PVC Waterproofing Plastic Membrane for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

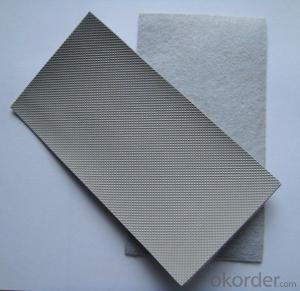

Product Description of PVC Waterproofing Plastic Membrane for Construction:

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope of PVC Waterproofing Plastic Membrane for Construction:

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering.

Product Category of PVC Waterproofing Plastic Membrane for Construction:

Single composite PVC waterproof materials

Double composite PVC waterproof board

Seperate PVC waterproof board

Some sticky type PVC waterproof materials

Technical Parameters of PVC Waterproofing Plastic Membrane for Construction:

No. | Item | Index | |||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10.0 | - | - | 10.0 | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

- Q: Can a waterproofing membrane be used in rooftop gardens or green roofs?

- Yes, a waterproofing membrane can be used in rooftop gardens or green roofs. It is an essential component to prevent water leakage and protect the underlying structure from moisture damage. The membrane acts as a barrier, preventing water from penetrating the roof and causing potential structural issues. This ensures that the rooftop garden or green roof remains well-maintained and functional.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- Yes, a waterproofing membrane can help protect against mold or mildew growth. Mold and mildew thrive in damp and moist environments, and a waterproofing membrane creates a barrier that prevents water from seeping into the building structure. By keeping the area dry, it greatly reduces the chances of mold or mildew growth. Additionally, waterproofing membranes often have anti-microbial properties that inhibit the growth of mold and mildew even further. However, it's important to note that while a waterproofing membrane can provide significant protection against mold and mildew, it is not a foolproof solution. Proper ventilation and regular maintenance are also essential to prevent these issues.

- Q: Can a waterproofing membrane be used for wastewater treatment plants or sewage facilities?

- Indeed, wastewater treatment plants and sewage facilities require protection against water infiltration and leakage due to the abundance of water and potentially corrosive substances. To address this issue, a versatile solution in the form of a waterproofing membrane can be utilized. This membrane acts as a barrier, preventing water penetration and safeguarding the structure from damage while ensuring the facility's proper functioning. Its application extends to various areas such as walls, floors, roofs, and tanks, effectively maintaining a watertight environment and prolonging the facility's lifespan. Moreover, certain waterproofing membranes are specifically engineered to withstand harsh chemicals, making them ideal for wastewater treatment plants and sewage facilities where corrosive substances may be present.

- Q: Can a waterproofing membrane be used for a basement floor?

- A basement floor can indeed benefit from the use of a waterproofing membrane. These membranes are specifically engineered to halt the infiltration of water, safeguarding the underlying structure. When applied to the basement floor, the membrane acts as a barrier, effectively keeping the surface dry and shielding it from water damage. This is particularly crucial for basements, which are prone to water seepage due to their subterranean location. Furthermore, a waterproofing membrane also aids in curtailing the growth of mold and mildew, as it effectively seals out moisture. It is of utmost importance to select a top-notch waterproofing membrane that is explicitly designed for basement floors and to meticulously adhere to the manufacturer's instructions for proper installation.

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Yes, a waterproofing membrane can be used on precast nickel surfaces. The membrane will provide a protective barrier against water penetration, helping to prevent moisture damage and corrosion on the nickel surface.

- Q: Can a waterproofing membrane be used for concrete bridge decks?

- Yes, a waterproofing membrane can be used for concrete bridge decks. A waterproofing membrane is a thin layer of material that is applied to the surface of the bridge deck to prevent water infiltration and protect the concrete from deterioration caused by moisture. This membrane is designed to be flexible and durable, providing a barrier against water while allowing for the movement and expansion of the bridge deck. It is typically applied in multiple layers and can be either hot-applied or cold-applied, depending on the specific project requirements. The use of a waterproofing membrane on concrete bridge decks helps to extend the service life of the structure by preventing water damage, reducing the need for frequent repairs and maintenance, and improving overall structural integrity.

- Q: Can a waterproofing membrane be used on PVC roofs?

- Yes, a waterproofing membrane can be used on PVC roofs. PVC roofs are commonly used in commercial and residential buildings, and applying a waterproofing membrane can provide an additional layer of protection against water damage and leaks. The membrane is typically made of materials such as synthetic rubber or thermoplastic that are specifically designed to prevent water penetration. By installing a waterproofing membrane on a PVC roof, it can enhance its durability and extend its lifespan.

- Q: Are waterproofing membranes suitable for residential applications?

- Indeed, residential applications can benefit greatly from the use of waterproofing membranes. These membranes find widespread use in a variety of residential construction areas, including basements, foundations, roofs, bathrooms, and balconies. Their primary purpose is to safeguard the building structure by preventing water penetration and moisture damage. Waterproofing membranes function as a barrier that effectively blocks water from infiltrating the structure, thereby averting problems such as mold growth, rot, or structural deterioration. These membranes commonly consist of materials such as bitumen, PVC, EPDM, or polyurethane, which possess exceptional water-repelling properties. During the construction or renovation process of residential buildings, waterproofing membranes are typically installed. They can be applied in the form of liquid coatings or sheets that are meticulously laid down and firmly affixed to the surface. These membranes create a seamless and long-lasting barrier that can withstand the test of time. Moreover, waterproofing membranes offer numerous advantages for residential applications. They help maintain a dry and comfortable living environment by preventing water leaks and dampness. As a result, they safeguard the integrity of the building materials, extend the lifespan of the structure, and minimize the likelihood of expensive repairs. Furthermore, these membranes contribute to enhanced energy efficiency by reducing heat loss or gain caused by moisture infiltration. By effectively blocking water, they assist in maintaining consistent temperatures inside the house, which leads to reduced energy consumption and lower utility bills. In conclusion, waterproofing membranes are an exceptional choice for residential applications. They provide dependable protection against water damage, enhance the longevity of the structure, and contribute to a healthier and more energy-efficient living environment.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels?

- Certainly, it is possible to utilize a waterproofing membrane in regions with elevated groundwater levels. In truth, it is strongly advised to employ a waterproofing membrane in such areas to safeguard the integrity of the edifice from water penetration. The primary purpose of a waterproofing membrane is to construct a barrier that hinders the ingress of water into the building or structure. This becomes particularly crucial in zones with high groundwater levels due to the substantial pressure exerted by the water, which heightens the chances of water damage or flooding. By implementing a waterproofing membrane, you can effectively minimize the risk of water infiltration and ensure the long-lasting resilience of the structure.

- Q: Can a waterproofing membrane be used in foundations?

- Foundations can benefit from the use of a waterproofing membrane. Installing such a membrane is often recommended to prevent water infiltration and protect the structure from potential damage. This barrier is typically applied to the exterior walls of the foundation, effectively blocking water penetration. By keeping the foundation dry, it safeguards against cracks and leaks caused by hydrostatic pressure. Moreover, a waterproofing membrane helps prevent moisture buildup, mold growth, and other water damage-related issues. Overall, incorporating a waterproofing membrane in foundations is a dependable and effective approach to ensure the long-lasting stability and durability of a building.

Send your message to us

PVC Waterproofing Plastic Membrane for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords