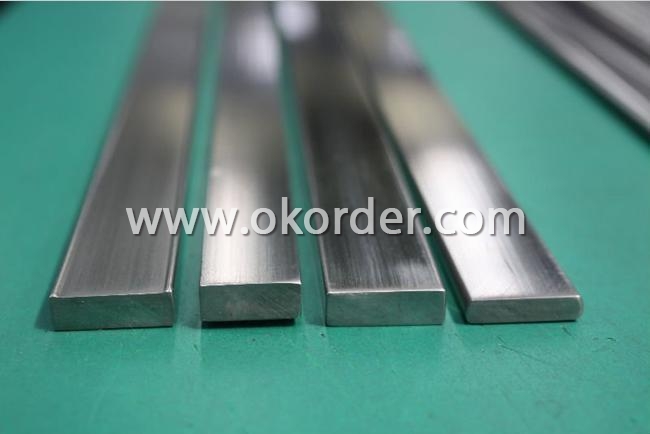

Stainless Steel Flats-XSTEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats-XSTEEL

Details of Stainless Steel Flat Bar:

Thickness: 3mm - 15mm

Width: 25mm - 120mm

Inch Thickness: 1/8" - 5/8"mm

Width: 1" - 4.1/2"mm

Standard: ASTM A276/484M ,EN 10058/DIN 1017

Advantages of Stainless Steel Flat Bar :

1* All products are made of high quality material

2* More than 300 patterns

3* Favouable price&Considerable service

4* Fast delivery

5* Quickest and most efficient response to your inquiry

Specifications of Stainless Steel Flat Bar :

1. Prime stainless steel bar

2. Raw materials from TG

3. Independent factory

4. Deliverd within 3-7 days

5. Best service

- Q: Can stainless steel pipes be used for brewery equipment?

- Yes, stainless steel pipes can definitely be used for brewery equipment. Stainless steel is a preferred material in brewery setups due to its excellent corrosion resistance, durability, and hygienic properties. It can handle the high temperatures, acidic content, and frequent cleaning required in brewery operations, making it a reliable choice for the construction of pipes used in brewing equipment.

- Q: Can stainless steel pipes be used for wastewater treatment ponds?

- Yes, stainless steel pipes can be used for wastewater treatment ponds. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and chemicals typically found in wastewater treatment facilities. It is a durable and long-lasting material that can effectively transport wastewater and withstand the demands of the treatment process.

- Q: Are stainless steel pipes suitable for heat exchangers?

- Yes, stainless steel pipes are suitable for heat exchangers. Stainless steel possesses excellent heat transfer properties and is resistant to corrosion and oxidation, making it an ideal material for heat exchanger applications. Its durability, high strength, and ability to withstand extreme temperatures make stainless steel pipes a reliable choice for efficient heat exchange.

- Q: Can stainless steel pipes be used in the food and beverage industry?

- Certainly, the food and beverage industry can utilize stainless steel pipes. Stainless steel is highly favored for piping in this sector because of its impressive resistance to corrosion, hygienic attributes, and long-lasting nature. By employing stainless steel pipes, there is no risk of any chemical reactions occurring between the pipes and the food or beverages, effectively preserving the products' integrity and safety during transportation. Furthermore, the ease of cleaning and maintenance of stainless steel pipes is of utmost importance in the food and beverage processing industry, where maintaining a high standard of sanitation is crucial. In summary, stainless steel pipes are extensively embraced and employed in the food and beverage industry due to their dependability and suitability for handling a diverse range of products.

- Q: Stainless steel works. What saw can be sawed off?

- What is the best or bad, to the building materials market to find a store with a chainsaw to help cut or site also if things go to the talent market, a hydraulic, electric what, give him a little money he will help you cut out

- Q: How do stainless steel pipes compare to polyethylene pipes?

- Stainless steel pipes have higher durability and strength compared to polyethylene pipes. They are resistant to corrosion, heat, and pressure, making them suitable for diverse applications in industries such as oil and gas, construction, and water treatment. On the other hand, polyethylene pipes are more flexible, lightweight, and cost-effective, making them ideal for underground water and gas distribution systems. The choice between stainless steel and polyethylene pipes depends on factors like the specific application, budget, and environmental conditions.

- Q: Can stainless steel pipes be used for structural applications?

- Yes, stainless steel pipes can be used for structural applications. Stainless steel is known for its high strength-to-weight ratio, corrosion resistance, and durability, making it a suitable material for various structural applications. Stainless steel pipes are commonly used in construction, infrastructure, and industrial projects, where the pipe's strength and resistance to corrosion are crucial. They are often used for structural supports, frameworks, and load-bearing applications in buildings, bridges, stadiums, and other structures. Additionally, stainless steel pipes have excellent structural integrity, allowing them to withstand heavy loads, extreme temperatures, and harsh environmental conditions. Therefore, stainless steel pipes are a reliable choice for structural applications.

- Q: Can stainless steel pipes be used in high-pressure applications?

- Yes, stainless steel pipes can be used in high-pressure applications. Stainless steel is known for its strength, durability, and ability to withstand extreme pressure conditions. It is often used in industries such as oil and gas, chemical processing, and power generation, where high-pressure environments are common. Stainless steel pipes offer excellent resistance to corrosion, making them suitable for long-term use in high-pressure applications.

- Q: What is the difference between 410 and 316 stainless steel pipes?

- The main difference between 410 and 316 stainless steel pipes lies in their composition and properties. 410 stainless steel is a magnetic, martensitic stainless steel with relatively high strength, hardness, and wear resistance. It is often used in applications where corrosion resistance is not a primary requirement, such as in tools, cutlery, and pump shafts. On the other hand, 316 stainless steel is an austenitic stainless steel that is non-magnetic and has excellent corrosion resistance, especially in harsh environments. It contains higher amounts of chromium and nickel, providing superior resistance to corrosion, pitting, and crevice corrosion. Due to its excellent properties, 316 stainless steel pipes are commonly used in industries such as chemical processing, marine, and food processing. In summary, while both 410 and 316 stainless steel pipes have their specific applications, 316 stainless steel offers superior corrosion resistance and is more suitable for environments where corrosion is a concern.

- Q: Can stainless steel pipes be insulated with fiberglass?

- Fiberglass insulation is a viable option for insulating stainless steel pipes. Its exceptional thermal resistance characteristics make it a popular choice for pipe insulation. By preventing heat loss or gain, it enhances energy efficiency. Moreover, fiberglass insulation is lightweight, simple to install, and can be easily customized to fit pipes of different sizes and shapes. It also offers excellent sound insulation properties and is non-combustible. Thus, fiberglass insulation is the ideal solution for insulating stainless steel pipes.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Flats-XSTEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords