyclability, low environmental impact, fire resistance, and low maintenance requirements. By utilizing stainless steel angles, we can construct sustainable buildings that are long-lasting, safe, and environmentally friendly.

- Q: What are the surface treatment options for stainless steel angles?

- To achieve the desired aesthetics and functional requirements, there are several surface treatment options available for stainless steel angles. Passivation is a process that eliminates iron contamination and forms a protective oxide layer, improving corrosion resistance. Electropolishing, on the other hand, involves an electrochemical process that removes a thin layer of material, resulting in a smooth and shiny surface. This process enhances corrosion resistance and makes cleaning easier. For a brushed finish, brushing is used, wherein abrasive materials or brushes create parallel lines on the surface. This not only provides a decorative appearance but also hides minor imperfections. Bead blasting, a technique that propels fine glass beads or abrasive material at high speeds onto the stainless steel surface, offers a uniform matte finish. It removes surface contaminants and provides a smooth texture. To enhance the aesthetics and provide additional corrosion resistance, Physical Vapor Deposition (PVD) coating can be used. This thin film coating process offers various colors and finishes. Another option is powder coating, a dry finishing process where a free-flowing, electrostatically charged powder is applied to the surface. Once cured, it creates a durable, smooth, and decorative coating. For a highly reflective and mirror-like finish, mirror polishing is employed. This process involves grinding and buffing the stainless steel surface, commonly used in architectural and decorative applications. When choosing the appropriate surface treatment option, it is crucial to consider the specific requirements, environment, and intended use of the stainless steel angles.

- Q: How do stainless steel angles contribute to load distribution?

- Stainless steel angles contribute to load distribution by providing structural support and stability to various applications. The angled shape of these stainless steel components allows them to bear and distribute the weight of a load evenly, reducing the stress on other supporting elements. This helps in preventing any localized stress concentration and ensures a more balanced distribution of forces, ultimately enhancing the overall load-bearing capacity and structural integrity of the system.

- Q: What is the yield strength of stainless steel angles?

- The specific grade of stainless steel being used can cause variations in the yield strength of stainless steel angles. Typically, the yield strength of stainless steel angles falls within the range of 30,000 to 80,000 pounds per square inch (PSI). Nevertheless, it is crucial to acknowledge that this range can be influenced by factors such as the specific grade, thickness, and manufacturing process of the stainless steel angle. For precise information regarding the yield strength of a particular stainless steel angle, it is advisable to refer to the manufacturer's specifications or consult a materials engineer.

- Q: What is the difference between 316L and 316H stainless steel angles?

- The main difference between 316L and 316H stainless steel angles is their carbon content and resulting mechanical properties. 316L stainless steel angle has a lower carbon content, making it more resistant to corrosion and suitable for applications where welding is required. On the other hand, 316H stainless steel angle has a higher carbon content, providing increased strength and hardness, making it ideal for high-temperature and high-stress environments.

- Q: Can stainless steel angles be used in high-temperature environments?

- Indeed, high-temperature environments can accommodate the use of stainless steel angles. The remarkable corrosion resistance and impressive heat resistance of stainless steel are well-known. Its capacity to endure high temperatures without distorting or compromising its structural integrity is owed to its elevated melting point. Furthermore, stainless steel angles are commonly crafted from austenitic stainless steel, which boasts superior resistance to high temperatures when compared to other stainless steel grades. This renders stainless steel angles a fitting selection for various industries, including chemical processing, petrochemical, power generation, and furnace manufacturing, where high temperatures prevail.

- Q: Can stainless steel angles be used in military equipment manufacturing?

- Certainly, military equipment manufacturing can utilize stainless steel angles. Stainless steel is commonly selected due to its robustness, endurance, and ability to resist corrosion, all of which hold significant significance in military contexts. Stainless steel angles find utility in reinforcing structures, constructing support frames, and ensuring structural integrity in diverse military equipment like vehicles, weapons, and aircraft. Furthermore, stainless steel's capability to endure extreme temperatures and hostile environments renders it a fitting material for military equipment that might encounter demanding conditions.

- Q: What are the surface finish options for stainless steel angles?

- The surface finish options for stainless steel angles include a variety of options such as mill finish, brushed finish, mirror finish, satin finish, and bead blasted finish.

- Q: What are the different types of machining processes used with stainless steel angles?

- Stainless steel angles can undergo various machining processes to achieve different results. Some commonly used ones are: 1. Cutting: Material is removed from the stainless steel angle to achieve the desired shape or size. This can be done using tools like saws, shears, or plasma cutters. 2. Drilling: Holes are created in the stainless steel angle using drill bits designed for stainless steel or precision drilling using a CNC machine. 3. Grinding: The surface of the stainless steel angle is smoothed or any burrs or sharp edges are removed using abrasive wheels or belts that rotate against the angle. 4. Milling: Material is removed from the stainless steel angle using rotary cutters to create complex shapes or achieve a specific surface finish. 5. Welding: Two or more stainless steel angles are joined together by melting the edges and allowing them to fuse. This is commonly used in fabrication processes for larger structures or assemblies. 6. Bending: The stainless steel angle is deformed to a specific angle or shape using tools like press brakes or by heating the metal and manually bending it. Each of these machining processes has its own advantages and limitations. The choice of which process to use depends on factors such as the desired outcome, project complexity, and available equipment and resources.

- Q: Can stainless steel angles be used in wastewater treatment plants?

- Yes, stainless steel angles can be used in wastewater treatment plants. Stainless steel is highly resistant to corrosion and can withstand the harsh and corrosive environment typically found in wastewater treatment plants. The angles are commonly used for structural support, as well as for the construction of tanks, pipes, and other equipment in these facilities. Stainless steel angles offer excellent strength and durability, making them suitable for heavy-duty applications in wastewater treatment plants. Additionally, stainless steel is also known for its hygienic properties, which is crucial in maintaining proper sanitation and preventing the growth of bacteria or other contaminants in these environments.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Stainless Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2MT m.t.

- Supply Capability:

- 5000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords