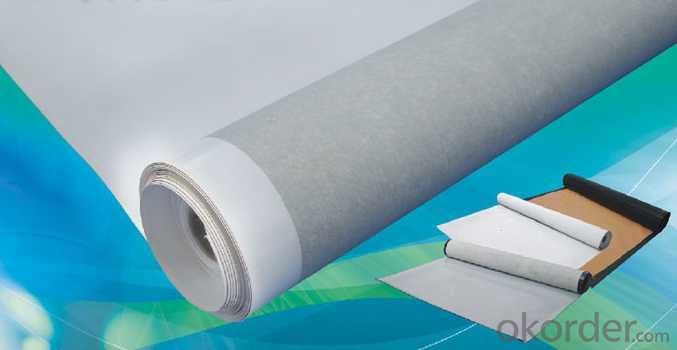

PVC Polymer Waterproofing Membrane for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

This membrane is polyester reinforced, which provides high breaking and tearing strength needed to prevent excessive elongation and sheet deformation under the stresses produced by the lifting of the membrane under wind loads. The unique lacquer coating provides the membrane with an easy to clean surface and prolongs the life of the membrane by reducing plasticiser loss.

Features

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

Specification

No. | Item | L | N | W | ||||

I | II | I | II | I | II | |||

1 | Tensile strength N/cm ≥ | 100 | 160 | 8 | 12 | 100 | 160 | |

2 | fracture elongation %≥ | 150 | 200 | 200 | 200 | 150 | 200 | |

3 | Dimension Changing at heating %≤ | 1.5 | 1 | 3 | 2 | 1.5 | 1 | |

4 | Foldability at low temperature °C | -20 | -25 | -20 | -25 | -20 | -25 | |

5 | Water tightness | No leakage | No leakage | No Leakage | ||||

6 | Joint shear resistance (N/mm)≥ | 3 | 3 | 6 | ||||

7 | Thermal Ageing treatment | Appearance | no bubble | no bubble | no bubble | |||

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

8 | Chemical corrosion resistance | foldability at low temperature °C | -15 | -20 | -15 | -20 | -15 | -20 |

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

9 | Artificial climate accelerated aging | foldability at low temperature °C | -15 | -20 | -15 | -20 | -15 | -25 |

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

Applications

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

RFQ

1. What is your MOQ?

--Our MOQ is 5000 m2

2. Can you provide sample?

--Yes, samples are in stock. we can offer free sample for you.

3. Do you offer OEM service?

--Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can a waterproofing membrane be used in areas with vehicular traffic?

- Certainly! It is indeed possible to utilize a waterproofing membrane in regions frequented by vehicles. In reality, there exist distinct variants of waterproofing membranes meticulously crafted to endure the pressure and motion exerted by automobiles. These specialized membranes, referred to as vehicular or traffic-bearing membranes, are generally composed of sturdier materials like rubberized asphalt or modified bitumen. They are purposefully engineered to furnish a robust and flexible barricade against water and moisture, whilst simultaneously withstanding the burdensome loads and incessant traffic commonly associated with vehicles. Vehicular membranes find widespread application in parking garages, bridges, and other sites where vehicles are commonly found.

- Q: Can a waterproofing membrane be painted over?

- Yes, a waterproofing membrane can be painted over. However, it is important to ensure that the membrane is clean, dry, and free from any debris or loose material before applying paint. Additionally, it is recommended to use a paint that is specifically designed for use on waterproofing membranes to ensure proper adhesion and longevity. It is also important to follow the manufacturer's instructions for both the waterproofing membrane and the paint to ensure compatibility and effectiveness.

- Q: Can a waterproofing membrane be used in conjunction with expansion joint systems?

- The use of a waterproofing membrane can be combined with expansion joint systems. These membranes are frequently employed to prevent the infiltration of water and safeguard structures against moisture damage. In contrast, expansion joint systems are put in place to enable movement and accommodate thermal expansion and contraction in structures. By utilizing both a waterproofing membrane and expansion joint systems, it is feasible to provide both waterproofing and movement accommodation in a structure. This guarantees that the structure is shielded from water damage while still permitting necessary movement. It is crucial to design and install both the waterproofing membrane and the expansion joint system properly to ensure their compatibility and effectiveness.

- Q: Can a waterproofing membrane be used for wastewater treatment plants?

- Yes, a waterproofing membrane can be used for wastewater treatment plants. Waterproofing membranes are commonly used in various construction projects, including wastewater treatment plants, to provide a protective barrier against water infiltration. These membranes are designed to prevent water from seeping into the structure, which is crucial for wastewater treatment plants as they deal with large volumes of water. Wastewater treatment plants are exposed to constant water exposure and high humidity levels, which can lead to moisture damage and structural deterioration. By installing a waterproofing membrane, the facility can effectively prevent water penetration, ensuring the integrity and longevity of the structure. Furthermore, wastewater treatment plants often contain various corrosive chemicals and substances that can cause damage to the structure over time. Waterproofing membranes can act as a protective layer, preventing these chemicals from corroding the building materials and causing structural issues. There are different types of waterproofing membranes available, including sheet membranes, liquid membranes, and cementitious membranes. The choice of membrane depends on the specific requirements, budget, and conditions of the wastewater treatment plant. It is essential to select a membrane that is compatible with the chemicals present in the wastewater and can withstand the harsh conditions of the facility. In conclusion, a waterproofing membrane is a suitable solution for wastewater treatment plants as it effectively protects the structure from water infiltration and chemical damage. By implementing a proper waterproofing system, the facility can ensure the long-term durability and functionality of the plant.

- Q: Can a waterproofing membrane be used in conjunction with energy-efficient building designs?

- Yes, a waterproofing membrane can be used in conjunction with energy-efficient building designs. In fact, it is often recommended to have a waterproofing membrane as part of energy-efficient building designs, as it helps to protect the building from moisture infiltration and potential damage. By preventing water penetration, the membrane helps maintain the integrity of the building envelope, thus optimizing the energy performance and overall efficiency of the structure.

- Q: Can a waterproofing membrane be applied to concrete?

- Yes, a waterproofing membrane can be applied to concrete. It is a common method used to prevent water infiltration and protect the concrete structures from damage caused by moisture.

- Q: Are there any drawbacks or limitations to using a waterproofing membrane?

- Yes, there are some drawbacks and limitations to using a waterproofing membrane. One limitation is that the installation process can be time-consuming and labor-intensive. Waterproofing membranes often require careful surface preparation and multiple layers, which can be time-consuming and may require skilled labor. This can increase the overall cost of the project. Another limitation is that waterproofing membranes may not be suitable for all surfaces. Some membranes are designed specifically for certain types of substrates, such as concrete or metal, and may not adhere properly to other materials. It is important to select the appropriate type of membrane for the specific surface to ensure proper adhesion and effectiveness. Additionally, waterproofing membranes can be sensitive to environmental conditions. Extreme temperature fluctuations, UV exposure, and chemical exposure can degrade the membrane over time, reducing its effectiveness. Regular inspections and maintenance may be required to ensure the longevity of the membrane. Furthermore, waterproofing membranes can be susceptible to damage during installation or from external factors such as foot traffic or heavy objects. Punctures, tears, or improper installation can compromise the integrity of the membrane and reduce its ability to prevent water infiltration. Lastly, waterproofing membranes may not completely prevent water penetration in certain situations. For example, if there are existing cracks or structural issues in the substrate, water may still find a way to seep through, bypassing the membrane. It is important to address any underlying structural issues before applying the membrane to ensure optimal performance. Overall, while waterproofing membranes offer many benefits in terms of protecting against water damage, it is crucial to consider these limitations and drawbacks to make an informed decision about their use in specific applications.

- Q: Can a waterproofing membrane be used in schools or educational buildings?

- Yes, a waterproofing membrane can definitely be used in schools or educational buildings. Waterproofing membranes are designed to prevent water penetration and protect the building structure from moisture damage. In educational buildings, where a large number of students and staff gather, it is crucial to maintain a safe and healthy environment. Waterproofing membranes can be used in various areas such as basements, roofs, walls, and foundations to prevent water leakage, dampness, and mold growth. By installing a waterproofing membrane, schools can ensure the longevity of their buildings, protect valuable equipment and resources, and provide a comfortable learning environment for students and staff.

- Q: Are waterproofing membranes suitable for bridge abutments?

- Yes, waterproofing membranes are suitable for bridge abutments. Bridge abutments are the structures that support the ends of a bridge, and they are typically exposed to a significant amount of moisture and water. Waterproofing membranes are designed to provide a protective barrier against water and moisture intrusion, making them an ideal solution for bridge abutments. These membranes are typically made from materials such as bitumen, PVC, or EPDM, which are highly resistant to water penetration. Additionally, waterproofing membranes can also provide protection against other factors such as UV rays, chemicals, and temperature fluctuations. By installing waterproofing membranes on bridge abutments, the risk of water damage, deterioration, and corrosion can be significantly reduced, leading to increased durability and longevity of the bridge structure.

- Q: How does a waterproofing membrane handle movement or settling of the structure?

- A waterproofing membrane is designed to accommodate the movement or settling of a structure in a few different ways. Firstly, a waterproofing membrane is typically flexible and elastomeric, meaning it can stretch and move with the structure without cracking or tearing. This allows it to withstand minor shifts or settlements in the building without compromising its ability to keep water out. Additionally, some waterproofing membranes have built-in reinforcing materials, such as polyester or fiberglass, which provide added strength and durability. These reinforcements help the membrane resist potential damage caused by movement, settling, or even structural vibrations. Furthermore, many waterproofing systems include provisions for expansion joints or movement joints, which are intentionally created gaps or spaces in the structure to allow for natural movement. These joints are then sealed using flexible materials compatible with the waterproofing membrane. This allows the membrane to accommodate the anticipated movement or settling within these joints, preventing leaks or damage to the water barrier. In summary, a waterproofing membrane is designed to handle movement or settling of a structure by being flexible, elastomeric, and capable of stretching without tearing. Additionally, reinforcements and the incorporation of expansion joints further enhance the membrane's ability to accommodate movements and maintain its integrity as a waterproof barrier.

Send your message to us

PVC Polymer Waterproofing Membrane for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords