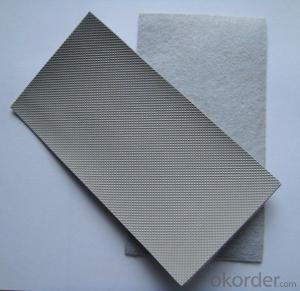

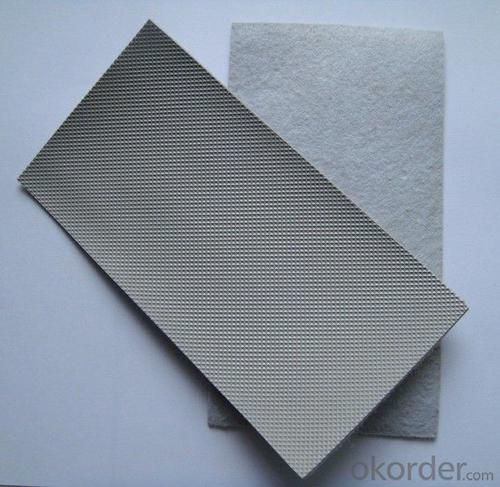

PVC Waterproofing Membrane for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for PVC Waterproofing Membrane

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

1.Technical data of PVC Membrane

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

2.Characteristic of PVC Membrane

1.Strong tensile strength, high elongation, can fit big deformation of substrates.

2.Excellent anti-extreme weather property, can adapt to various environment temperature difference.

3.Suitable for exposed projects with long lifetime and good anti-aging property.

4.Can be welded firmly and reliably.

5.Outstanding root penetration resistance, best choice for planted roofs.

6.Simple and fast construction without pollution.

7.Great plasticity and fast treatment with corners and details.

3.Applicable scope of PVC Membrane

PVC sheet forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway& tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

4. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- A waterproofing membrane is capable of protecting against the growth of mold or mildew, as they thrive in environments that are damp and moist. The membrane acts as a barrier, preventing water from entering the building structure. This effectively keeps the area dry and greatly reduces the likelihood of mold or mildew growth. Furthermore, waterproofing membranes often contain anti-microbial properties that further hinder the growth of mold and mildew. Nevertheless, it is important to remember that while a waterproofing membrane can offer substantial protection against mold and mildew, it is not a foolproof solution. It is crucial to ensure proper ventilation and carry out regular maintenance to prevent these issues.

- Q: Can a waterproofing membrane be used for plaza decks?

- Plaza decks necessitate safeguarding against water infiltration to avoid harm to the underlying structure. This is where the application of a waterproofing membrane comes into play. These membranes are specifically designed to create a barrier, preventing water from permeating the deck and causing issues like leaks, deterioration, and structural damage. Typically composed of materials such as bitumen, rubber, or polyurethane, these membranes boast high resistance against water penetration. By incorporating a waterproofing membrane onto a plaza deck, it ensures the deck remains impervious to water, thereby preserving the integrity of the entire structure. Furthermore, these membranes offer additional advantages such as UV resistance, durability, and easy maintenance, rendering them an ideal solution for plaza decks.

- Q: Are waterproofing membranes resistant to mineral oils?

- Waterproofing membranes can vary in their resistance to mineral oils. Some waterproofing membranes are specifically designed to be resistant to mineral oils, while others may not be. It is important to check the specifications and product information provided by the manufacturer to determine the resistance of a particular waterproofing membrane to mineral oils. Additionally, it is recommended to consult with a professional or the manufacturer directly for specific guidance on the compatibility of a waterproofing membrane with mineral oils in your specific application.

- Q: Can a waterproofing membrane be used in areas with high humidity and moisture?

- Indeed, the utilization of a waterproofing membrane is viable in areas characterized by high levels of humidity and moisture. The primary purpose of this membrane is to avert water infiltration and safeguard the underlying structure against any detrimental effects caused by moisture. Areas such as basements, bathrooms, and kitchens, where moisture and humidity are more prevalent, frequently employ waterproofing membranes. These membranes establish a barrier that obstructs water from permeating through walls, floors, or roofs, and they are typically composed of materials like rubber, asphalt, or PVC. By incorporating a waterproofing membrane, one can proficiently regulate moisture levels and shield their property from potential water damage, mold growth, and other associated complications.

- Q: Can a waterproofing membrane be used for a crawl space?

- Yes, a waterproofing membrane can be used for a crawl space. It can help prevent moisture from seeping into the crawl space, protecting the area from water damage and potential mold growth.

- Q: Does a waterproofing membrane require any protective coatings or sealants?

- Yes, a waterproofing membrane generally requires some form of protective coatings or sealants to enhance its performance and durability. While the membrane itself provides a level of waterproofing, it may not be sufficient to withstand all environmental conditions or potential damage. Applying protective coatings or sealants on top of the membrane helps to create an additional barrier against water intrusion, UV radiation, mechanical stress, and chemical exposure. These coatings or sealants can also provide added flexibility, strength, and protection against wear and tear. It is essential to consult with a professional waterproofing specialist to determine the appropriate type of coating or sealant that suits the specific membrane and project requirements.

- Q: Can waterproofing membranes be used on parking decks?

- Yes, waterproofing membranes can be used on parking decks. Parking decks are exposed to various weather conditions and are subject to constant vehicle traffic, which can lead to water penetration and damage. Waterproofing membranes provide a protective barrier against water infiltration, preventing moisture from seeping into the structure and causing deterioration. These membranes are designed to withstand heavy loads and resist the chemicals found in automotive fluids, making them an ideal solution for parking decks. By applying waterproofing membranes, the lifespan of the parking deck can be extended, reducing the need for costly repairs and ensuring the safety and integrity of the structure.

- Q: What is the typical installation process for a waterproofing membrane?

- The typical installation process for a waterproofing membrane involves several steps. First, the surface that needs to be waterproofed is thoroughly cleaned and prepared. This may involve removing any existing coatings, debris, or loose materials from the surface. It is important to ensure that the surface is smooth, clean, and free from any contaminants that could affect the adhesion of the membrane. Next, any cracks, holes, or imperfections in the surface are repaired. This may involve filling in cracks with a suitable filler or patching compound, and smoothing out any rough areas. It is crucial to have a solid and even surface to ensure the proper installation and effectiveness of the waterproofing membrane. Once the surface is prepared, a primer is often applied. The primer helps to improve the adhesion between the surface and the membrane. It is typically applied with a brush or roller, following the manufacturer's instructions. After the primer has dried, the waterproofing membrane is installed. There are different types of membranes available, such as sheet membranes or liquid-applied membranes. Sheet membranes are typically rolled out onto the surface and adhered using a suitable adhesive or mortar. Liquid-applied membranes are applied using a brush, roller, or spray equipment, creating a continuous and seamless barrier. During the installation process, it is important to ensure that the membrane is installed correctly, with proper overlap or seams, and that any penetrations or transitions are properly treated and sealed. This includes areas such as corners, edges, drains, and pipe penetrations, where additional detailing may be required to create a watertight seal. Once the membrane is installed, it is important to allow it to cure or dry according to the manufacturer's instructions. This ensures that the membrane reaches its full strength and waterproofing capabilities. Finally, after the membrane has cured, a protective layer or coating may be applied to further enhance the durability and longevity of the waterproofing system. This may involve applying a topcoat, sealant, or protective barrier to protect the membrane from UV rays, foot traffic, or other potential sources of damage. Overall, the typical installation process for a waterproofing membrane involves surface preparation, application of a primer, installation of the membrane, detailing and sealing, curing, and potentially applying a protective layer. It is important to follow the manufacturer's instructions and consult with a professional if necessary to ensure a proper and effective installation.

- Q: Are waterproofing membranes resistant to acid rain?

- Waterproofing membranes, in general, exhibit resistance against acid rain. These membranes are designed to create a barrier against the infiltration of water and are typically constructed using materials that can withstand various environmental factors, including acid rain. Acid rain is formed when water vapor in the atmosphere reacts with sulfur dioxide and nitrogen oxide pollutants, resulting in the production of sulfuric and nitric acids. Over time, these acids can corrode and harm certain materials. However, waterproofing membranes are engineered with the specific purpose of enduring acid rain and other environmental pressures. They are commonly composed of materials like modified bitumen, thermoplastic polyolefin (TPO), ethylene propylene diene monomer (EPDM), or polyvinyl chloride (PVC), which possess a high degree of resistance to acid rain. Furthermore, some waterproofing membranes may incorporate additional protective coatings or additives to enhance their capacity to withstand acid rain, ensuring long-lasting durability and performance. Nevertheless, it is important to bear in mind that the precise level of acid rain resistance of a waterproofing membrane may vary based on the specific product and manufacturer. Consequently, it is always advisable to consult the manufacturer's guidelines or specifications for accurate information.

- Q: What are the advantages and disadvantages of waterproofing membrane?

- There are many types of waterproofing membrane, mostly flexible waterproofing membrane. Such as: SBS coil, PVC, EVA, ECB The advantages of the coil is simple operation, do not need any valuable equipment, the basic is the torch, hot melt welding machine, are not expensive, the shortcomings of the base is a higher demand, it is easy to be damaged, resulting in structural leakage.

Send your message to us

PVC Waterproofing Membrane for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords