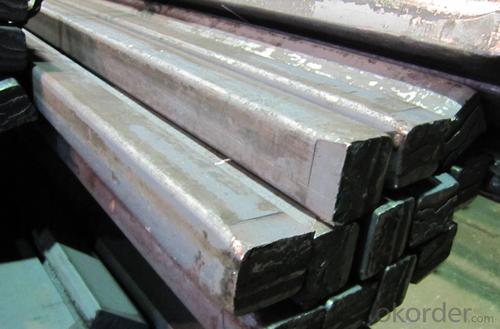

Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 85MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different methods of steel billet surface honing?

- There are several different methods of steel billet surface honing, each serving a specific purpose and achieving different results. Some of the common methods include: 1. Manual Honing: This traditional method involves using hand-held honing tools, such as stones or abrasive pads, to manually remove any imperfections or rough surfaces from the steel billet. Skilled operators carefully rub the honing tool along the surface of the billet until the desired smoothness is achieved. 2. Mechanical Honing: In this method, mechanical honing machines are used to automate the honing process. These machines are equipped with rotating abrasive stones or pads that move along the surface of the billet, removing any irregularities. Mechanical honing allows for a more consistent and precise honing process, with the ability to control factors such as pressure, speed, and contact area. 3. Diamond Honing: Diamond honing is a specialized method that utilizes diamond-coated tools to achieve a high level of precision and smoothness. The diamond particles on the honing tool provide superior cutting capabilities, allowing for the removal of even the smallest imperfections. This method is often used for honing high-quality steel billets that require a flawless surface finish. 4. Hydrohoning: Hydrohoning, also known as abrasive flow machining, involves using a viscous abrasive medium that is forced through the billet's internal passages to remove any surface irregularities. This method is especially effective for honing complex shapes or internal surfaces that are difficult to reach through other methods. The abrasive medium can be adjusted to achieve different levels of surface finish. 5. Electrochemical Honing: Electrochemical honing is a technique that combines the principles of electrochemical machining and honing. It involves using a special electrolyte solution and a honing tool with an electrode to remove material from the billet's surface. This method is effective for honing hard materials and achieving a smooth, mirror-like finish. These are just some of the different methods of steel billet surface honing. The choice of method depends on factors such as the desired surface finish, the complexity of the billet's shape, the material being honed, and the level of precision required.

- Q: What are the major steel billet producing countries?

- The major steel billet producing countries include China, India, Russia, Japan, and the United States.

- Q: What are the specifications for stainless steel billets used in the marine industry?

- The specifications for stainless steel billets used in the marine industry typically include a specific grade of stainless steel, such as 316 or 316L, which offers excellent corrosion resistance in marine environments. These billets are often required to meet certain standards, such as ASTM A276 or ASTM A484, which outline the chemical composition, mechanical properties, and dimensional tolerances for stainless steel products. Additionally, the billets may need to undergo specific heat treatment processes, such as annealing or solution treatment, to ensure optimal strength and corrosion resistance.

- Q: How are steel billets used in the manufacturing of medical equipment?

- Medical equipment manufacturing relies heavily on steel billets, which serve as a crucial raw material. These semi-finished steel products act as a starting point for various manufacturing processes. Within the medical equipment industry, steel billets are indispensable for producing a wide range of components and devices that are essential for healthcare professionals and patients. To begin with, stainless steel casting is a common process used to transform steel billets into stainless steel. This material is highly sought after in medical equipment manufacturing due to its exceptional corrosion resistance, durability, and hygienic properties. Surgical instruments like scalpels, forceps, and scissors, as well as implantable devices such as orthopedic implants, pacemakers, and stents, frequently utilize stainless steel. Moreover, precision machining is another method employed to manufacture medical equipment components from steel billets. By machining these billets into various shapes and sizes, connectors, valves, brackets, and frames for medical devices and equipment can be produced. The use of precision machining ensures that these components meet the stringent quality and dimensional requirements necessary for medical applications. Additionally, steel billets are utilized in the production of casings and enclosures for medical equipment. These components provide crucial protection and support for sensitive internal components, ensuring the durability and longevity of medical devices. Steel billets are commonly employed in creating casings for devices such as X-ray machines, CT scanners, and MRI machines, as well as smaller equipment like infusion pumps and monitors. Overall, steel billets play an essential role in medical equipment manufacturing by providing the necessary raw material for the production of components, casings, and instruments. The inherent properties of steel, including strength, durability, and corrosion resistance, make it an ideal material for medical applications. The utilization of steel billets guarantees the production of high-quality, reliable, and safe medical equipment, which is crucial for the healthcare industry.

- Q: What is the role of steel billets in the manufacturing of machinery?

- Steel billets play a crucial role in the manufacturing of machinery due to their versatile nature and desirable properties. These semi-finished steel products are essentially long, rectangular bars that serve as the raw material for producing various machinery components. Firstly, steel billets are known for their strength, durability, and excellent mechanical properties, making them ideal for the construction of heavy-duty machinery. By using high-quality billets, manufacturers can ensure that the resulting machinery will have the strength and structural integrity necessary to withstand the demanding operating conditions and loads. Secondly, steel billets can be easily molded and shaped into different forms and sizes through various manufacturing processes like forging, rolling, or extrusion. This versatility allows machinery manufacturers to create complex components with intricate designs, ensuring precision and functionality. Furthermore, the uniformity and consistency of steel billets contribute to the reliability and performance of machinery. As billets undergo a controlled cooling process during their production, they acquire a uniform microstructure, minimizing the risk of defects and improving the overall quality of the machinery components manufactured from them. Another important aspect is the machinability of steel billets, which refers to their ability to be easily cut, drilled, or shaped using machine tools. This property allows manufacturers to efficiently produce machinery components with precise dimensions and tolerances, saving time and costs in the manufacturing process. Moreover, steel billets can be heat-treated to enhance their mechanical properties, such as hardness, toughness, and resistance to wear or corrosion. This makes them suitable for critical machinery parts that require specific characteristics to ensure optimal performance and longevity. In summary, steel billets are indispensable in the manufacturing of machinery due to their strength, versatility, uniformity, and machinability. They provide the necessary raw material for producing robust and reliable machinery components that can withstand demanding conditions and meet the performance requirements of various industries.

- Q: What are the main challenges in the supply chain management of steel billets?

- There are several main challenges in the supply chain management of steel billets. 1. Demand fluctuations: The steel industry is highly sensitive to economic cycles and changes in global demand. Fluctuations in demand can lead to imbalances in the supply chain, causing excess inventory or shortages of steel billets. This uncertainty makes it challenging for supply chain managers to accurately forecast demand and optimize production and inventory levels. 2. Transportation and logistics: Steel billets are heavy and bulky, making transportation and logistics a major challenge. Efficient transportation networks need to be established to ensure timely delivery of steel billets to customers. Moreover, the handling and storage of steel billets require specialized equipment and facilities, which can add complexity and cost to the supply chain. 3. Supply chain visibility: Lack of visibility and transparency across the supply chain can lead to inefficiencies and delays. It is crucial for supply chain managers to have real-time information on inventory levels, production status, and transportation schedules. This enables them to make informed decisions and mitigate any potential disruptions in the supply chain. 4. Quality control: Maintaining consistent quality of steel billets throughout the supply chain is vital. Steel billets are often produced by different manufacturers, and variations in quality can occur. Supply chain managers need to implement robust quality control processes to ensure that only high-quality billets are delivered to customers. This may involve regular inspections, testing, and strict adherence to industry standards. 5. Sustainability and environmental concerns: The steel industry is under increasing pressure to reduce its carbon footprint and adopt sustainable practices. Supply chain managers face the challenge of implementing environmentally friendly processes and sourcing steel billets from suppliers that adhere to sustainable practices. This may involve evaluating the environmental impact of transportation methods, optimizing energy consumption during production, and ensuring responsible sourcing of raw materials. In summary, the main challenges in the supply chain management of steel billets include demand fluctuations, transportation and logistics, supply chain visibility, quality control, and sustainability concerns. Overcoming these challenges requires effective planning, collaboration with suppliers and customers, and the use of advanced technologies to improve visibility and optimize processes.

- Q: How do steel billets contribute to the corrosion resistance of a product?

- The corrosion resistance of a product is not directly affected by steel billets. Instead, it is determined by the specific composition and treatment of the steel billets. Steel billets are essentially semi-finished steel products that act as raw materials for various downstream processes like forging, rolling, and extrusion, which ultimately produce the final product. To improve the corrosion resistance of a product, specific alloying elements and controlled processing techniques can be used during the manufacturing of steel billets. For example, stainless steel billets have a higher chromium content, which creates a protective oxide layer called chromium oxide on the steel's surface. This oxide layer acts as a barrier, preventing direct contact between the steel and corrosive environments, thus enhancing the corrosion resistance of the final product. Additionally, steel billets can undergo further treatments like heat treatment, surface coatings, or galvanization to enhance their corrosion resistance. Heat treatment processes like annealing, quenching, or tempering can modify the microstructure of steel billets, resulting in improved corrosion resistance properties. Surface coatings like paint, powder coating, or electroplating can provide an additional layer of protection, preventing direct exposure to corrosive substances. Galvanization involves coating steel billets with a layer of zinc, which acts as a sacrificial anode, corroding instead of the underlying steel to protect it. In conclusion, while steel billets themselves do not directly contribute to the corrosion resistance of a product, the composition, alloying elements, and treatments applied during their manufacturing process play a crucial role in enhancing the corrosion resistance of the final product.

- Q: How are steel billets shaped into rods or wires?

- Steel billets are shaped into rods or wires through a process called hot rolling. Hot rolling involves passing the steel billets through a series of rollers at high temperatures. The first step is to heat the billets to a temperature above their recrystallization point, typically around 1200-1300 degrees Celsius. This temperature ensures that the steel is soft and malleable, making it easier to shape. Once the billets are heated, they are then fed through a series of rollers that gradually reduce their thickness and shape them into the desired rod or wire. These rollers apply pressure to the billets, causing them to elongate and decrease in thickness. The number of rollers and their configurations may vary depending on the specific requirements of the rod or wire being produced. During the hot rolling process, the steel undergoes plastic deformation due to the applied pressure and high temperatures. This plastic deformation allows the steel to change its shape without breaking or cracking. The continuous rolling and reduction of thickness gradually transform the billets into rods or wires. After the steel has been rolled to the desired size and shape, it is then cooled, typically through a process known as air cooling. This cooling process allows the steel to retain its new shape and hardness. The cooled rods or wires can then be further processed, such as through additional heat treatments or surface treatments, to enhance their properties and meet specific requirements. Overall, the hot rolling process is essential in shaping steel billets into rods or wires. It allows for the precise control of dimensions and properties while ensuring the final product meets the desired specifications.

- Q: What are the different types of steel billet welding processes?

- There are several different types of steel billet welding processes that are commonly used in various industries. These processes include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW involves a flux-coated electrode that is manually fed into the welding pool. It is a versatile and widely used process for welding steel billets. 2. Gas Metal Arc Welding (GMAW): This process, commonly known as MIG welding, uses a continuously fed wire electrode and a shielding gas to protect the weld pool. It is a popular method for welding steel billets due to its efficiency and ease of use. 3. Flux-Cored Arc Welding (FCAW): FCAW is similar to GMAW, but it uses a tubular electrode filled with flux instead of a solid wire. This process is often preferred for outdoor or windy conditions as the flux provides better protection against atmospheric contamination. 4. Submerged Arc Welding (SAW): SAW involves feeding a consumable electrode and a granular flux into the weld zone, while the arc remains submerged beneath a layer of flux. It is commonly used for welding large steel billets due to its high deposition rates and deep penetration capabilities. 5. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, GTAW uses a non-consumable tungsten electrode and a shielding gas to protect the weld pool. It is a precise and high-quality welding process suitable for thin steel billets or applications that require exceptional weld aesthetics. 6. Electroslag Welding (ESW): ESW is a highly efficient process used for welding thick steel billets. It involves melting a consumable electrode and the base metal in a molten slag pool, which provides protection and acts as a filler material. 7. Laser Beam Welding (LBW): LBW utilizes a high-energy laser beam to melt and join steel billets together. It is a precise and fast welding process commonly used in industries such as automotive and aerospace. Each of these welding processes has its own advantages and limitations, and the choice of process depends on factors such as the type and thickness of the steel billet, desired weld quality, production requirements, and cost considerations.

- Q: What are the different methods of steel billet testing?

- In the industry, multiple methods are commonly used to test steel billets, aiming to evaluate their quality and integrity before further processing or use in construction. Among the various methods are: 1. Visual Inspection: The surface of the steel billet is visually examined to identify any visible defects like cracks, surface irregularities, or signs of damage. 2. Ultrasonic Testing: By emitting high-frequency sound waves into the billet and analyzing the reflected waves, internal defects or inconsistencies in the steel billet are detected. 3. Magnetic Particle Inspection: This method detects surface or near-surface defects by applying magnetic particles to the billet's surface. If there are any defects, the particles will be attracted, forming easily detectable visible indications. 4. Eddy Current Testing: Electromagnetic induction is utilized in this non-destructive testing method to identify surface or near-surface defects. Changes in the magnetic field caused by irregularities or defects in the billet are detected and analyzed. 5. Chemical Analysis: The chemical composition of the steel billet is analyzed to ensure it meets the required specifications. Techniques such as spectroscopy or wet chemistry methods are typically employed to determine the levels of various elements present. 6. Tensile Testing: A small sample of the steel billet is subjected to tension until it breaks, allowing for the determination of tensile strength and other mechanical properties. This test provides valuable information regarding the overall strength and durability of the billet. 7. Hardness Testing: The hardness of the steel billet, an important property for determining its suitability for specific applications, is measured. Various hardness testing methods like Rockwell, Brinell, or Vickers hardness tests can be used. Each testing method has its own advantages and limitations, and the choice of method depends on the specific requirements and quality standards of the steel billet under examination.

Send your message to us

Q235/3SP 140MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords