304/316 stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:21.3*3.73mm or others

2.Surface:4k/6k//8k

3.Length:6m or as your requirement

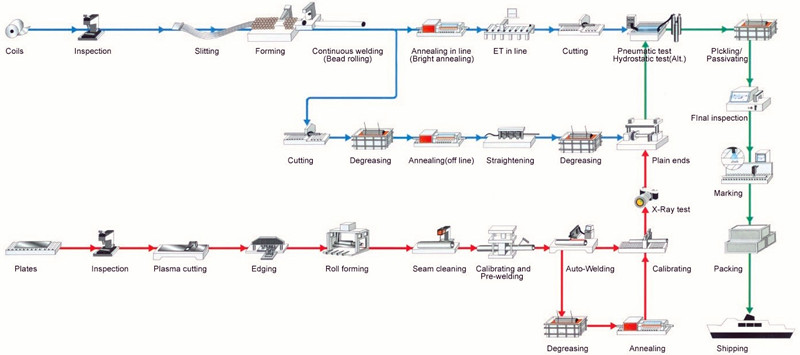

A series of photos

A series of pictures

- Q: What are the different types of stainless steel pipe bends?

- There are several different types of stainless steel pipe bends available in the market. Some of the most commonly used types include: 1. Long radius bends: These bends have a larger radius compared to other types, which results in a smoother flow of fluid or gas through the pipe. They are often used in applications where the flow needs to be maintained at a consistent speed or where there are concerns about pressure drop. 2. Short radius bends: These bends have a smaller radius, which means they have a tighter curvature compared to long radius bends. They are typically used in applications where space is limited, such as in tight corners or in compact piping systems. 3. U-bends: U-bends have a 180-degree curve, forming a U-shape. They are commonly used in heat exchanger systems, where they allow for the efficient transfer of heat between two fluids. 4. 3D bends: 3D bends have a radius three times the diameter of the pipe. They are often used in applications where there is a need for a gradual change in direction, as they provide a smoother flow compared to sharper bends. 5. 5D bends: 5D bends have a radius five times the diameter of the pipe. They are typically used in applications where there are strict requirements for fluid or gas flow, as they minimize pressure drop and turbulence. 6. Mandrel bends: Mandrel bends are formed using a mandrel, which is a solid rod inserted into the pipe during the bending process. This helps maintain the shape and integrity of the pipe, resulting in a smooth and uniform bend. Mandrel bends are often used in applications where there are strict requirements for the roundness and smoothness of the bend. It is important to choose the right type of stainless steel pipe bend based on the specific requirements of the application, such as the fluid or gas being transported, the pressure and temperature conditions, as well as any space limitations. Consulting with a professional or supplier can help ensure the appropriate selection of pipe bends for the specific application.

- Q: How can the inner walls of stainless steel tubes be polished?

- After polishing, because the surface oxide layer received damage, it is best to use acid solution surface passivation treatment, otherwise it is easy to rust.

- Q: How do you calculate the pressure drop in stainless steel pipes?

- To calculate the pressure drop in stainless steel pipes, you can use various methods such as the Darcy-Weisbach equation, the Hazen-Williams equation, or the Manning formula. These formulas consider factors like pipe diameter, length, flow rate, fluid properties, and pipe roughness to determine the pressure loss. Additionally, online calculators and software programs are available to simplify the calculations.

- Q: Can stainless steel pipes be used for water treatment facilities?

- Stainless steel pipes are suitable for water treatment facilities. The reason behind this preference is the excellent corrosion resistance properties of stainless steel. Since water treatment facilities handle various chemicals and substances that can cause corrosion in pipes, stainless steel is the ideal material choice. It provides a long-lasting and durable solution for transporting water and other fluids. Moreover, stainless steel pipes have a smooth surface finish, preventing the growth of biofilms and reducing the risk of contamination during water treatment processes. This is crucial for maintaining the quality and safety of the treated water. Another benefit of using stainless steel pipes in water treatment facilities is their ability to withstand high temperatures and pressures. They can handle the demanding operational conditions typically encountered in water treatment processes. Furthermore, stainless steel pipes are hygienic and easy to clean, making them perfect for use in water treatment facilities where cleanliness and sanitation are of utmost importance. In summary, stainless steel pipes are a reliable, corrosion-resistant, hygienic, and durable solution for water treatment facilities. They are well-suited for transporting water and other fluids in such settings.

- Q: How much is one ton of stainless steel pipe?

- If you want to use industrial, production, 316L is the best, but the price is expensive, but the best rust resistance, high stability.

- Q: Are stainless steel pipes suitable for marine applications?

- Stainless steel pipes are perfectly suited for marine applications due to their exceptional corrosion resistance. The stainless steel material is renowned for its ability to withstand harsh conditions in marine environments, including saltwater exposure. This is primarily attributed to the high levels of chromium present in stainless steel, which create a protective oxide layer on the surface. Consequently, the pipes are shielded from corrosion and rusting, ensuring their longevity and integrity. Besides, stainless steel pipes possess favorable mechanical properties and can endure high temperatures, making them highly suitable for a range of marine uses, such as offshore platforms, shipbuilding, and underwater pipelines. Given their remarkable durability, long lifespan, and resistance to corrosion, stainless steel pipes are an extremely reliable option for marine applications.

- Q: Are stainless steel pipes resistant to scaling and oxidation?

- Stainless steel pipes possess exceptional resistance against scaling and oxidation due to the presence of a protective chromium oxide layer on their surface. This layer acts as a barrier, shielding the underlying metal from oxygen and other elements that can lead to scaling and oxidation. Consequently, stainless steel pipes are capable of enduring high temperatures, corrosive surroundings, and frequent contact with water without any deterioration or rusting. Hence, they are an ideal option for numerous applications in industries like construction, chemical, and food processing, where the ability to resist scaling and oxidation is paramount.

- Q: How do you prevent stress corrosion cracking in stainless steel pipes?

- To prevent stress corrosion cracking in stainless steel pipes, several precautions can be taken: 1. Material selection: Choose a stainless steel grade that is resistant to stress corrosion cracking. Austenitic stainless steel grades such as 304 and 316 are commonly used due to their high resistance to corrosion and cracking. 2. Proper fabrication and welding: Ensure that the welding procedures used during fabrication are suitable for stainless steel and minimize the introduction of residual stresses. This includes using proper welding techniques, maintaining appropriate heat input, and employing post-weld heat treatment if necessary. 3. Avoid exposure to corrosive environments: Protect stainless steel pipes from exposure to aggressive chemicals, high chloride concentrations, and other corrosive substances. Regularly inspect the environment and take necessary measures to prevent contact between the pipes and corrosive agents. 4. Control operating conditions: Avoid subjecting stainless steel pipes to excessive tensile stresses or temperatures that can promote stress corrosion cracking. This can be achieved by maintaining proper operating conditions, such as controlling pressure, temperature, and flow rates within the recommended limits. 5. Regular inspection and maintenance: Conduct regular inspections to identify any signs of stress corrosion cracking. This may include visual inspections, non-destructive testing techniques (e.g., ultrasonic testing), or corrosion monitoring. If any signs of stress corrosion cracking are detected, immediate action should be taken to repair or replace the affected pipe sections. 6. Proper cleaning and maintenance: Keep stainless steel pipes clean and free from contaminants that can accelerate corrosion. Regular cleaning and maintenance practices should be followed, including removing any deposits or foreign materials that may promote stress corrosion cracking. Overall, preventing stress corrosion cracking in stainless steel pipes requires a combination of proper material selection, fabrication techniques, environmental control, regular inspections, and appropriate maintenance practices. By implementing these measures, the risk of stress corrosion cracking can be significantly reduced, ensuring the longevity and reliability of stainless steel pipes.

- Q: Can stainless steel pipes be cold worked?

- Yes, stainless steel pipes can be cold worked. Cold working is a process in which the metal is deformed at room temperature, typically through processes like bending, drawing, or rolling. Stainless steel's excellent mechanical properties and ductility make it well-suited for cold working, allowing for the creation of complex shapes and designs while retaining its strength and corrosion resistance.

- Q: What is the internal roughness of stainless steel pipes?

- The internal roughness of stainless steel pipes refers to the texture or unevenness on the inner surface of the pipes, which can affect the flow of fluids or gases through the pipes. It is typically measured in terms of roughness coefficients or Ra values, indicating the average height of irregularities on the pipe's interior.

Send your message to us

304/316 stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords