304/316 seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:88.9*5.49 mm or others

2.Surface: NO.1

3.Length:6m or as your requirement

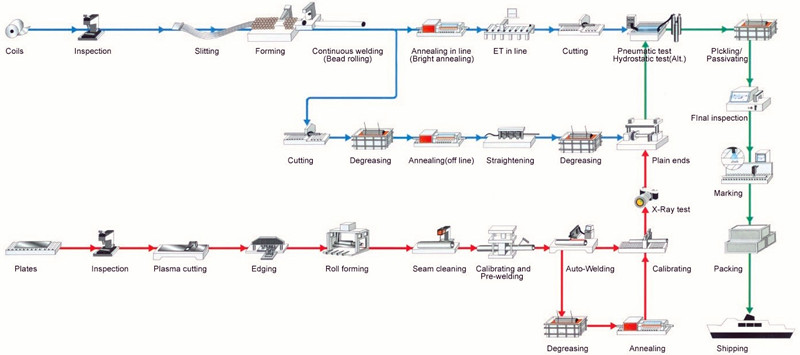

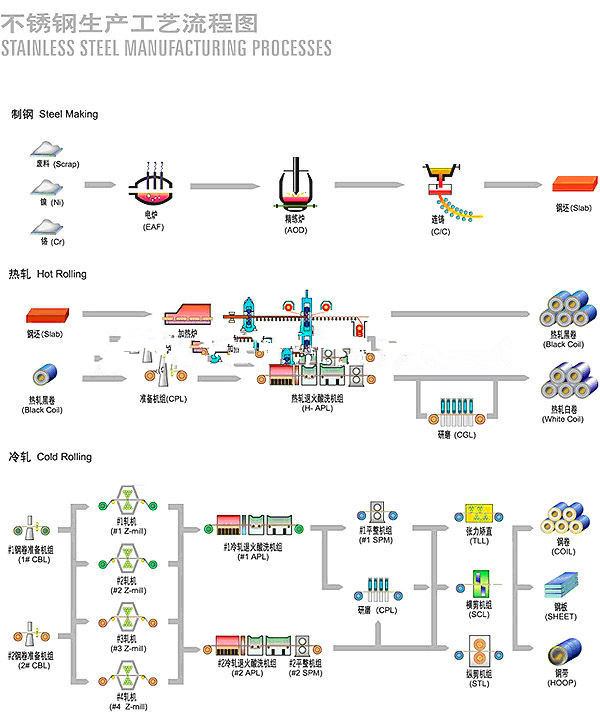

A series of photos

A series of pictures

- Q: Can stainless steel pipes be insulated for soundproofing?

- Yes, stainless steel pipes can be insulated for soundproofing. Insulation materials such as rubber or foam can be wrapped around the pipes to reduce noise transmission. The insulation helps to absorb or dampen the sound waves traveling through the pipes, thus minimizing the noise produced.

- Q: How do you calculate the bending radius of stainless steel pipes?

- The bending radius of stainless steel pipes can be calculated using a formula that takes into account the outside diameter (OD) of the pipe, the wall thickness (WT), and the material's elongation factor. The formula is: Bending radius = (OD - WT) x Elongation factor.

- Q: Can stainless steel pipes be used for sewage treatment plants?

- Yes, stainless steel pipes can be used for sewage treatment plants. Stainless steel offers exceptional resistance to corrosion, making it an ideal choice for handling wastewater and other corrosive substances commonly found in sewage treatment plants. Additionally, stainless steel pipes are durable, hygienic, and easy to maintain, making them suitable for the demanding conditions of sewage treatment facilities.

- Q: What is the difference between 304H and 304 stainless steel pipes?

- The carbon content is what sets 304H stainless steel pipes apart from 304. Although both grades belong to the 304 stainless steel alloy, 304H has a higher carbon content than 304. This increased carbon content gives 304H pipes the ability to withstand higher temperatures, as they possess better strength and resistance against sensitization. Conversely, 304 stainless steel pipes are better suited for general applications due to their good corrosion resistance and widespread use in various industries. Consequently, when deciding between 304H and 304 stainless steel pipes, it is important to consider the specific requirements of the application, including the operating temperature and the need for enhanced strength and resistance against sensitization.

- Q: What is the welding procedure for stainless steel pipes?

- The welding procedure for stainless steel pipes involves cleaning the surfaces to be welded, preheating the pipes to the recommended temperature, selecting the appropriate welding method (TIG, MIG, or stick), and using the correct filler material. The welder should maintain proper shielding gas flow, control the heat input, and ensure consistent and smooth welding passes. Post-welding, the weld area should be properly cleaned and inspected for any defects.

- Q: What are the common applications of stainless steel pipes in the construction industry?

- Stainless steel pipes are commonly used in the construction industry for various applications such as water and gas supply systems, heating and ventilation systems, structural supports, and exterior cladding. They are preferred for their corrosion resistance, durability, and strength, making them suitable for both indoor and outdoor construction projects.

- Q: Can stainless steel pipes be used for pharmaceutical manufacturing?

- Yes, stainless steel pipes can be used for pharmaceutical manufacturing. Stainless steel has several properties that make it suitable for this industry. Firstly, stainless steel is corrosion-resistant, which is crucial for maintaining the purity of pharmaceutical products. It can resist the attack of chemicals and withstand harsh cleaning processes without deteriorating or contaminating the pharmaceuticals. Secondly, stainless steel is easy to clean and sanitize, which is essential in maintaining a high level of hygiene during pharmaceutical manufacturing. The smooth surface of stainless steel pipes prevents the accumulation of bacteria and other contaminants. Additionally, stainless steel is a durable material that can withstand high temperatures and pressures, making it suitable for various pharmaceutical processes such as sterilization and purification. Overall, stainless steel pipes are a reliable and commonly used choice for pharmaceutical manufacturing due to their corrosion resistance, easy cleanability, and durability.

- Q: Are stainless steel pipes resistant to chemicals?

- Yes, stainless steel pipes are generally resistant to chemicals. Stainless steel is known for its corrosion resistance properties, which makes it an ideal material for various applications, including pipes that are exposed to different chemicals. The high levels of chromium in stainless steel create a protective layer on the surface of the material, preventing it from reacting with most chemicals and corrosive substances. However, it is important to note that the resistance of stainless steel pipes to chemicals can vary depending on the specific type and grade of stainless steel used. In some cases, certain aggressive chemicals or extreme conditions may still cause corrosion or damage to stainless steel pipes, so it is always advisable to consult with experts or refer to specific chemical resistance charts for accurate information on the compatibility of stainless steel pipes with different chemicals.

- Q: Can stainless steel pipes be used for underground gas lines?

- Yes, stainless steel pipes can be used for underground gas lines. Stainless steel is known for its excellent corrosion resistance, which makes it a suitable choice for underground applications where the pipes are exposed to moisture and various chemicals present in the soil. Stainless steel pipes also have a high strength-to-weight ratio, making them durable and able to withstand the pressure and environmental conditions associated with underground gas lines. Additionally, stainless steel pipes have a long lifespan and require minimal maintenance, making them a cost-effective and reliable option for underground gas distribution systems.

- Q: How can I clean the stainless steel tube?

- 1, cleaning stainless steel gently method is simply to use hot water and clean soft cloth to wipe the surface, and then use dry metal with other soft cloth, to prevent water stains thoroughly.2, if ordinary water leaves some dirt or grease, you can add a mild detergent water.

Send your message to us

304/316 seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords